| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Spinner Hanger Blast Machine |

|---|---|

| Brand Name: | TAISHENG |

| Model Number: | Q376 |

| Certification: | ISO9001-2015 |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | Negotiation |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 10 sets per month |

| Delivery Time: | 15-20days |

| Packaging Details: | PE+ABF+Pallet |

| Material: | Carbon Steel |

| Max.Product: | Φ600*1200mmH |

| Qty of Wheel: | 2pcs x 7.5kw |

| Dust Collector: | Cartridge |

| Total Power: | 29kw |

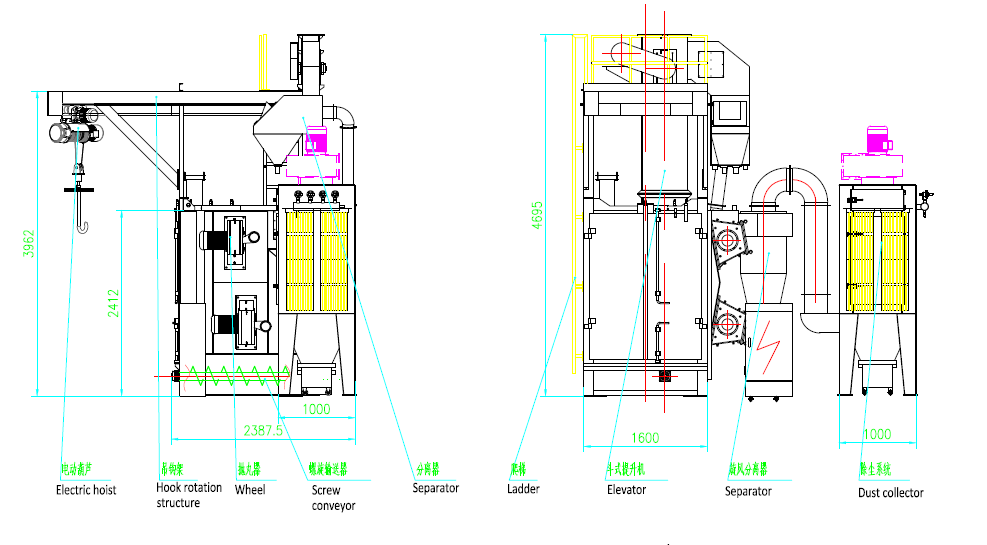

| Overall Size: | L2730mm*W5760mm* H4690mm |

Q376 Single Hook Spinner Hanger Blast Machine for Cleaning Castings Dimension Dia.600mm Height 1200mm

Quick detail

| Workpiece Description | Max part dimension | Φ600*1200mmH |

| Max part weight | <600kg | |

| Cleaning requirement | Meet standard of GB8923-88 A-B Sa2½, surface roughness Ra12.5 | |

| Time of cleaning one hook | Casting 8-15min; Forging 5-8min | |

| Noise Level | ≤85 dB | |

| Dust Emission | ≤80 mg/m³ | |

| Recommend Abrasive | Φ0.2~Φ1.0mm steel cut wire or steel shot | |

| Abrasive Initial Feed | 1.0-1.5T | |

| Machine Footprint | L2730mm*W5760mm* H4690mm | |

| Pit Foundation | Not required | |

| Compressed Air Consumption | <0.6m3/min; 0.4Mpa~0.6Mpa | |

| Power Consumption | 29kw | |

Application possibilities

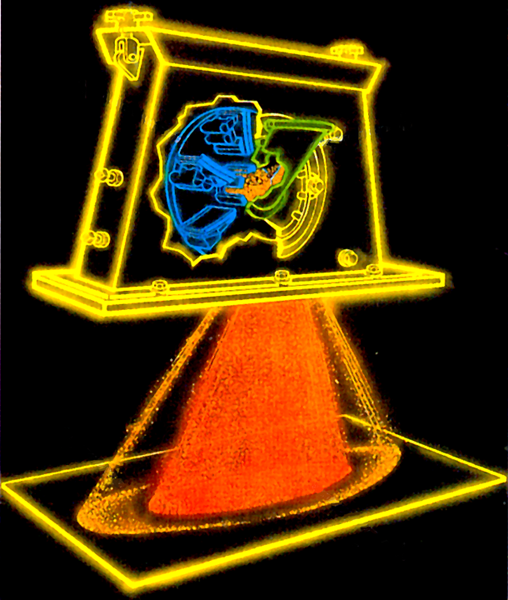

TS Spinner Hanger Machines are designed to clean a wide range of parts size and shapes. These shot blasting machines can be set up with dual swing doors, I or Y hanger and with multiple blast wheels. Parts are loaded onto a hanger and moved in, started rotating, got blasted and moved out.

