| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Chemical Process Pump |

|---|---|

| Brand Name: | Chengdu Yongyi |

| Model Number: | CZ |

| Place of Origin: | Sichuan,China |

| MOQ: | 1 Set |

| Price: | USD499-6000/set |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Paypal |

| Supply Ability: | 300 set/month |

| Delivery Time: | 25 working days after receiveing advance payment |

| Packaging Details: | Quality Export Wooden Box |

| Certification: | ISO9001 |

| Pressure: | 2.5MPa |

| Flow: | 4~2000 m3/h |

| Head: | 2~160 m |

| Feature: | High Efficiency |

| KW: | Horizontal Chemical Process Pump |

| Motor: | Non-exproof/exproof pump |

| OEM: | Yes |

Horizontal Split Volute Chemical Process Pump , Single Stage

Chemical Transfer Pumps

Pump Description

(1)Suitable to transfer various kinds of chemical liquid

Pumps used in the chemical industry are not only transfer liquid

slurry, but also mediums contain solid content. In a certain

chemical unit operation, pump flow and head should satisfy

customer's requirements, and should be stable.

(2) Anti-corrosion

Chemical pump delivered medium, including raw materials, reaction

intermediated are always corrosive medium. This requires pump

selection of materials properly and reasonably, ensuring the pump

security, stability, long life operation.

(3)Stable operation

Chemical pump reliable operation includes two meanings: one is long

period running without fault; another is in the operation the

various parameters is smooth. YCZ-series pump center line and the

pump foot support have the largest anti-pipe load capacity. The

double volute design for the large flow and high lift pump flow

path reduce the radial force and the dynamic deflection. In this

way, the pump runs smoothly in a long period.

Product Picture

Technical Data

Model | Rated Speed n=2900r/min | Rated Speedn=1450r/min | |||||||||||||

Impeller | Capacity Q (m3/h) | Head H(m) | Relative Density ρ=1.00 | Relative Density ρ=1.84 | Impeller | Capacity (m3/h) | Head H(m) | Relative Density ρ=1.00 | Relative Density ρ=1.84 | ||||||

