| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Forged Grinding Balls |

|---|---|

| Brand Name: | DRAGON STEEL BALLS |

| Model Number: | 45# 60Mn B2 B3 |

| Certification: | CE,ISO |

| Place of Origin: | CHINA |

| MOQ: | 1 ton |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 3000 tons / Month |

| Delivery Time: | 3-7 work days/ 25 tons |

| Packaging Details: | Container bags ,steel drums |

| Product Name: | Steel Balls For Ball Mill |

| Advantage: | High Wear Resistant,High Hardness,Low Price |

| Process: | Air Hammer Forging |

| Usagae: | Ball Mill for Mining,Cement plant,Power Station |

| Port: | Tianjin/Qingdao/Shanghai |

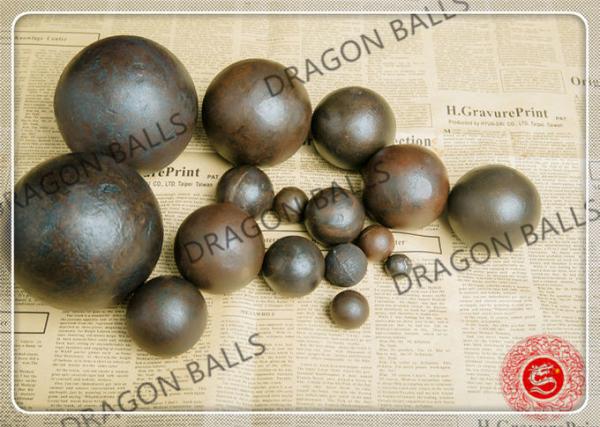

| Size: | Dia 20mm-200mm,1inch-8inch,1"-8" |

| Type: | Round Steel |

| Hardness: | 48-65 |

| Impact: | ≥12 Ak.J/cm2 |

| Tolerance: | Accrording to the different size |

| Company Info. |

| Jinan Dragon Steel Balls Co.,Ltd |

| View Contact Details |

| Product List |

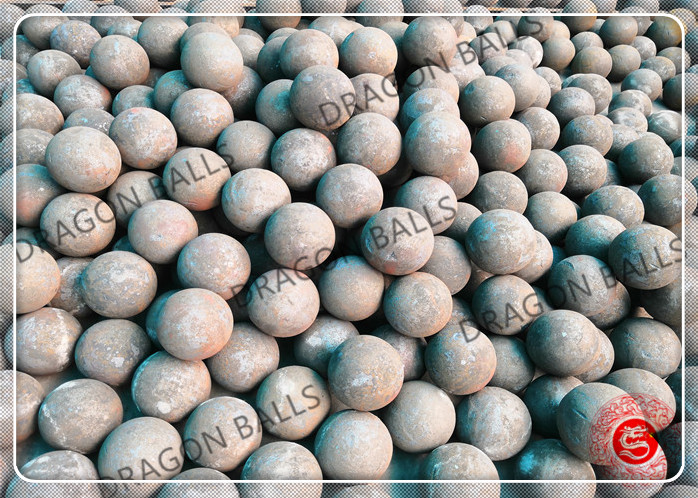

50mm Air Hammer Forged Grinding Balls Forging Steel Balls For Ball Mill

1. Steel Balls For Ball Mill Application

Forged grinding balls are used in ball mills, mainly in mines, cement plants, power plants and so on.

2. Classification

According to the different chemical elements , forging grinding balls can be divided into C45,60Mn,B2 and B3. At present, the above four materials are widely used all over the world, that’s the conventional materials, if there are special needs, can be customized.

3. Manufacturing process,

Forged grinding ball is forged by air hammer after being heated by electric furnace.

4. Steel Balls For Ball Mill Detail Specifications

① Chemical Composition

Material | Chemical Composition | |||||||

C | Si | Mn | Cr | P | S | Ni | Cu | |

C45 | 0.42-0.5 | 0.17-0.37 | 0.5-0.8 | ≤0.25 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 |

60Mn | 0.55-0.65 | 0.17-0.37 | 0.7-1.0 | ≤0.25 | <0.04 | <0.04 | ≤0.3 | ≤0.25 |

B2 | 0.72-0.85 | 0.17-0.37 | 0.7-1.0 | 0.4-0.6 | ≤0.025 | ≤0.025 | ≤0.02 | ≤0.02 |

B3 | 0.58-0.66 | 1.3-1.9 | 0.65-0.8 | 0.7-0.9 | ≤0.025 | ≤0.025 | ≤0.02 | ≤0.02 |

② Hardness

Size | C45 | 60Mn | B2 | B3 |

| 20mm | 55-58 | 58-62 | 60-64 | 62-65 |

| 30mm | 55-58 | 58-62 | 60-64 | 62-65 |

| 40mm | 55-58 | 58-62 | 60-64 | 62-65 |

| 50mm | 55-58 | 58-62 | 60-64 | 62-65 |

| 60mm | 55-58 | 58-62 | 60-64 | 62-65 |

| 70mm | 53-56 | 58-62 | 60-64 | 61-63 |

| 80mm | 53-56 | 58-62 | 59-63 | 60-65 |

| 90mm | 50-55 | 58-62 | 57-61 | 60-65 |

| 100mm | 48-52 | 57-61 | 56-60 | 60-65 |

| 110mm | 48-52 | 57-61 | 55-60 | 58-64 |

| 120mm | 48-52 | 57-61 | 55-60 | 56-63 |

| 130mm | 48-52 | 57-61 | 55-60 | 56-63 |

| 140mm | 48-52 | 57-61 | 55-60 | 56-63 |

| 150mm | 48-52 | 57-61 | 55-60 | 56-63 |

③ Weight

| Size(mm) | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130 | 140 | 150 |

| Weight(kg) | 0.033 | 0.111 | 0.261 | 0.512 | 0.883 | 1.402 | 2.092 | 2.98 | 1.087 | 5.44 | 7.062 | 9.008 | 11.25 | 13.83 |

5. Test

① Factory test

Forged grinding balls test is an very important step. Real-time detection will be carried out in the production process. Balls produced in each shift will be sampled in large quantities and tested for size, hardness, chemical composition, drop test, core pulling and impact value to ensure the quality of steel balls.

② The third party test

According to the customer different demand, forged grinding balls can be tested by any third party.

Steel Balls For Ball Mill

|