| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | 25Kg Bagging Machine |

|---|---|

| Brand Name: | Sanhe |

| Model Number: | DCS-25PV3 |

| Certification: | ISO9001:2015, CE |

| Place of Origin: | Suzhou |

| MOQ: | 1 Set |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 90 Sets Per Month |

| Delivery Time: | Negotiable |

| Packaging Details: | Wood Pallet , the size of pallet to be confirmed |

| Name: | valve bag weighing Packing Machine |

| Machine Height: | 2800 mm |

| Weighing Range: | 100-300 bags per hour |

| Warranty: | 1 Year |

| Powder: | 3 KW |

| Automatic grade: | Semi-automatic |

A. What is 25 kg electronic packing scale:

Electronic packing scale consists of weighing unit, sewing machine, conveying device, pneumatic system, dust removal system, quantitative packing control, etc. the whole weighing process is controlled by PLC and completed automatically.

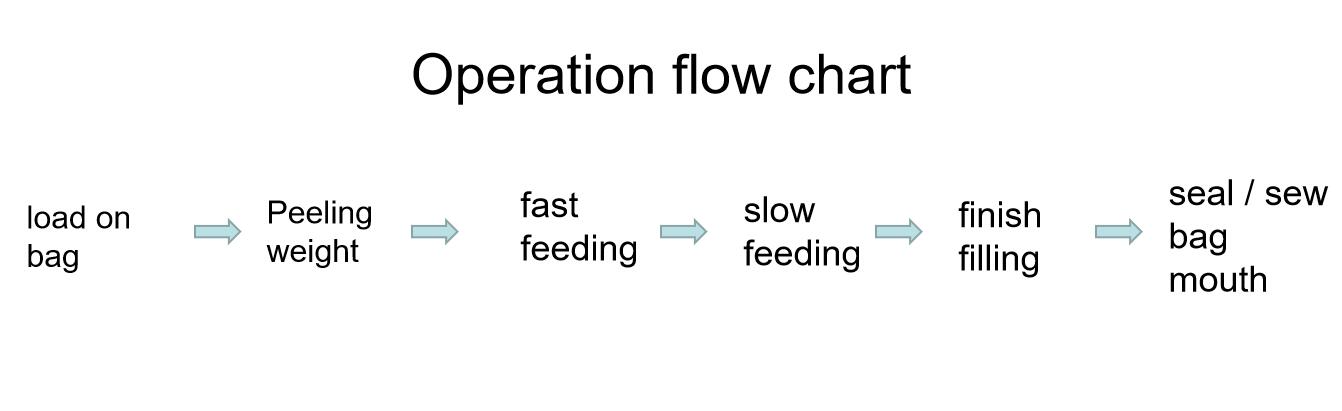

B. Working principle of 25 kg electronic packaging scale:

When the electronic packaging scale enters the automatic operation state, the weighing control system opens the feeding door to start feeding, which is a fast and slow feeding mode; when the material weight reaches the fast feeding setting value, stop the fast feeding and keep the slow feeding; when the material weight reaches the final setting value, close the feeding door to complete the dynamic weighing process;

At this time, the system checks whether the bag clamping device In the predetermined state, when the packaging bag has been clamped, the system sends a control signal to open the unloading door of the weighing bucket, and the material enters the packaging bag.

The bag clamping device will be released, and the packaging bag will fall automatically; after the packaging bag falls, the sewing bag will be carried out and transported to the next station. It operates automatically in such a cycle.

C. Generally, a packing & palletizing line includes: Electric Cabinet, sewing machine,Sewing conveyor, Bag push machine, Reshapen conveyor,Metal detector,Weight checker,Bag Rejecter,Ink-jet printer conveyer,Ink-jet printer ,Pallet magazine,Palletizing conveyor ,Robot, Wrapping Machine ,Finished palletizing conveyor.

D. According to the different styles of packaging bags, it can be divided into open mouth bag packing machine and valve type bag packing machine

Applicatioin of the Semi Automatic Gravimetric Protein Powder Filling Machine/Packaging Machine:

Especially ideal for weighing and filling various powder product, requiring big volume and high accuracy, such as highly priced medicine and Chinese herbs, biological powder, chemical powder and food additive powder etc. Range of filling and metering 1-50 kg.

