| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Oil Bottling Machine |

|---|---|

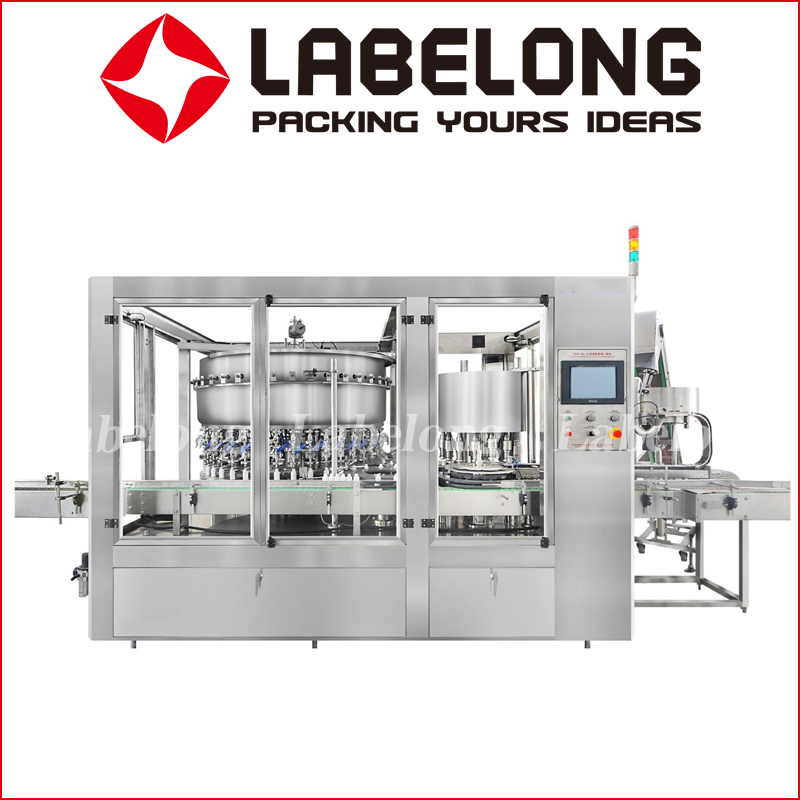

| Brand Name: | Labelong |

| Model Number: | GYF 16-5 |

| Place of Origin: | Jiangsu |

| MOQ: | One set |

| Price: | Negotiable |

| Payment Terms: | T/T. L/C |

| Supply Ability: | 50-100SET/YEAR |

| Delivery Time: | 30-60 working days |

| Packaging Details: | Wooden case |

| Certification: | Ce ISO |

| Model: | GYF 16-5 |

| Control: | PLC control |

| Working: | Automatic |

| Certification:: | CE,BV,SGS |

| Capacity: | 3000-10000bph |

| Structure: | Rotary |

Application: edible oil, cooking oil,lubricant, detergent, other viscous liquid, etc.

Suitable for: HDPE / PET bottles with all volumes and shapes

Filling system: vacuum gravity filling

Production capacity: 3000BPH – 10,000BPH (500ML)

Introduction of edible oil filling machine:

GYF series edible oil filling machine is special for edible oil / viscous liquid filling, capping and

equipped with rotary transmission, PLC and frequency adjuster in

speed. It is innovated and designed in the requirement of edible

oil / viscous liquid filling technics, on the bases of introducing,

digesting and absorbing advanced technology abroad. It is

reasonable in structure, safe to operate and easy to maintain,

which is an ideal choice for edible oil producers.

Filling Line Production Plant is one of advanced models which is our company combines international advanced self-filling process and technology developed specifically for mineral water, pure water and other non-gas beverage filling installation.

A. Direct connection technology between air conveyor and in-feeding

starwheel is applied to replace in-feeding screw and conveying

chain to ease bottle changing process with only to change few

parts. Newly-designed bottle-separating grippers are assembled to

starwheel.

B.We adopts Neck-hanging technology in bottle transportation.

Instead of traditional starwheel, we use neck-hanging gripper to

make bottle-size-changing easily , without equipment height

adjustment ,only few parts need to be adjusted

C. Specially-designed rinser grippers which are made of stainless

steel are firm and endurable, with no contact to screw part of the

bottle to prevent second pollution.

D. High-speed, easily-cleaned filling valves with big flow volume

are equipped with well CIP system and control system to rinse the

equipment thoroughly.

E. splint of starwheel using twist descending way to simplify the

process of bottle-size-changing. Only need to change arch board and

starwheel, within ten minutes.

Our Production

Our ProductionLabelong focus on filling, packing & water treatment field, our

factory takes up 60000 square meters ,more than 30 Professinal

Tehchnicians and workers which is one of the professional &

reliable Chinese manufacturers & provider for liquid & semi-liquid

filling & packaging machinery, blow molding machines and water

treatment systems with reliable quality & pretty good after sale

service with CE certification & ISO9000:2001 certification.

| No. | Production line category | Capacity |

| 1 | Hot filling production line | 3,000-36,000BPH |

| 2 | Beverage processing System | 1,000 Ltrs/H to 10,000 Ltrs/H |

| 3 | Bottled water production line | 3,000-36,000BPH |

| 4 | 5L Large capacity bottled water production line | 700-5,000BPH |

| 5 | Carbonated drink production line | 3,000-18,000BPH |

| 6 | Pulp juice production line | 5,000-22,000BPH |

| 7 | Oil Filling line | 3,000-10,000BPH |

| 8 | Linear Filling machine | 300-900BPH |

| 9 | Bottlle Unscrambler | Up to 20,000BPH |

| 10 | Barrelled water production line | 300-2000 bucket/H |

| 11 | Water Treatment system | 1,000 Ltrs/H to 10,000 Ltrs/H |

| 12 | OPP Labeling machine | 6,000-24,000BPH |

| 13 | PVC Shrink Sleeve Labeling machine | 6,000-24,000bph |

| 14 | Automatic Blow molding machine | 1,000-7,000BPH |

| 15 | Full-automatic Film Wrapper & Shrinker | 8-20 Packs per Minutes |

This is part machines.want to know more machine information,you visit our website derictly

www.labelong.com

|