| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Aluminum End Mill |

|---|---|

| Brand Name: | SUPAL |

| Place of Origin: | Changzhou,Jiangsu,China |

| MOQ: | 5PCS |

| Payment Terms: | T/T |

| Supply Ability: | 10000000PCS |

| Delivery Time: | 7-15Days |

| Packaging Details: | 1.One piece in a platic pipe, 10 pieces per group. 2.Use the air bubble paper to encase the plastic pipe. 3.Put the goods encased with air bubble paper in the carton. 4.Other packing will be accept according to your needs. |

| Product name: | Balll Nose End Mill |

| Flutes: | 2 |

| Coating: | Uncoated |

| HRC: | 45-55 |

| Suitable for: | aluminum, copper, aluminum alloy, aviation aluminum, magnesium alloy, zinc alloy, etc. |

| Applicable machine: | CNC machining center, engraving machine, high-speed machine, etc. |

| Price: | To be negotiated |

| Model Number: | OEM |

| Company Info. |

| Supal (Changzhou) Precision Tools Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Tungsten steel base material is strong and durable

Use high quality 0.2u-0.6u ultrafine particle tungsten steel bar

Strong wear resistance High toughness High hardness

Grinding process

Unique chip flute prevents chipping

Wide processing range, saving processing costs

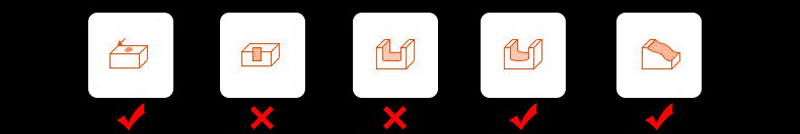

Face machining Side machining Slot machining U groove machining Surface machining

01Front angle

Large cor diameter

Adopting the suitable design of the front angle, the cutting edge

strength and sharpness are taken into account. At the same time,

the large core diameter is used to enhance the tool rigidity and

make the cutting and chip removal stable.

02 Edge belt

Double edge belt design

Design of 35 °helical angle with double blade to reduce product

burr when milling cutter is more wear-resistant

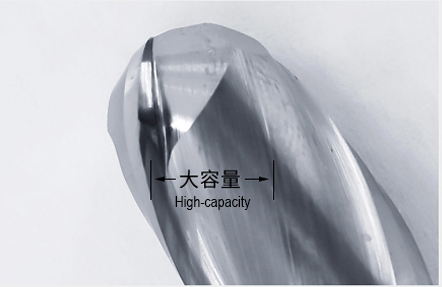

03 Chip removal

Big chip space

Large capacity chip discharge has strong cutting, discharge chip

smooth, can achieve high efficiency processing.

04 Passivated

Passivating deal with

The edge is passivated, magnifying 200 times without slight defect,

processing is not easy to have burrs, not easy to crack; the edge

is not passivated, the edge is easy to crack, collapse

phenomenon.the edge isn't flat.

05 Chamfer

Chamfer easy to operate

Handle chamfering layout is easier to fit.

| Number | Model | R radius | Blade diameter D1 | Shank diameter D | Blade number T | Blade length L1 | Total length L |

|---|---|---|---|---|---|---|---|

| 1 | R0.5X4DX2TX50L | 0.5 | 1 | 4 | 2 | 2 | 50 |

| 2 | R0.75X4DX2TX50L | 0.75 | 1.5 | 4 | 2 | 3 | 50 |

| 3 | R1.0X4DX2TX50L | 1 | 2 | 4 | 2 | 4 | 50 |

| 4 | R1.25X4DX2TX50L | 1.25 | 2.5 | 4 | 2 | 5 | 50 |

| 5 | R1.5X4DX2TX50L | 1.5 | 3 | 4 | 2 | 6 | 50 |

| 6 | R1.75X4DX2TX50L | 1.75 | 3.5 | 4 | 2 | 7 | 50 |

| 7 | R2.0X4DX2TX50L | 2 | 4 | 4 | 2 | 8 | 50 |

| 8 | R2.5X6DX2TX50L | 2.5 | 5 | 6 | 2 | 10 | 50 |

| 9 | R3.0X6DX2TX50L | 3 | 6 | 6 | 2 | 12 | 50 |

| 10 | R4.0X8DX2TX60L | 4 | 8 | 8 | 2 | 16 | 60 |

| 11 | R5.0X10DX2TX75L | 5 | 10 | 10 | 2 | 20 | 75 |

| 12 | R6.0X12DX2TX75L | 6 | 12 | 12 | 2 | 24 | 75 |

| 13 | R8.0X16DX2TX100L | 8 | 16 | 16 | 2 | 30 | 100 |

Conventional cutting parameters

| Cutting material | Aluminum | Aluminum | Aluminum alloy Si,Mg-Si | Aluminum alloy Si,Mg-Si | Aluminum alloy Mg | Aluminum alloy Mg | Aluminum alloyZn-Mg | Aluminum alloyZn-Mg | Aluminum alloys Casting | Aluminum alloys Casting | CopperAlloys | CopperAlloys |

| Edge diameter | rotation rate | feed | rotation rate | feed | rotation rate | feed | frotation rate | feed | rotation rate | feed | rotation rate | feed |

| 3 | 32000 | 800 | 5300 | 200 | 1300 | 400 | 27000 | 400 | 16000 | 500 | 7900 | 200 |

| 5 | 19200 | 1000 | 3200 | 250 | 8000 | 500 | 16000 | 500 | 9600 | 600 | 4700 | 240 |

| 6 | 16000 | 1000 | 2650 | 250 | 6500 | 500 | 13500 | 500 | 8000 | 600 | 3900 | 240 |

| 8 | 12000 | 1000 | 2000 | 300 | 5000 | 600 | 10000 | 600 | 6000 | 700 | 2900 | 240 |

| 10 | 9600 | 1200 | 1600 | 300 | 4000 | 600 | 8000 | 600 | 4800 | 700 | 2300 | 240 |

| 12 | 8000 | 1200 | 1300 | 350 | 3300 | 700 | 6600 | 700 | 4000 | 800 | 1900 | 280 |

| 16 | 6000 | 1200 | 1000 | 350 | 2500 | 700 | 5000 | 700 | 3000 | 800 | 1400 | 280 |

| 20 | 4800 | 1200 | 800 | 350 | 2000 | 700 | 4000 | 700 | 2400 | 800 | 1100 | 280 |

| Side Milling ap | 1.5D | 1.5D | 1.5D | 1.5D | 1.5D | 1.5D | 1.5D | 1.5D | 1.5D | 1.5D | 1.5D | 1.5D |

| Side Milling ae | 0.2D | 0.2D | 0.2D | 0.2D | 0.2D | 0.2D | 0.2D | 0.2D | 0.2D | 0.2D | 0.2D | 0.2D |

| Grooving ap | 1.0D | 1.0D | 1.0D | 1.0D | 1.0D | 1.0D | 1.0D | 1.0D | 1.0D | 1.0D | 0.5D | 0.5D |

| D.Dia.of mill Groocing Side milling | 1.Use in wet condition 2.When using low speed machines,use maximum speed and adjust the feed rate. 3.adjust milling cindition when unusual vibration.different sound occur by cutting. |

|