| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Plastic Sheet Extrusion Line |

|---|---|

| Brand Name: | ZHMC Machiney |

| Model Number: | PP-PE |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 5 sets per month |

| Delivery Time: | 90 days |

| Packaging Details: | Wooden package |

| Plastic Processed: | PP PS PE |

| Power: | 100KW |

| Weight: | 8 Tons |

| Sheet width: | 300-2500mm |

| Material: | PVC PP PE |

| Working condition: | 380 V |

PVC plate extrusion line PVC Tile wood sheet extruder production rubber sheet making machine

PVC plate extrusion line PVC Tile wood sheet extruder Usage

This machine is used to produce PP/PS plastic sheet rolls for thermoforming machine and vacuum forming machine, which is used for making disposable plastic water drinking cups, juice cups, tea cups, milk cups, ice cream cups, yogurt cups, jelly cups, bowls, food containers, lids, flowerpot, seeding trays, etc varous packages.

Extrusion Process

1 . Plastic pellets are fed into the barrel of the extruder and conveyed by the screw, the heaters which are outside of the barrel of the extruder as well as the friction from the rotation of the screw melt the plastic pellets into a sheet mold and then placed on a three-roll calender.

2 . The produced sheet goes through the bottom and middle roll,wrapping around back of the middle roll and then back to the top roll or other methods as shown in sheet calender picture, these rolls are helpful to take the heat out of the sheet.

3 . After the sheet comes off the roll,it moves down the conveyor to the end of sheet line where the edge trimmer cuts the sheet to width as well as a sheet shear cutter to length.

Main Technical Parameter

| Target material | PP/HIPS/GPPS |

| Efficient width of sheet | 680mm(adjustable) |

| Thickness of sheet | 0.3~2.0mm |

| Tolerance of thickness | ±0.01mm |

| Main Motor Power | 45KW |

| Screw Dia. | 110mm |

| Screw L/D | 33:1 |

| T-die Width | 800mm |

| Size of Calander Roller | Φ350×780mm |

| Maximum output | 150kg/hr |

| Power Voltage | 380V/50HZ, 3P, 4Wire |

| Approx. Machine Dimension | ~12500×1850×2200mm |

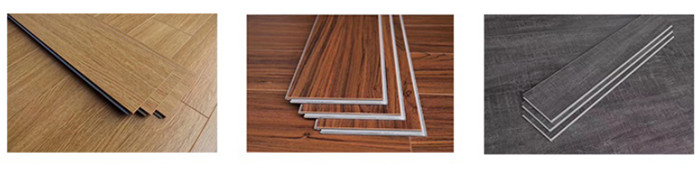

Product Display

|