| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Compound Fertilizer Granulator |

|---|---|

| Brand Name: | Tianci |

| Model Number: | DZJ-II-1.0 |

| Certification: | SGS BV ISO |

| Place of Origin: | Zhengzhou China |

| MOQ: | 1PC |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 20 pcs per day |

| Delivery Time: | 15 Days |

| Packaging Details: | Package or Container |

| Material: | Carbon steel |

| Model: | 1mm-15cm |

| Weight: | 1.2T |

| Capacity: | 1-4 t/h |

| Suit for: | NPK Compound fertilizer |

| Warranty: | 12 Months |

| Pellet Diameter: | 2-10mm |

| Voltage: | 380V |

| Usage: | Making fertilizer granules |

| Company Info. |

| ZHENGZHOU SHENGHONG HEAVY INDUSTRY TECHNOLOGY CO., LTD. |

| Verified Supplier |

| View Contact Details |

| Product List |

NPK Fertilizer Granulator Machine , Double Roller Press Granulator

Product Introduction

The electric motor drives the pulley, and the transmission belt is transmitted through the speed reducer to a pair of two high-pressure roller bodies with a sliding mold shell to perform relative work.

The DZJ-I extruder has two rollers interacting with each other by the work of a pair of split gears.

The two rollers of the DZJ-II extruder are driven directly by two output shafts on a dedicated reducer to achieve the purpose of extrusion.

During the production, raw materials enter the hopper and are pressed and formed by the high-pressure roller body. After the mold is released, it flows to the crushing and forming part in the lower part of the roller body.

The power of crushing and forming is the relative movement of a pair of crusher rollers driven by the sprocket of the active press roller shaft via a chain drive.

After crushing and screening in the working chamber, the finished particles pass through the screen to the discharge then come out of the machine.

Description of Granulator

It has the advantages of beautiful appearance, simple operation,

low energy consumption, long service life and high granulation

rate. It is the most advanced compound fertilizer granulation

equipment in China, and it is a kind of advanced compound

fertilizer granulation equipment, Products throughout the country.

The series of granulator for a wide range, with the following

characteristics:

1. No drying process, room temperature granulation, a molding, less

investment, quick, good economic returns.

2. Powerful operation is reliable, no waste discharge, stable

operation, easy maintenance, process layout is reasonable, advanced

technology, low production costs.

3. Raw materials are widely used for granulation of various raw

materials such as compound fertilizer, medicine, chemical industry,

feed, coal, metallurgy and so on, and can produce various kinds of

concentrations, including organic fertilizer, inorganic fertilizer,

biological Fertilizer, magnetic fertilizer, etc.) compound

fertilizer.

4. In particular, rare earth, ammonium bicarbonate, ammonium

sulfate compound fertilizer granulation, to fill the gaps, ranking

the leading domestic level, is the national environmental

protection technology for the promotion of the project.

Technical Parameters

| Model | DZJ-I 1.0 | DZJ-I 2.0 | DZJ-I3.0 | DZJ-I 4.0 | DZJ-II 1.0 | DZJ-II 2.0 |

| Capacity | 1-1.5 | 1.5-2.5 | 2.5-3.5 | 3.5-4.5 | 1-2 | 1.5-2.5 |

| Power | 15Kw | 18.5Kw | 30Kw | 45Kw | 15Kw | 18.5Kw |

| Press Roller | Φ150×22O | Φ150×30O | Φ186×30O | Φ300×30O | Φ150×22O | Φ150×30O |

| Feed Size | 0.5mm | 0.5mm | 0.5mm | 0.5mm | 0.5mm | 0.5mm |

| Product Size | Φ2.5~Φ10 | Φ2.5~Φ10 | Φ2.5~Φ20 | Φ2.5~Φ20 | Φ2.5~Φ10 | Φ2.5~Φ10 |

| Speed Reducer | ZQH350 | ZQH400 | ZQH400 | ZQH500 | ||

| Material Mositure | 2%~5% | 2%~5% | 2%~5% | 2%~5% | 2%~5% | 2%~5% |

Granule Strength and Apperance Type:

Shape of finished products | oval, irregular, wheat shaped, etc., can also be customized according to customer requirements. |

