| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Vacuum Brazed Diamond Tools |

|---|---|

| Place of Origin: | Shanghai, China (Mainland) |

| Brand Name: | SEB Tools |

| Model Number: | SEB-VB1027 |

| Supply Ability: | 100000 Piece/Pieces per Month |

| Packaging Details: | Regular export carton |

| MOQ: | 100 Piece/Pieces |

| Price: | $20.00 - $30.00 / Pieces |

| Product Name: | 12" ductile iron diamond blade for metal cutting |

| Application: | Concrete, Pavers, Bricks, Iron, Wood,etc |

| Material: | High Grade Diamond |

| Usage: | Demolition crews,Professional Contractor,Rescue team,urban search |

| Process: | Vacuum brazing technology |

| Advantage: | Cut twice as fast as an abrasive blade and last up to 100 times longer |

| Package: | White box,color box,blister card |

| Machine: | Angle grinder,power saw |

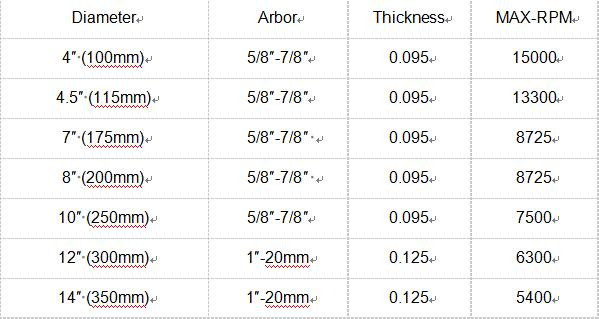

| Arrbor: | 5/8",7/8",1",20mm |

| Feature: | Vacuum Brazed Segemnt, Dry/Wet Use |

| Type: | SAW BLADE |

| Blade Material: | ALLOY STEEL |

| Finishing: | White |

| Size: | 4",4.5",5",7",9",12",14",16" |

| Port: | Shanghai |

Rescue/Demolition Saw Blades are designed for Rescue situations. Our Rescue Saw Blades can cut through a wide variety of materials. The rescue saw diamond blade is constructed from the highest quality diamonds available.Diamonds are individually placed on every segment of the rescue saw blade to prevent bunching. Rescue Saw blades are manufactured using a vacuum brazed technology. This allows the Rescue Blade to cut twice as fast as an abrasive blade and last up to 100 times longer.

Rescue Saw Blades are used in emergency situations by fire departments and rescue units throughout the world. Rescue saw blades cut through materials such as metal, chains, locks, iron fencing, re-bar, steel, pipe, ductile iron, cast iron, copper, concrete, masonry, stone, stucco, wood, HDPE, PVC, plastic, metal, roofing, steel studs, and more.

· In-line Cooling Port Design with more cooling ports to enable faster, cooler high speed diamond cutting performance in any material

· Lasts up to 100 times longer than standard rotary saw blades

· Advanced vacuum brazing process creates more exposed diamond cutting surface for longer life cutting any material

· Available in 4",4.5",7",8",9",10",12", 14" and 16" sizes

· Exclusive bi-directional cutting capability

· Cut any material, wet or dry, without changing blades

An Advanced Vacuum Brazing Process permanently fuses the cutting diamonds to the substrate yet leaves 30% more diamond cutting surface exposed for longer blade life and faster cutting.

Vacuum Brazing uses a thinner, stronger layer of bonding alloy to permanently fuse the cutting diamonds to the substrate. This process leaves up to 30% MORE diamond cutting face and edges exposed for faster cutting plus longer cutting life than electroplating.

|