| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Vertical Slurry Pump |

|---|---|

| Brand Name: | Chengdu Yongyi |

| Model Number: | ZJL |

| Certification: | ISO9001 |

| Place of Origin: | Sichuan, China |

| MOQ: | 1 set |

| Price: | USD 500-5000/set |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Paypal |

| Supply Ability: | 300 sets per month |

| Delivery Time: | 25 working days after receiveing advance payment |

| Packaging Details: | Free Fumigation Export Wooden Box |

| Theory: | Centrifugal Pump |

| Max Flow: | 364m 3/ h |

| Max Head: | 58m |

| Material: | Corrosive Resistance Material |

| Fuel: | Electric |

| Color: | Customized |

| Voltage: | 380V/660V/1140V |

| Structure: | Single-stage Pump |

| Product name: | Submersible Sewage Sump Mud Pump Submerged Slurry Pump |

Submerisble Vertical Industrial Slurry Pumps Cantilever Type For Mining

Main Usage

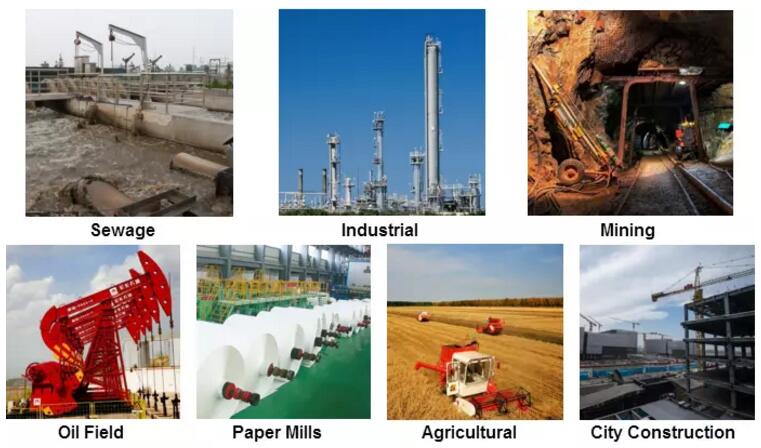

Durable slurry pump is suited for handling abrasive or corrosive, dense slurry with large particle size, vertical submersible slurry pump are mainly applicable to transport abrasive, coarse particle, high concentration slurry. They are widely used in metallurgy, mining, coal, electric power, building materials, environmental protection and other departments.

Parameter Range

| Name | ZJL-series Vertical Slurry Pump |

| Head | 4 ~ 60 m |

| Capacity | 6 ~ 364m³/h |

| Discharge Size | 40mm~200mm |

| Inlet Size | 50mm~250mm |

| Maximal Efficiency | 70% |

| NPSH | 1.4m~3.5m |

| Allowable Max Motor Power | 315 kw |

| Diameter | 200mm~470mm |

Product Features

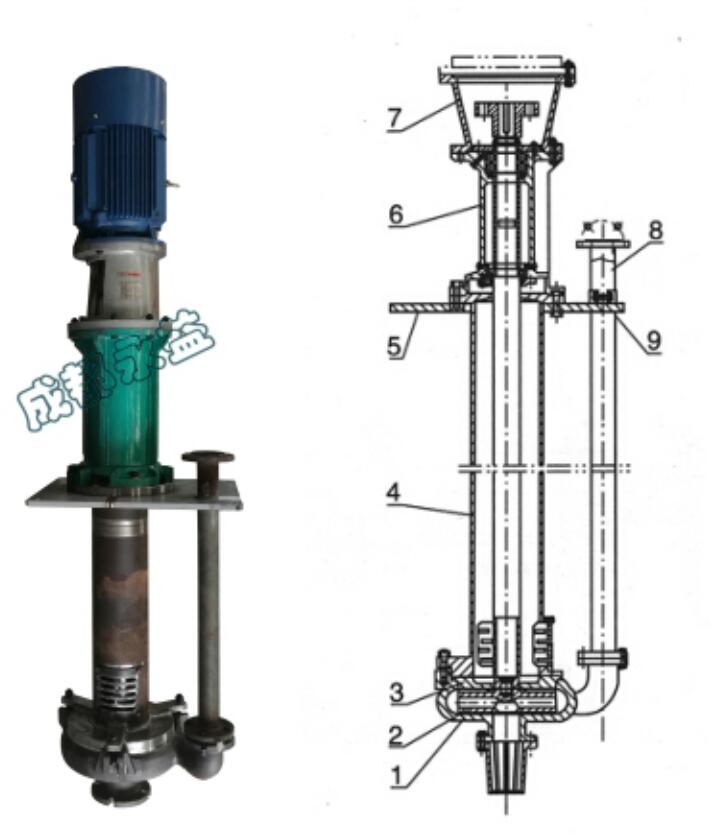

CANTILEVERED SHAFT

The standard ZJL pumps feature a cantilevered shaft which is up to 2400mm long. The cantilevered shaft means that there is no shaft sealing requirement and the drive end bearings do not come into contact with any pumped product. This reduces the risk of bearing failure and extends the wear life of the pumps.

HEAVY DUTY WET END

Wet end components are manufactured from high quality 27% chrome white iron or rubber coated steel for exceptional wear resistance and service life with minimal corrosion. The heavy duty design can pump high density and abraisive slurries and the large passages of the impeller allows the transfer of large particles without blockages in a wide range of mining, processing and heavy industrial applications. Wet end stub shaft options are available to suit severe duty applications.

COLUMN AND DISCHARGE PIPES

Column and discharge pipes are available in a range of materials to suit the requirements of operators. Standard options include mild steel and rubber lined mild steel. Composite options are available.

VERSATILE DRIVE OPTIONS

Pumps can be directly driven using electric motors or belt driven with either set speed or variable speed operation.

REMOVABLE STRAINERS

Pumps feature rubber or cast iron upper strainers and cast iron lower strainers to prevent blockages. The strainers are easily removed for servicing or replacement.

Material

Description | Standard Material | Material Options |

Shaft | 4140 Mild Steel | Available on Request |

Bearing Housing | Cast Iron | |

Column | Mild Steel | |

Upper Strainer | Rubber | Cast Iron |

Lower Strainer | Cast Iron | |

Back Liner | 27% Chrome White Iron | |

Pump Casing | 27% Chrome White Iron | Rubber Lined White Iron |

Impeller | 27% Chrome White Iron | Rubber |

Discharge Pipe | Mild Steel | Rubber Lined Mild Steel/ Composite |

Adaptor Plate | Mild Steel |

Structure

| 1 | Volute casing | 2 | support | 3 | Motor base |

| 4 | Impeller | 5 | Left support plate | 6 | Discharge pipe |

| 7 | Rear liner plate | 8 | Bearing body | 9 | Right support plate |

Product and Details

Quality Control

We test the casing chemcial content by spectrometer for each oven. The materiral test certificate for main parts could be provided.

We made the hydralic static pressure test for each pump. The hydralic test report could be provided.

For slurry pump, we just make the staic balance test; For each API610&Chemical pump, we will make the dynamic balance test. The balance test report could be provided.

We will make performance test for each pump before delivery, we will test capacity, head, pump speed, efficiency, NPSHr, Vibration pump noise and bearing tempreture. The report could be provided.

Certifications

|