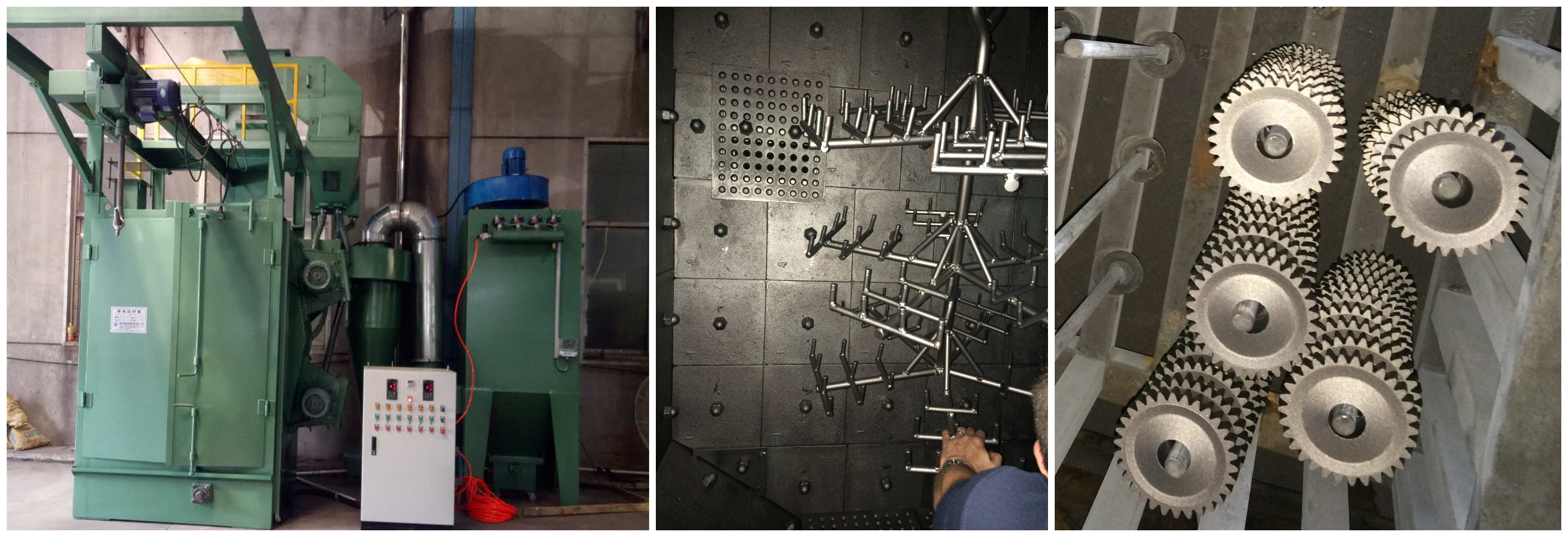

Widely used in small and medium size of stainless steel parts, castings, die castings, forgings, welding structures and heat treatment parts surface cleaning and strengthening.

Advantages of using TS Spinner Hanger Machine

Machine Introduction

It is composed by shot blasting cabinet, blasting system, electrical hanger system, rotation system, abrasive recovery system, dust removal system, electrical control system and so on.

Blast Cabinet

This machine equips with thickness 6mm wear-resistant manganese steel plate Mn13 as protective.

Blast Wheel 7.5kw x 2pcs

Hanger System

Rotation speed 2.8r/min

Motor Power 0.55kw

Moving power 0.2 kw

Moving speed 14 m/min

Lifting power 1.5 kw

Lifting speed 4 m/min

Max loading 600kg

Abrasive Recovery System 3.0kw

Catridge Dust Collector 4.0kw Filtering Area 56m2

Pulse-jet Air Clean System: The dust collector has a programmable time board to “pulse” the cartridges with a jet of compressed air between blast cycle to purge the filter.

Electrical Control System 380V/50Hz/3phase (Customize)

|