| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Radiator Plastic Tank Crimping Machine |

|---|---|

| Place of Origin: | Jiangsu, China (Mainland) |

| Brand Name: | WONDERY |

| Model Number: | SSKY |

| Certification: | CE |

| Supply Ability: | 100 Sets per Year |

| Packaging Details: | wooden case suitable for sea transportation |

| MOQ: | 1 Set |

| Price: | Negotiable |

| Delivery Time: | 90 days |

| machine name: | Radiator Plastic Tank Crimping Machine |

| application: | brazing radiator crimping |

| principle: | push over and pressing mechanism |

| cycle: | 200 |

| Power: | 1.5kw |

| Weight: | 1600KG |

| Company Info. |

| Wuxi Wondery Industry Equipment Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

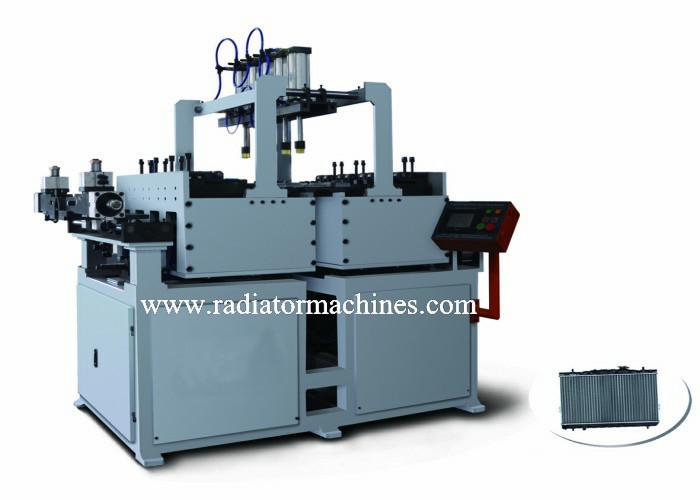

Pneumatic Type Radiator Plastic Tank Crimping Machine Manual Side Crimping

Introduction of Plastic Tank Crimping Machine

The clinching machine is used for crimping the teeth of the header plates and locking the plastic tank tight to the core body. There is a sealed space between the crimped plastic tank, sealing gasket and header plate. This servo type plastic tank crimping machine is used to handle products of various specifications. The crimping set moves step by step.

Advantages

The plastic tank clinching machine is PLC controlled, and the crimping program is set up through the touch screen which is imported from Taiwan. The touch screen can indicate the working status, and the control system stores 250 groups of radiator crimping parameters. The machine is devided into a long header and a short header crimping device which separately crimps the long header plate and the short header plate.

The plastic tank crimping machine first pushes over the header plate, and presses the header plate to the crimping level. The core is then moved to the end crimping mechanism on one side of the machine to crimp the 2 ends of the header plate by pressing the foot switch.

Company Introduction

Our company mainly supplies the radiator making machines such as aluminum fin machine, core builder, radiator plastic tank crimping machine, air leak tester, header mold, plastic tank mold, etc.

Parameters of Plastic Tank Crimping Machine

| Item | Data |

Header to header distance | 350-950mm |

Header Width | 30-120mm |

Suitable header plate length | 100-800mm |

Production Capacity | About 40 cores/hour |

Working Force | Servo + pneumatic system |

| Clinching pitch | Adjustable, default 10mm |

| Clinch machine speed | 1-20 times per minute |

| Deformation of core and header plate after clinching | Less than 0.5mm |

| Clinching tool changeover time | about 20 min |

| Servo motor power | 0.75kW x 2 |

| Air source | 0.6MPa, 0.01m3/min |

| Machine dimension | 1900 x 1800 x 2200mm (L,W,H) |

| Machine weight | 2000kg |

|