| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | PE Pipe Extrusion Line |

|---|---|

| Brand Name: | LB |

| Model Number: | LB |

| Certification: | CE,ISO |

| Place of Origin: | ZHANGJIAGANG |

| MOQ: | 1 SET |

| Price: | negotiation |

| Payment Terms: | L/C, T/T, |

| Supply Ability: | 15 SETS PER MONTH |

| Delivery Time: | 45 WORKING DAYS |

| Packaging Details: | WOODEN BOX |

| Material: | PE |

| Screw Diameter: | 65mm |

| LD Ratio: | 33:1 |

| Warranty: | 1 Year |

| Motor: | Siemens |

| Screw design: | Single-screw |

| Voltage: | Customer demand |

| Automatic grade: | Full-automatic |

| After-sales service provided: | Engineers available to service machinery overseas,Online support,Video technical support,Field installation,commissioning and training |

| Color: | Customised |

| Control: | PLC+Touch Screen |

| Processing type: | Extrusion Machine |

| Company Info. |

| Zhangjiagang Langbo Machinery Co. Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

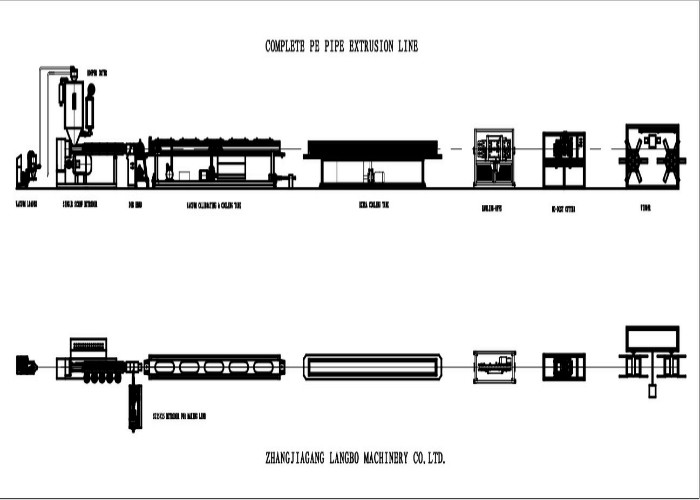

65mm PE Pipe Extrusion Line Hdpe Pipe Extrusion Machine 1 Year Warranty

Description:

This PE pipe extrusion line can be used in HDPE Large Diameter Gas

and Water Pipe which has excellent stiffness and flexibility, heat

resistance, aging resistance, high mechanical strength, the

resistance of environmental stress cracks, resistance to creep

deformation, heat-linkage, and so on. So, it is a preferred gas and

water pipe for a ductwork system between the city and its suburb,

Large diameter HDPE pipes start to play a very important role in

the city water and gas supply systems.

Main Features:

1.Extruder adopts big L/D and multi mixing structure, which is more suitable for the PE PP PPR low temperature extrusionproduction.

2.Specially-designed spiral moulds for PE PP PPR pipes with marking

line, with inside oil controlling temperature system

3.Beautiful and practical stainless steel body for the vacuum

calibration and spray cooling system, unique multi-section vacuu

system ensures the stable sizing and cooling for pipes with marking

line; special spray cooling system improves the cooling efficiency

; special water position, water temperature system make the machine

more intelligent.

4.Hauling-off unit adopts particular pedrail structure, which is

easy and convenient for operation; pedrail clamping uses mechanical and pneumatic combining system, which is more reliable.

5.Cutting system adopts saw blades and planetary cutting means;

sumping uses hydraulic system , which ensures the smoot cross

section; equipped with dust-collecting unit, which ensures the

clean working environment.

Specification of Production lines:

| Model | Screw Diameter | L/D | Pipe Range(mm) | Machine Motor Power (kw) | Total Power(kw) | Line Length (M) |

| PE-63 | 65mm | 33:1 | 16-63 | 37 | 80 | 24 |

| PE-110 | 65mm | 33:1 | 75-110 | 55 | 110 | 30 |

| PE-160 | 75mm | 33:1 | 90-160 | 90 | 150 | 32 |

| PE-250 | 75mm | 33:1 | 110-250 | 110 | 200 | 42 |

| PE-315 | 90mm | 33:1 | 160-315 | 160 | 240 | 44 |

| PE-400 | 90mm | 33:1 | 200-400 | 185 | 300 | 50 |

| PE-500 | 120mm | 33:1 | 250-500 | 280 | 350 | 56 |

| PE-630 | 120mm | 33:1 | 315-630 | 280 | 480 | 56 |

| PE-800 | 150mm | 33:1 | 400-800 | 315 | 550 | 72 |

Pre-sales service:

After-sales service:

|