| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Tungsten Carbide Cutting Tools |

|---|---|

| Brand Name: | CTCP-AP |

| Model Number: | VBMT160404-MV, VBMT160408-MV |

| Certification: | ISO |

| Place of Origin: | China |

| MOQ: | 1 pieces |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Paypal, |

| Supply Ability: | 300000 pieces per month |

| Delivery Time: | turning inserts VBMT1604 in stock can be sent within 3-5 days, no stock usually about 20-25 days |

| Packaging Details: | 10 pieces packed in one plastic box |

| Type: | turning inserts VBMT1604 |

| Material: | Tungsten carbide |

| Chip breaker: | MV |

| Grade: | YP731 |

| Application: | For stainless finishing,semi finishing and roughing machining |

| Vc: | 180m/min |

| Ap: | 1.0mm |

| fn: | 0.1mm/r |

| Insert empress cape: | 5 degree |

| Nose R: | 0.4mm and 0.8mm |

| Color: | Black |

| Coating: | PVD |

CNC insert cutting tools cemented carbide hard alloy turning inserts VBMT1604 for lathe stainless steel machining

The definition of turning inserts

Carbide inserts are used for cutting all kinds of metals.Because of its high hardness and strength,it is the most common material for cutting inserts now.People used to use brazed inserts tips,but due to low efficiency,brazed inserts have been mostly replaced by carbide coating inserts nowadays,which are indexable with coating,life time much longer and also with high accuracy and efficiency.

Models introduction:

Specification | Grade | Description | Coating |

| VNMG160404-MV | YP730 | Suitable for light and medium processed materials as well as finishing and semi finishing of stainless steel and high temperature alloy | PVD coating |

| VNMG160408-MV | YP730 | Suitable for light and medium processed materials as well as finishing and semi finishing of stainless steel and high temperature alloy | PVD coating |

| VNMG160404-MV | YP731 | Generally suitable for the processing of stainless steel and high

temperature alloy | PVD coating |

VNMG160408-MV | YP731 | Generally suitable for the processing of stainless steel and high temperature alloy | PVD coating |

Contrast Advantage/Benefits of choosing tungsten carbide inserts:

1. Tungsten carbide insert has new Cutting edge technology with better quality and longer tool life.

2. Advanced production machine ensure stable excellent quality

Initial considerations for turning

These initial considerations will affect the choice of turning

tools and how they are applied.

The component

Consider the following dimensions and quality demands of the component to be machined:

Type of applications, for example, longitudinal or profiling, internal or external

Type of methods, for example, roughing or finishing

Large, stable component

Small, long, slender, thin-walled component

Corner radius

Quality demands (tolerance, surface finish etc.)

After considering the features, look at the component:

Does the material have good chip-breaking qualities?

Is chip evacuation a critical issue? Mass production justifies an optimized Tailor Made tool to maximize productivity

Batch size, a single component or mass production?

Can the component be fixed securely?

The machine

Machine considerations include:

Stability, power and torque, especially for larger components

Coolant supply or dry machining

Is high pressure coolant for chip breaking in long-chipping materials necessary?

Tool changing times/number of tools in turret

Limitations in rpm, especially for bar feed magazine

Sub-spindle, or tail stock available?

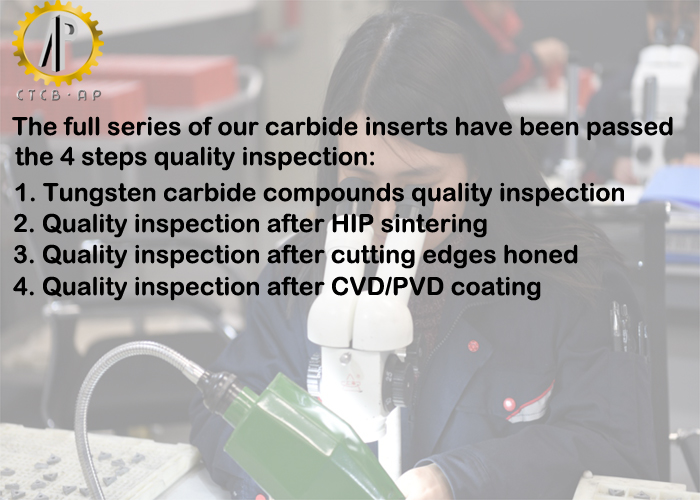

Quality control:

Technical support and after-sale service:

Our company can providing the following technical service for customers:

1. Recommending more suitable processing parameters.

2. According to the workpiece design, material and CNC machine feed rate, cutting speed we can recommending a full set of practical scheme.

3. Suggsting more suitable model to replace the brands of Japan, Korea and so on.

4. We can offer together with tool holder.

|