Motor Power and Model | Motor Power and Model | ||||||||||||||

Kw | Kw | Kw | Kw | ||||||||||||

YCZ80/250 | D | 150 | 55 | 37 | 200L2-2 | 75 | 280S-2 | E | 70 | 11 | 5.5 | 132S-4 | 7.5 | 132M-4 | |

X | 140 | 50 | 30 | 200L1-2 | |||||||||||

E | 130 | 47 | 55 | 250M-2 | |||||||||||

YCZ80/315 | A | 200 | 130 | 110 | 315S-2 | 185 | 315L-2 | A | 100 | 32 | 15 | 160L-4 | 30 | 200L-4 | |

B | 190 | 125 | B | 95 | 30 | ||||||||||

M | 180 | 120 | 90 | 280M-2 | 160 | 315L1-2 | C | 85 | 24 | 11 | 160M-4 | 18.5 | 180M-4 | ||

N | 170 | 110 | 75 | 280S-2 | D | 70 | 18 | 7.5 | 132M-4 | 15 | 160L-4 | ||||

C | 160 | 100 | 132 | 315M-2 | |||||||||||

X | 150 | 90 | 110 | 315S-2 | |||||||||||

D | 140 | 80 | 55 | 250M-2 | 90 | 280M-2 | |||||||||

YCZ80/400 | A | 105 | 52 | 30 | 200L-4 | 55 | 250M-4 | ||||||||

B | 100 | 50 | 55 | 250M-4 | |||||||||||

C | 90 | 44 | 45 | 225M-4 | |||||||||||

D | 80 | 38 | 18.5 | 180M-4 | 37 | 225S-4 | |||||||||

E | 75 | 30 | 15 | 160L-4 | 30 | 200L-4 | |||||||||

YCZ100/200 | A | 230 | 45 | 45 | 225M-2 | 75 | 280S-2 | A | 115 | 11 | 7.5 | 132M-4 | 11 | 160M-4 | |

B | 210 | 40 | 37 | 200L2-2 | 55 | 250M-2 | B | 100 | 10 | 5.5 | 132S-4 | ||||

C | 180 | 32 | 22 | 180M-2 | 45 | 225M-2 | C | 90 | 8 | 4 | 112M-4 | 7.5 | 132M-4 | ||

D | 150 | 25 | 37 | 200L2-2 | D | 80 | 6 | 3 | 100L2-4 | 5.5 | 132S-4 | ||||

YCZ100/250 | A | 280 | 75 | 90 | 280M-2 | 160 | 315L1-2 | A | 130 | 20 | 15 | 160L-4 | 22 | 180L-4 | |

B | 260 | 70 | 75 | 280S-2 | 132 | 315M-2 | B | 125 | 16 | 11 | 160M-4 | 18.5 | 180M-4 | ||

M | 240 | 65 | 75 | 280S-2 | 110 | 315S-2 | C | 120 | 14 | 15 | 160L-4 | ||||

C | 220 | 60 | 55 | 250M-2 | 110 | 315S-2 | D | 100 | 10 | 7.5 | 132M-4 | 11 | 160M-4 | ||

N | 200 | 52 | 45 | 225M-2 | 90 | 280M-2 | |||||||||

D | 175 | 45 | 37 | 200L2-2 | 75 | 280S-2 | |||||||||

YCZ100/315 | A | 270 | 135 | 160 | 315L1-2 | A | 130 | 32 | 22 | 180L-4 | 37 | 225S-4 | |||

B | 260 | 128 | 132 | 315M-2 | B | 120 | 30 | 18.5 | 180M-4 | 30 | 200L-4 | ||||

M | 250 | 120 | C | 100 | 26 | 15 | 160L-4 | ||||||||

N | 230 | 112 | 110 | 315S-2 | 185 | 315L-2 | D | 90 | 21 | 11 | 160M-4 | 18.5 | 180M-4 | ||

C | 220 | 105 | |||||||||||||

X | 210 | 95 | 90 | 280M-2 | 160 | 315L1-2 | |||||||||

D | 190 | 85 | 75 | 280S-2 | 132 | 315M-2 | |||||||||

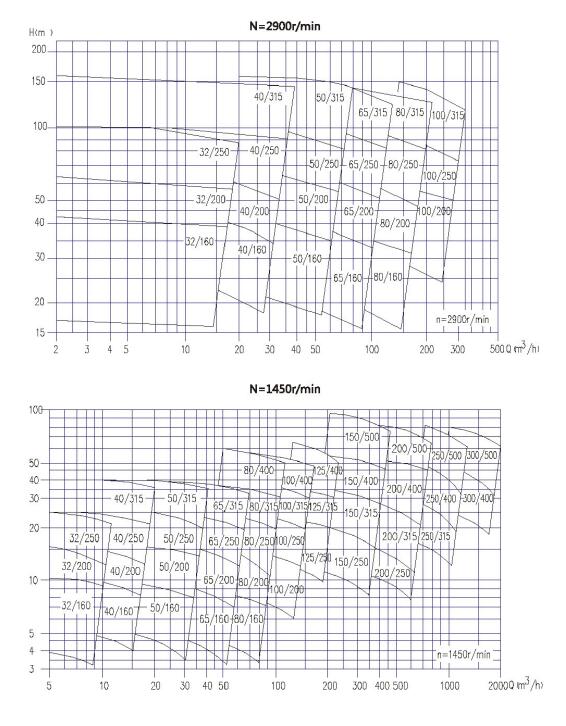

Performance Curve

Pump Performance Curve is one of the most important technical document to show the pump performance. At any point, the curve can show the capacity, head, rpm, efficiency etc.of the pump. General speaking, the capacity and head of the pump is different if the pump pressure is different.

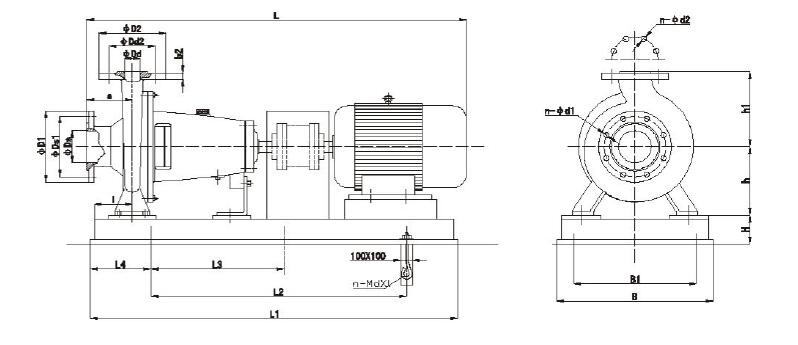

Installation Dimension

FAQ

1. Q: Are you a manufacturer or trading company?

A: We are a manufacturer established in 1995, professional

manufacturer of chemical-process pump and energy-saving mixer with

more than 20-year experience.

2. Q: What's your delivery time?

A: The batch order will be shipped within 40 working days after

receiving deposit.

3. Q: What's your warranty service policy?

A: 12 Months for all products, and some products warranty is

24months.

4. Q: What information I need to offer for quotation?

A: Medium: ____________ PH: ________

Specific Gravity: _______ Temperature: _________

Capacity/Flow: ________m3/h Head: _________m

Voltage: ____________V Frequency: _________Hz

Power:_____________KW

5. Q: What is your minimum quantity?

A: One set is also welcomed to us.

|