| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Plastic Profile Production Line |

|---|---|

| Brand Name: | BEISU |

| Model Number: | BS-240 |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 Set |

| Price: | Negotiable |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 10 Set per month |

| Delivery Time: | 35 working days |

| Packaging Details: | Plastic film packing and pallet fix the machine bottom |

| Material: | PVC+Caco3 |

| Products: | PVC ceiling panel profiles |

| Voltage: | 380V 50HZ 3Phase(Customized) |

| Warranty: | 12 Months |

| After-sales service provided: | Engineers available to service machinery overseas |

| Company Info. |

| Zhangjiagang Beisu Machinery Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

GF240 Twin screw extruder PVC profile production line for door panel

Application:

Plastic profiles are used more: window frames, stair railings, wire

troughs, skirting boards, shaped tubes, furniture, building

materials and other accessories. The raw materials are mainly hard

PVC, and a few are semi-hard PVC, soft PVC, polyurethane low foam

and other materials.

For hard PVC plastic profiles, there are disadvantages of poor

impact resistance, which are often modified by adding ACR, CPE,

EVA, MBS, etc. to improve the impact strength. CPE (chlorinated

polyethylene), EVA (ethylene-vinyl acetate copolymer), ACR

(acrylate), MBS (methyl methacrylate-butadiene-styrene graft

copolymer) are generally added in an amount of 6% to 10 %. MBS is

mainly used in transparent plastic profiles. EVA is best not shared

with lead stabilizers. It has poor moldability and powder spots

when used. CPE is best not shared with zinc stabilizers, and the

low temperature of CPE is not. Great.

When producing plastic profile products, process conditions such as

temperature, screw speed, traction speed etc.

Layout:

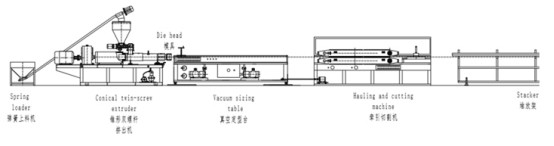

PVC Raw material+additive→Mixing Unit→Auto Feeder→Conical Twin-screw Extruder→-Moulds→Vacuum Calibration Tank→Haul-off&Cutting Machine→Stacker

Features specifications:

1.PVC Profile Extrusion Line is mainly used for the PVC corners, small boards and conduits extrusion. also can be used to produce ABS,PP,PS,PC profiles making after changing the extruder.

2.PVC Profile Extrusion Line Screw adopts oil cooling system. Barrel uses a special air cooling system .Plastics mixing uniformity, high output, wide application range, high reliability. Gear box, distribution box specially designed reinforced thrust bearings, drive torque and long service life.

3.The major part mainly adopts imported components and has a number of fault alarm function, simple operation, easy maintenance,etc.

4.The profile cutting also adopt the PLC control system, ensured the length tolerance in control.

Details specification pictures of PVC ceiling panel production line:

Main technical parameter:

| Model | SJSZ45/90 | SJSZ51/105 | SJSZ55/110 | SJSZ65/132 | SJSZ80/156 |

| Screw Diameter(mm) | 45/90 | 51/105 | 55/110 | 65/132 | 80/156 |

| Screw Speed(rpm) | 1-45.5 | 1-30 | 1-38 | 1-30 | 1-36.9 |

| Motor Power(kw) | 15/11.5 | 22/18 | 22/18 | 37/24 | 55/36 |

| Output(kg/h) | 40-70 | 60-100 | 70-150 | 80-250 | 250-400 |

| Net weight(kg) | 3000 | 3500 | 3800 | 4000 | 5000 |

| Max Width(mm) | 180 | 240 | 400 | 600 | 800 |

| Drawing Height(mm) | 140 | 140 | 140 | 140 | 140 |

| Drawing Force(fn) | 15 | 30 | 30 | 40 | 50 |

| Drawing Speed(m/s) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

| Auxiliaries Total Power(kw) | 18.7 | 31.6 | 31.6 | 31.6 | 31.6 |

| Outline Dimension(mm) | 3360*1290*2127 | 3620*1050*2157 | 3620*3500*2157 | 4235*1520*2450 | 4750*1550*2460 |

|