| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Welded Pipe Mill |

|---|---|

| Brand Name: | Tengtian |

| Model Number: | HG76 |

| Certification: | CE, ISO9001, BV |

| Place of Origin: | Hebei |

| MOQ: | 1 Set |

| Price: | $100000 to $1 million |

| Payment Terms: | L/C, T/T, Western Union, D/P |

| Supply Ability: | 100 Sets/Year |

| Delivery Time: | 2.5 months |

| Packaging Details: | Export waterproof and Seaworthy packing. |

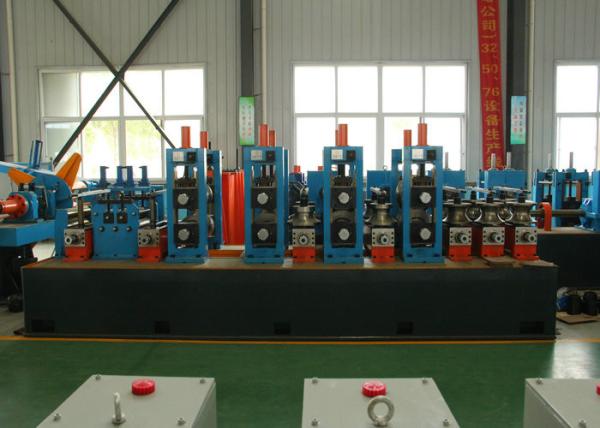

| product name: | HG76 Automatic ERW Round Tube Making Machine Carbon Steel Tube Mill |

| Model: | HG76 |

| Diameter range: | 12-76mm |

| thickness: | 1-3mm |

| Molding speed: | 30-100m/min |

| material: | Carbon steel,Stainless steel |

| motor power: | 320kw |

| keywords: | ERW Round Tube Making Machine |

| Company Info. |

| Hebei Tengtian Welded Pipe Equipment Manufacturing Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

I. Brief introduction:

76mm welded pipe production line is designed to produce welded

pipes of12mm-76mm in OD and 1mm-3mm in wall thickness, as well as

corresponding square and rectangle tube.

II. Basic Technical Information:

1.Specification of pipes

Pipe OD: 12mm-76mm Thickness: 1mm-3mm

Square tube: 25mm×25mm 70mm×70mm, Thickness: 1mm-3.0mm

Length: 6 -12m Length Tolerance: ±3mm

2.Raw Material:

Material: Carbon steel coil(GB Q195-Q345); Alloy steel coil; API 5L

X42-X80

3. Tube mill

Production Speed : 30-100m/min

Direction : left to right or right to left from operator`s side

decided by customers.

III. The technical flow of the production line

Uncoiling→Shear & butt welding→Cage looping (Accumulating)→Forming

→HFwelding→Removing & outsied Bead →Cooling→Sizing→Cutting

off→Conveying →Downloading → Packing →Warehousing

IV. Makeup of tube mill line

1. Double-reel Mechanical Uncoiler

2. Shear & Butt Welder

3. Cage Loop(Accumulator)

4. Tube mill

5. Solid State H.F. welder

6. NC Flying Saw

7. Output Rollway

8. Rollers

Our Services

1.) We will send the engineer for the installation and training

your workers how to operate this machine in correct way.

2.) Warranty Team

One year quality guarantee, life guarantee repair. Within quality

guarantee period, except for failures caused by human error, repair

parts will be provided for free. After the quality guarantee

period, only charge the cost of the spare parts.

3.) We supply the pre-sell and after-sell service.

pre-sell service: workshop design, and production output design

after-sell service: installation and training, and the skilled

engineer for working.

4.) We can also sent the engineer working for you serval months or

1 year. The engineer will help you to improve the output, reduce

the waste and decrease the cost.

5.) We supply the pre-sell service-Design for whole project for

stainless steel pipe making/ carbon steel pipe making.

6.) We will be responsible for the loading and shipping

|