DCS-25PV1(3)-SI-AL(signal scale for powder) | |

Scope of application | |

Suitable materials | Powder and thin granule |

Bag | Valve bag(automatic sealing bag) |

Feeding type | Air flow |

Alternative feeding type | Screw, impeller |

Technical parameters | |

Automatic supply bag machine | 1 |

Number of packing scale | 1 |

Feeding mouth | 1 |

One swing bag can with maximum feeding mouth number | 1 |

Weighing range(Kg) | 10-60 |

Packing speed(bag/H) | 100-300 |

Packing Accuracy | Generally (+/- )0.2%(Note: special materials shall depend on the

industrial standard) |

Advantages :

High accuracy

Easy clean out and maintence

After the machine installs you get hands on training and

documentation

The air flow feed system is capable of high production rates while

maintaining good accuracies.

Operator friendly easy set

Universal and industrial components give the machinery extra long

life

Manufactured to comply above and beyond international standards

PLC controller interface

The flexible and modular Packaging System

FAQ :

The follwing questions for us to help you find what you want ?

1, The material you want to pack and its size(μm, mm), bulk density(kg/m3)

2, Packing weight (kg/bag), capacity (t/day)

3, Detailed description of production line

Valve Bag Packer

The parameter and function table of the valve bag packer:

DCS-25PV1(1) (exhausting type) | DCS-25PV1(2) (screw type) | DCS-25PV1(3) (airflow type) | DCS-25PV1(5) (horizontal impeller) | DCS-25PV1(6) (vertiacl impeller) | |

Scope of application | |||||

Suitable materials | Powder and ultrafine powder of good Air affinity | Powder and thin granule | Powder and thin granule | Powder and ultrafine powder | Powder and ultrafine powder |

Suitable packing container | Upper and lower spiral air supply | single screw | air flow | Horizontal impeller | Vertical impeller |

Technical parameters | |||||

Weighing range(Kg) | 10-50 | 10-50 | 10-50 | 10-50 | 10-50 |

Packing speed(bag/H) | 30-180 | 30-120 | 30-200 | 30-250 | 30-250 |

Packing Accuracy | Generally (+/- )0.2%(Note: special materials shall depend on the industrial standard) | ||||

Control function | |||||

Automatic tare | ○ | ○ | ○ | ○ | ○ |

Automatic quick and slow feeding | ○ | ○ | ○ | ○ | ○ |

Automatic free fall compensation | ○ | ○ | ○ | ○ | ○ |

Automatic minus deviation | ▲ | ▲ | ▲ | × | × |

Automatic over weight alarms | ○ | ○ | ○ | ○ | ○ |

Automatic self diagnosis failure | ○ | ○ | ○ | ○ | ○ |

Manual/Automatic mode conversation | ○ | ○ | ○ | ○ | ○ |

Communication port | ▲ | ▲ | ▲ | ▲ | ▲ |

Manual adjusting the height of bag | ○ | ○ | ○ | ○ | ○ |

Suit for open and valve bag function | ▲ | ▲ | ▲ | ▲ | ▲ |

Important auxiliary function | |||||

Blow bag function in advance | ○ | ▲ | ○ | ○ | ○ |

Arch break function of hopper | ○ | ○ | ○ | ○ | ○ |

Vibration at the bottom of the bag | ○ | ○ | ○ | ○ | ○ |

Powder protection | |||||

Inflatable seal | ▲ | × | ▲ | × | × |

Negative pressure dusting(not contain duster) | ○ | ○ | ○ | ○ | ○ |

Automatic blow valve mouth | ○ | × | ○ | ▲ | ▲ |

Safety protection | |||||

Electrostatic grounding | ▲ | ▲ | ▲ | ▲ | ▲ |

| ▲ | ▲ | ▲ | ▲ | ▲ | |

Stop packing when lose power | ○ | ○ | ○ | ○ | ○ |

Emergency stop | ○ | ○ | ○ | ○ | ○ |

Ex-proof | ▲ | ▲ | ▲ | ▲ | ▲ |

Mark: “○”is standard function;“▲”is choose function ;“×”is not has function | |||||

main features:

*valve bag packing for Powder and ultrafine powder.

*Can be twin-type packer

*Can made into semi-packing and palletizing line with conveyors, sewing machine, heat sealer, fall bag conveyor, reshaping conveyor, weight checker, reject conveyor, pallet magazine, stacker.

|