| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Corrugated Roof Sheet Making Machine |

|---|---|

| Brand Name: | Acemien |

| Model Number: | SJZ80/156 |

| Certification: | CE ISO |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | Negotiation |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 300sets/year |

| Delivery Time: | 45 working days |

| Packaging Details: | standard package or film |

| Name: | Plastic recycling building machine |

| Capacity: | 250-400kg/hour |

| Thickness: | 1.5-3mm |

| Workshop: | 25*5*3.5M |

| Power: | 75kw |

| Motor: | Siemens |

| Automatic Grade: | Automatic |

| Warrnaty: | 13 month |

| Application: | Board, tile ,sheet |

| Width: | 840/1050mm |

Recycling Machine Corrugated roof sheet Building Material Making Machinery

Application:

Roof tile and resin tile can be high-grade plants, steel factories, warehouses, farm market, market access, sheds and other high-end roofing materials. Especially in corrosive chemical plants, smelters, ceramic plants, soy sauce factory, chemical plants, printing and dyeing plant, organic solvent factory, acid, alkali and other corrosive plant.

3 layer Heat Insulated UPVC Roof Sheet is manufactured based on 3 layer co-extrusion technology by one-time processing. It is an ideal building material for construction projects with heat insulation requirement. The following is a list of the distinct features of each layer material.

First layer:weather resistant resin is selected as the top layer material to block the solar ultraviolet radiation and reduce the coefficient of heat conductivity. It provides our UPVC roofing material with great durability and chemical corrosion resistance;

Second layer:the middle layer is a special foam structure with heat and sound insulation performances.

Third layer:the bottom layer of our heat insulated UPVC roof sheet adopts modified PVC material to offer optimum strength and rigidity.

Machine configuration:

| No. | Machine | Qty. | |

| 1 | Screw loader for extruder | 1set | Corrugated tile extrusion line Ridge tile forming machine |

| 2 | Conical twin-screw extruder(PVC) | 1set | |

| 3 | Vacuum loader and drying hopper | 1set | |

| 4 | Single screw extruder(ASA) | 1set | |

| 5 | Extrusion mould and distributor | 1set | |

| 1set | |||

| 7 | Temperature controller | 1set | |

| 8 | Corrugated-tile forming machine | 1set | |

| 9 | Cutter | 1set | |

| 10 | Stacker | 1set | |

| 11 | Ridge tile Oven | 1set | |

| 12 | Ridge tile Forming machine and ridge tile mould | 4set | |

| 13 | Screw loader for Mixer | 1set | Auxiliary equipment |

| 14 | Mixer unit | 1set | |

| 15 | Crusher | 1set | |

| 16 | Pulverizer | 1set |

| Raw material & formulation | PVC resin, Caco3, lubricant,stabilizing agent, pigment, anti-ultraviolet agent etc. |

| Central height: | 1000mm |

| Max. Haul-off speed: | 0.3-4m/min |

| Operation direction | From right to left (face to the operation panel) |

| Machine color | Blue or as per your request |

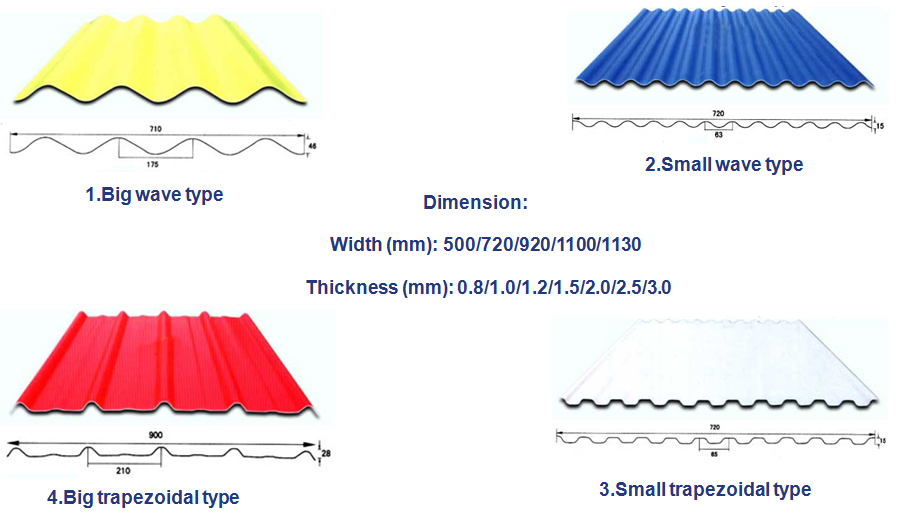

| Description final product & Output capacity | Single layers UPVC Roofing tile; Width:880 or 1050mm,Thickness: 2~4.0mm; Wave distance:180mm; Wave height:30mm; Output:200-350kg/h(Depending on CaCO3 proportion) |

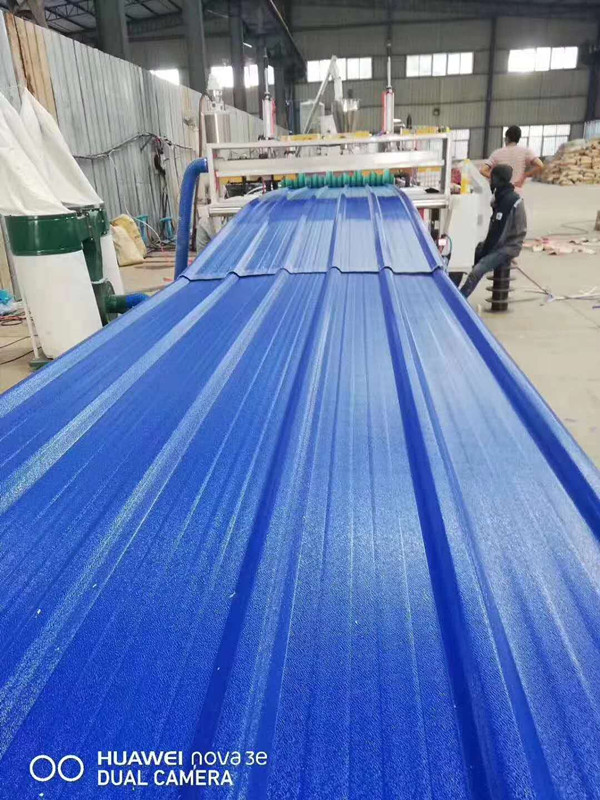

Our factory and workshop

|