| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Chrome Powder Coat |

|---|---|

| Brand Name: | Hsinda |

| Model Number: | chrome |

| Certification: | ISO9001; SGS; ROHS |

| Place of Origin: | China |

| MOQ: | 300kg |

| Price: | 6.8-15USD/KG |

| Delivery Time: | 50000TONS/YEAR |

| Packaging Details: | Inner packing :thick plastic bag; Outer packing :export cardboard carton; Carton Size: 39*26*37cm ;Weight:20Kg/carton Gross Weight:21Kg/carton |

| Stat: | Powder Coating |

| Main Type: | Epoxy ,polyester ,epoxy Polyester Powder Coating |

| Delivery Detail: | 3-7 Days After Payment |

| Curing: | 180-200℃,10 Min-15 Min |

| Particle Size: | Average 30-42μm |

| Color: | RAL&PANTONE&CUSTOMIZED |

| Company Info. |

| Chengdu Hsinda Polymer Materials Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

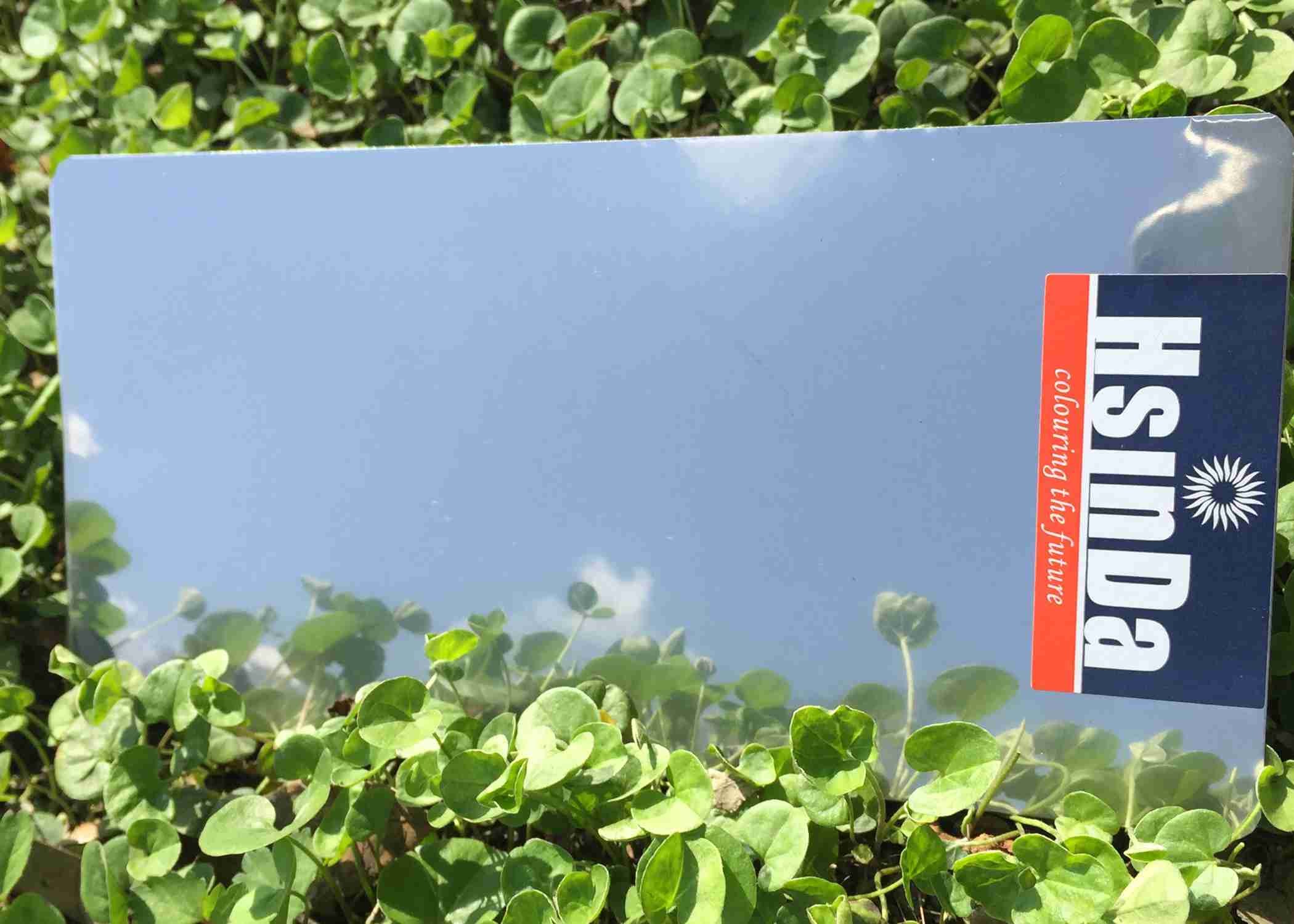

Mirror Finish Chrome Effect Electrostatic Silver Powder Coating

Product Information

Powder coating is one of the most common methods of finishing metal surgaces. Many items used everyday are powder coated, such as mailboxes, chairs, appliances, automotive parts, metal toys, car wheels, cable tray, railing, etc.

Product Advantages

Product Details

| Colour | Chrome silver powder coating | Exp. Date | 10 month | ||

| Condition | 200℃,10minutes | Testing object | 0.5mm steel plate | ||

| No. | Items | Standards | Properties | Results | |

| 1 | Appearance | Visual | Loose | Loose,There is no cluster | |

| 2 | screenings | samples | 160 mesh sieve residue free | 160 mesh sieve residue free | |

| 3 | Film appearance | visual inspection | smooth,without impurity | smooth,without impurity | |

| 4 | Film thickness | GB/T 4957 | 70-80 | 70-80 | |

| 5 | Gloss(60°) | GB/T 9754 | / | / | |

| 6 | Adhesion | GB/T 9286-1998 | 0 | 0 | |

| 7 | Pencil hardness | GB/T 6739 | H-2H | 2H | |

| 8 | Impact resistance | GB/T 1732 | front back impact 50kg/cm | Pass,no crack | |

| 9 | Bend test | GB/T 6742 | ∮≤2mm | ∮≤1mm | |

| 10 | Colour difference | GB/T 9761-1988 | △E≤1 | △E≤1 | |

Production

The polymer granules are mixed with hardener, pigments and other powder ingredients in an industrial mixer, such as a turbomixer.

The mixture is heated in an extruder.

The extruded mixture is rolled flat, cooled and broken into small chips.

The chips are milled and sieved to make a fine powder.

Chrome silver powder coating

Hsinda imitation chrome silver powder coating, the surface with high gloss, the gloss can reach more than 350%, it also known as the mirror effect powder coating. It replaces the traditional low-efficiency plating technology, shocking metal decorative effect,making your product has excellent gloss and metallic texture.

Our service

|