| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Industrial Ultrasonic Cleaner |

|---|---|

| Brand Name: | Skymen |

| Model Number: | JP-2060G |

| Certification: | RoHS, CE, FCC, SGS |

| Place of Origin: | Shenzhen, China |

| MOQ: | 1 |

| Price: | Negotiation |

| Payment Terms: | T/T |

| Supply Ability: | 800 pcs per month |

| Delivery Time: | In Stock |

| Packaging Details: | Wooden case |

| Model: | JP-2060G |

| First tank volume: | 99L |

| First tank size: | 500X450X400mm |

| Transducers: | 60pcs; 30pcs of every tank |

| Ultrasonic Power: | 3000W; 1500W of every tank |

| Heating Power: | 6000W; 3000W of every tank |

| Filtration Cycle System: | Connected with 1st tank |

| Frequency: | 28/40KHz |

| Company Info. |

| Skymen Technology Corporation Limited |

| Verified Supplier |

| View Contact Details |

| Product List |

SUS 316 Material Double tanks Industrial Ultrasonic Cleaner

28/40KHz For Punches, Ejector Pins 100L

Specification

| Model | JP-2060G |

| 1st Tank Volume | 99L |

| 2nd Tank Volume | 99L |

| First tank size | 500X450X400mm |

| Second tank size | 500X450X400mm |

| Transducers | 60pcs 50W of every transducer, 30pcs of every tank |

| Ultrasonic Power | 3000W 1500W of every tank |

| Heating Power | 6000W 3000W of evey tank |

| Frenquency | 28KHz/40KHz |

| Filtration Cycle System | 1 set |

| Generator | 2 set |

| Unit size | 1500*1150*850mm |

| Packing size | 1560*1210*970mm |

| Timer | 0~99 minutes adjustable |

| Heater | Room temperature~99℃ adjustable |

| Material | SUS 304 default, can be SUS 316 |

| Power Supply | AC 220V 3 phase ; AC 380V 3 phase |

| N.W. | 250KG |

| G.W. | 280KG Wrapped by film in wooden case |

| Lead time | 18 working days |

| Warranty | 1 year warranty period, technique support all time |

| Certificates | CE, RoHS, FCC, SGS |

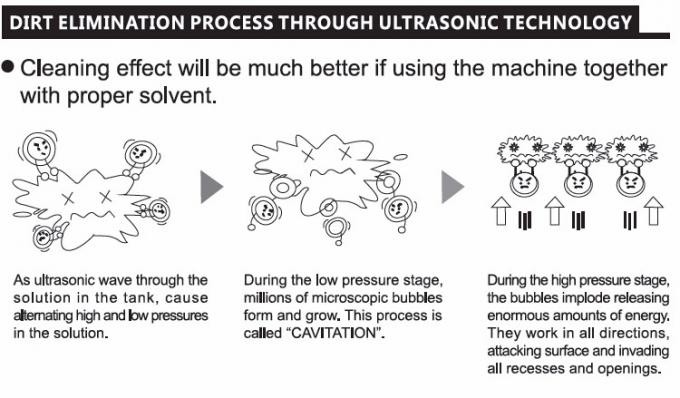

| Advantage | Filter the dirty water; keep the water clear in tank; lower the frequency of changing water |

Images:

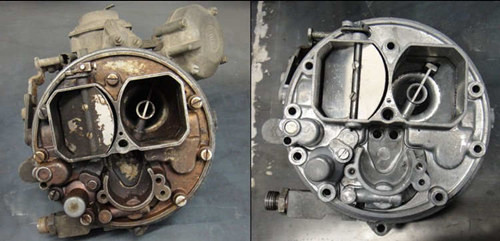

Clean effect:

Same series with different size:

| Model | Size of every tank | Tank Volume | Ultrasonic Power | Heating Power | Transducer |

| L*W*H (mm) | (L) | (W) | (W) | (pcs) | |

| JP-2024G | 500X300X250 | 38L*2 | 600W*2 | 1500W*2 | 24pcs |

| JP-2036G | 500X350X300 | 53L*2 | 900W*2 | 1500W*2 | 36pcs |

| JP-2048G | 550X400X350 | 77L*2 | 1200W*2 | 3000W*2 | 48pcs |

| JP-2060G | 550X450X400 | 99L*2 | 1500W*2 | 3000W*2 | 60pcs |

| JP-2072G | 600X500X450 | 135L*2 | 1800W*2 | 4500W*2 | 72pcs |

| JP-2096G | 700X500X500 | 175L*2 | 2400W*2 | 6000W*2 | 96pcs |

| JP-2120G | 800X600X550 | 264L*2 | 3000W*2 | 6000W*2 | 120pcs |

| JP-2144G | 1000X600X600 | 360L*2 | 3600W*2 | 9000W*2 | 144pcs |

| JP-2216G | 1000X900X600 | 540L*2 | 5400W*2 | 18000W*2 | 216pcs |

| JP-2288G | 12000*1000*800 | 960L*2 | 7200W*2 | 27000W*2 | 228pcs |

Suggested Ultrasonic Cleaning Procedure

In all cases manufacturers’ instructions should be followed when using an ultrasonic cleaning process. These are representative steps.

Fill the ultrasonic cleaning tank with an approved medical instrument cleaning solution such as CLN-LR012 available from Tovatech following dilution instructions provided. Turn the cleaner on to start the degassing process. This step removes entrained air in new solutions that interferes with the efficiency of cavitation and takes approximately 10 minutes.

In the meantime:

Segregate instruments by alloy or composition to avoid potential damage (Chromium plated instruments should not be cleaned ultrasonically)

Instruments with movable parts should be disassembled to facilitate cleaning

Place the instruments the ultrasonic cleaner’s mesh basket, taking

care that they do not come in contact with each other

Cannulated or lumened instruments should be positioned to insure

interiors are wetted with the cleaning solution. In some instances

placing them on an angle will facilitate this

Set the control panel per manufacturers’ instructions and start the cleaning process

At the end of the cycle, remove the instruments from the ultrasonic cleaning bath and thoroughly rinse them to remove all traces of the cleaning solution. Deionized water rinses will avoid spotting. If the instruments are not to be immediately disinfected and sterilized be certain that they are thoroughly dried and protected. Part reassembly can occur after sterilization.

Procedures should be in place to guide the replacement of used ultrasonic cleaning solutions. In some instances it is recommended that solution be drained and tanks thoroughly cleaned and dried after each ultrasonic cleaning cycle. Most solutions available today are biodegradable, which facilitates disposal but local authorities should be consulted on proper practices.

History:

Skymen Cleaning Equipment Shenzhen Co., Ltd., was founded in

2007,which follows the brand development strategy of “based in

Shenzhen, radiating throughout the country, expanding overseas”.

Skymen also owns a professional R&D team to keep the pace with

international ultrasonic technology. A passionate and young sales

team sell to the world through different channels.

|