| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Pharmaceutical Granulation Equipments |

|---|---|

| Brand Name: | HUALIAN PHARMD |

| Model Number: | FD-ZLG |

| Certification: | ISO,GMP |

| Place of Origin: | CHINA |

| MOQ: | 1 Set |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 80 |

| Delivery Time: | 15 Set/Sets per Month |

| Packaging Details: | standard wooden case |

| Model No: | FD-ZLG |

| ETemperature of inlet air (℃): | 70~140 |

| Temperature of outlet (℃): | 40~70 |

| Weight(Kg): | 1250 |

ZLG Series Rectilinear Vibrating-Fluidized Dryer

Product overview:

Principle:

Application:

1. Pharmaceutical and chemical industries :all kinds of granular

tablet and granule,boric acid,borax dihydroxy benzene, malic acid,

maleic acid and so on;

2. Foodstuff and construction material industries : less, monsodium

glutamate,edible sugar, edible salt, mine residue, bean, seeds and

so on;

3. It can also used for raw materials to add up damp or cooling and

so on;

4. Cellulose: carboxymethyl cellulose cmc of.

Technical characters:

1. Due to the imposed vibration can make the minimum flow of the

gas velocitydecreased, and thus can significantly reduce the air

requirement, therebyreducing dustentrainment, supporting heat,

blower, cyclone separator can also becorrespondinglynarrow

specifications, complete sets of equipment cost will bedecreased

subtantillysignificant energy saving effect.

2. Can be easily rely on to adjust the vibration parameters to

change the materialresidence time in the machine. The pistonflow

run to reduce the particlesize uniformity and regularity. easy to

obtain uniform drying products.

3. Help material dispersed by vibration, such as to select the

appropriate vibrationparameters, the ordinary fluidized bed

agglomeration or materials likely togeneratechanneling the smooth

flow of dry.

4. As the intense back mixing, air velocity is low compared to

ordinary fluidized bedmaterial particle damage. Consumable

materials, and asked not to damage thecrystalor particle surface

brightness requirements of the most suitable materialduring the

drying process.

Main Technical Parameter:

| Model | Area of fluidized-bed(㎡) | ETemperature of inlet air (℃) | Temperature of outlet (℃) | Capacity to vapormoisture(kg/h) | Vibration motor | |

| Model | Model | |||||

| ZLG3x 0.30 | 0.9 | 70~140 | 40~70 | 20~35 | ZDS31- 6 | 0.8x 2 |

| ZLG4.5x0.30 | 1.35 | 35~ 50 | ZDS31- 6 | 0.8x 2 | ||

| ZLG4.5x0.45 | 2.025 | 50~ 70 | ZDS32- 6 | 1.1x2 | ||

| ZLG4.5x0.60 | 2.7 | 70~ 90 | ZDS32- 6 | 1.1x2 | ||

| ZLG6x0.45 | 2.7 | 80~ 100 | ZDS41- 6 | 1.5x2 | ||

| ZLG6x0.60 | 3.6 | 100~ 130 | ZDS41- 6 | 1.5x2 | ||

| ZLG6x0.75 | 4.5 | 120~ 140 | ZDS42- 6 | 2.2x 2 | ||

| ZLG6x0.9 | 5.4 | 140~1 70 | ZDS42- 6 | 2.2x 2 | ||

| ZLG7.5x0.6 | 4.5 | 130~ 150 | ZDS42- 6 | 2.2x 2 | ||

| ZLG7.5x0.75 | 5.625 | 150~ 180 | ZDS51- 6 | 3.0x 2 | ||

| ZLG7.5x0.9 | 6.75 | 160~ 210 | ZDS51- 6 | 3.0x 2 | ||

| ZLG7.5x1.2 | 9.0 | 200~ 280 | ZDS51- 6 | 3.0x 2 | ||

Dimension(mm)/Model | A | B | C | D | E | F | Weight(Kg) |

| ZLG3 X 0.30 | 3000 | 300 | 1350 | 900 | 430 | 1650 | 1250 |

| ZLG4.5x 0.30 | 4500 | 300 | 1350 | 900 | 430 | 1650 | 1560 |

| ZLG4.5x0.45 | 4500 | 450 | 1550 | 950 | 430 | 1700 | 1670 |

| ZLG4.5x0.60 | 4500 | 600 | 1650 | 950 | 430 | 1700 | 1910 |

| ZLG6x0.45 | 6000 | 450 | 1650 | 950 | 430 | 1700 | 2100 |

| ZLG6x0.60 | 6000 | 600 | 1700 | 1000 | 500 | 1700 | 2410 |

| ZLG6x0.75 | 6000 | 750 | 1850 | 1000 | 600 | 1850 | 2340 |

| ZLG6x0.9 | 6000 | 900 | 2000 | 1000 | 600 | 1850 | 3160 |

| ZLG7.5x0.6 | 7500 | 600 | 1850 | 1000 | 600 | 1850 | 3200 |

| ZLG7.5x0.75 | 7500 | 750 | 2000 | 1000 | 600 | 1850 | 3600 |

| ZLG7.5x0.9 | 7500 | 900 | 2100 | 1000 | 600 | 1850 | 4140 |

| ZLG7.5x1.2 | 7500 | 1200 | 2500 | 1150 | 800 | 2050 | 5190 |

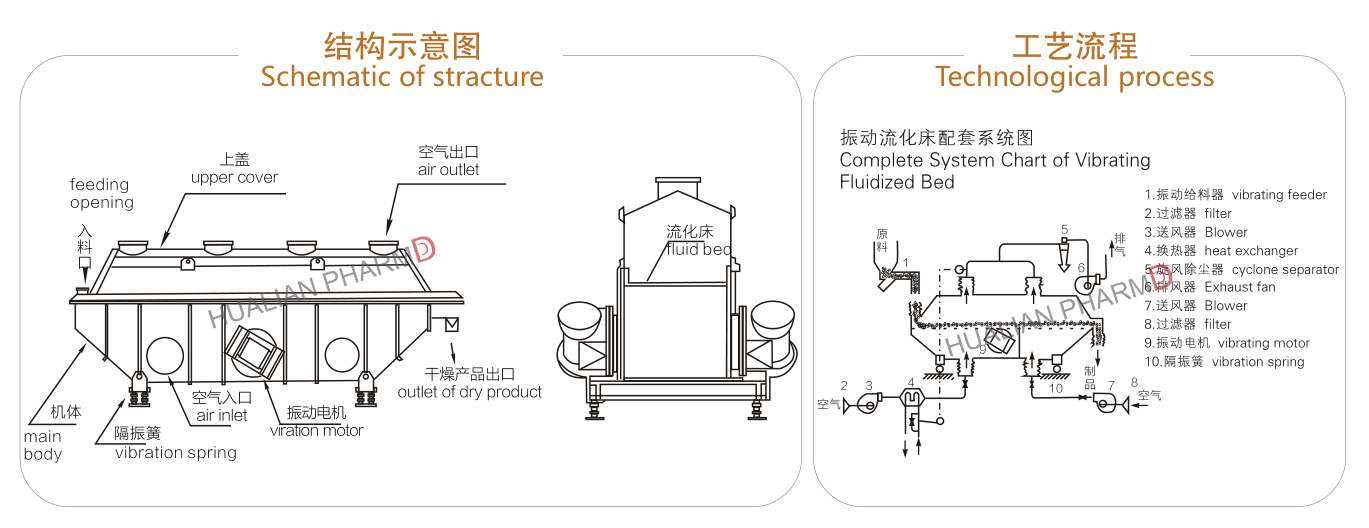

Schematic of installation:

|