| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Solid Carbide End Mills |

|---|---|

| Brand Name: | SHIELD |

| Model Number: | PM-6E |

| Certification: | ISO9001:2008 |

| Place of Origin: | Hunan China |

| MOQ: | 10pcs |

| Price: | Negotiable |

| Payment Terms: | L/C D/A D/P T/T Western Union |

| Supply Ability: | 200,000 per month |

| Delivery Time: | 5-35 workdays after received the payment |

| Packaging Details: | Plastic box packed for each pieces, carton boxes outside |

| Product name: | PM-6E High-performance general milling PM series |

| Material: | WC: 0.6μm grain size 12.0% Co |

| Type: | 6-flute corner protection flattened end mills with straight shank |

| Diameter: | 6-20mm |

| Overlength: | 60-100mm |

| Flute: | 6-flute |

| Coating: | NaNo AlTiN |

| HRC: | 40/50/55 |

| Suitable for: | Carbon steel, alloy steel, hardened steel, stainless steel , cast iron, nodular cast iron, titanium alloy, heat resistant alloy |

| Application: | High-rigidity , very suitable for side finish machining, high speed ,high feed rate machining applicable |

PM-6E-D6.00~D20.0 6 flute corner protection flattened end mills

| Type | Basic dimension(mm) | Number of teeth Z | |||

|---|---|---|---|---|---|

| D | d | H | L | ||

| PM-6E-D6.0 | 6.0 | 6 | 18 | 60 | 6 |

| PM-6E-D8.0 | 8.0 | 8 | 20 | 60 | 6 |

| PM-6E-D10.0 | 10.0 | 10 | 30 | 75 | 6 |

| PM-6E-D12.0 | 12.0 | 12 | 32 | 75 | 6 |

| PM-6E-D16.0 | 16.0 | 16 | 40 | 100 | 6 |

| PM-6E-D20.0 | 20.0 | 20 | 45 | 100 | 6 |

Detailed Product Description:

PM= High performance general machining

6E= 6 flute corner protection flattened with straight shank

D6.0= Tool diameter 6.0mm

Number of teeth: 6 Flutes

End tooth type of mills: 6-flute corner protection flattened end mills with straight shank

Cutting diameter tolerance: D </= 12 ( 0~-0.020mm )

D<12 (0~-0.030mm)

Coated: NaNo AITiN coating

Helical angle: 45 degree

Machining operation:

a. Side face: Flattened end mills for side machining

b. Step shoulder: Flattened end mills for shoulder machining

c. Straight slot: Flattened end mills for deep slot machining

Applicable workpiece material:

1. Very suitable for carbon steel , alloy steel, Pre-hardened steel ,hardened steel with 40HRC/50HRC/55HRC, cast iron, nodular cast iron

2. Suitable for stainless steel, Tianium alloy, heat resistant alloy

Advantage of high-performance general machining end mills

1. Optimized geometry, improves chip removal and chip forming with reduced cutting force.

2. Higher feed rates and improved metal removal rate for efficient machining, due to high stability of cutting edge and rigid tool structure.

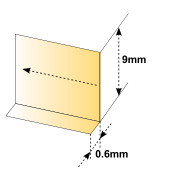

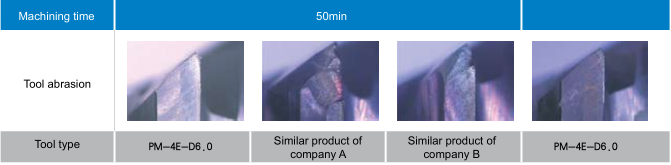

Tool diameter: Ø6.0mm

Tool type: a) PM-4E-D6.0

b) Tool from overseas manufacturer

Machine tool: Mikron UCP 1000

Cooling system: air blow

Machining operation: side milling (down milling)

Cutting parameters: Vc=100m/min

ap=9mm, ae=0.6mm

Fz=0.4mm~0.16mm

3. With excellent wear resistance and toughness, high wear resistance and breakage resistance is achieved even during high performance milling.

Tool type: PM-4E-D6.0 Radial cutting depth: ae=0.6mm

Diameter: Ø6.0mm Cutting stype: side milling( down milling)

Workpiece material: NAK80(40HRC) Cooling system: air blow

Rotating speed: 5300r/min(100m/min) Machine tool: MIKRON UCP1000

Feed speed: 1696mm/min(0.32mm/r) Tool overhang: 22mm

Axial cutting depth: ap=9mm

Machining results

Conclusion: compared with other tools manufacturer, PM series has better breakage resistance.

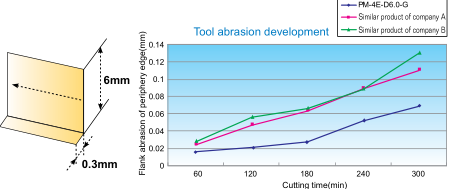

The application status of PM-4E-D6.0-G in high speed milling.

Tool type: PM-4E-D6.0-G

Diameter: Ø6.0mm

Workpiece material: NAK80(40HRC)

Rotating speed:13260r/min(250m/min)

Feed speed: 2652mm/min(0.2mm/r)

Axial cutting depth: ap=6mm

Radial cutting depth: ap=0.3mm

Cutting style: side milling( down milling)

Cooling system: air blow

Machine tool: MIKRON HSM800

Tool overhang: 22mm

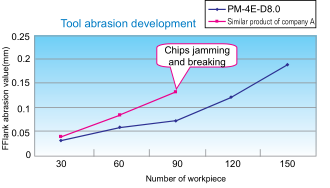

High efficiency machining alloy steel of PM-4E-D8.0.

Machine tool: MIKRON UCP1000

Tool holder: HSK63-A Workpiece material: alloy steel

Cutting speed: 100(m/min)

Feed rate per tooth: 0.04(mm/tooth)

Axial cutting depth: 8(mm)

Radial cutting width(mm): changing, Maximum at full cutting

Cooling system: Emulsified liquid

Milling style: Contour following

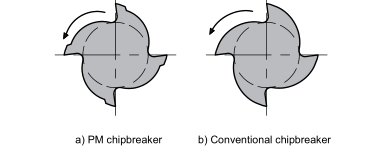

End mills series of sharp and corner protection type

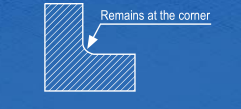

The characteristic of corner protection end mill:

1) It's suitable for bad cutting condition or hardness material machining.

2) High cutting edge strength and breakage resistance.

3) The degree of nose sharpness is reduced, the vestiage is left.

The characteristic of sharp end mill:

1) True 90 degree angle is obtained without material remaining in the corner.

2) The corner part is sharp, it is applicable in finishing or soft material machining. Especially, it is usually used in machining of non-ferrous material such as AI.

|