Material moisture requirement | not more than 10% |

The rate of ball formation | 95% |

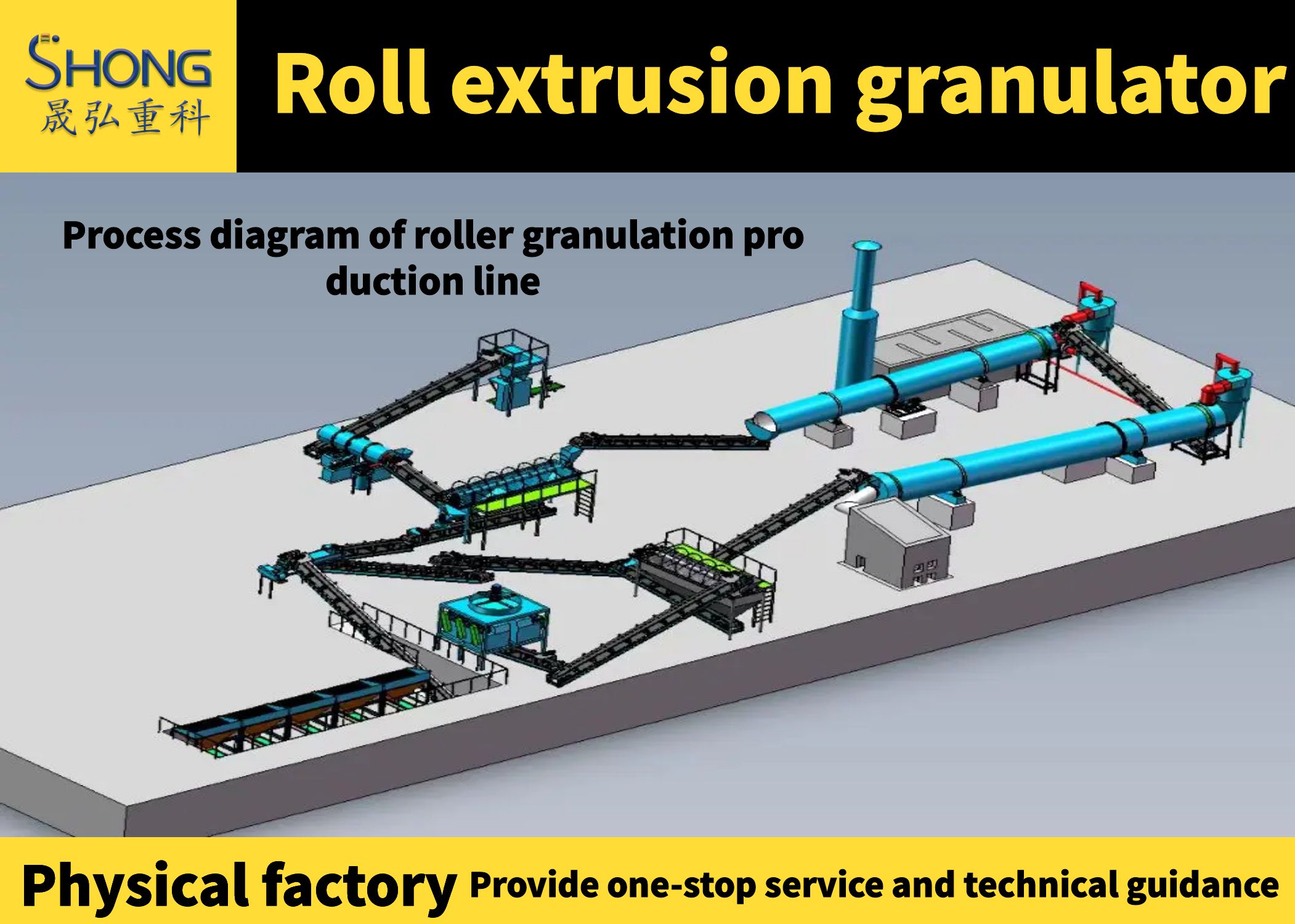

Output | 1-4t/h ( can combine multiple granulators work together to increase output, see below technical process chart). |

Granule size | 3-8mm (popular market granule diameter: 2.8-4mm) |

Product Introduction

The electric motor drives the pulley, and the transmission belt is

transmitted through the speed reducer to a pair of two

high-pressure roller bodies with a sliding mold shell to perform

relative work.

The DZJ-I extruder has two rollers interacting with each other by

the work of a pair of split gears.

The two rollers of the DZJ-II extruder are driven directly by two

output shafts on a dedicated reducer to achieve the purpose of

extrusion.

During the production, raw materials enter the hopper and are

pressed and formed by the high-pressure roller body. After the mold

is released, it flows to the crushing and forming part in the lower

part of the roller body.

The power of crushing and forming is the relative movement of a

pair of crusher rollers driven by the sprocket of the active press

roller shaft via a chain drive.

After crushing and screening in the working chamber, the finished

particles pass through the screen to the discharge then come out of

the machine.

|