| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Sodium Hypochlorite Generator |

|---|---|

| Brand Name: | GEEMBLUE |

| Model Number: | GBS-10K-NACLO |

| Certification: | ISO9001 CE |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD 148000 ~ 158000 /set |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 20 set/ month |

| Delivery Time: | 40-45 work days |

| Packaging Details: | wooden case |

| Active Chlorine Production: | 10 KG/H |

| Concentration of liquid: | 7 mg/l - 9 mg/l |

| Salt consumption: | 3.5 kg / kg Cl2 |

| Energy consumption: | 4 KWH / kg Cl2 |

| Input power: | 380V, 50Hz |

| Electrolytic liquid: | 2.5% - 3% weak brine |

| Working way: | 24 hours Automatic |

| Rated current: | According to the specific choice model |

380V 50Hz PLC Control Split Type Water Electrolysis Machine For Sewage Treatment Plant

Brief Introduction:

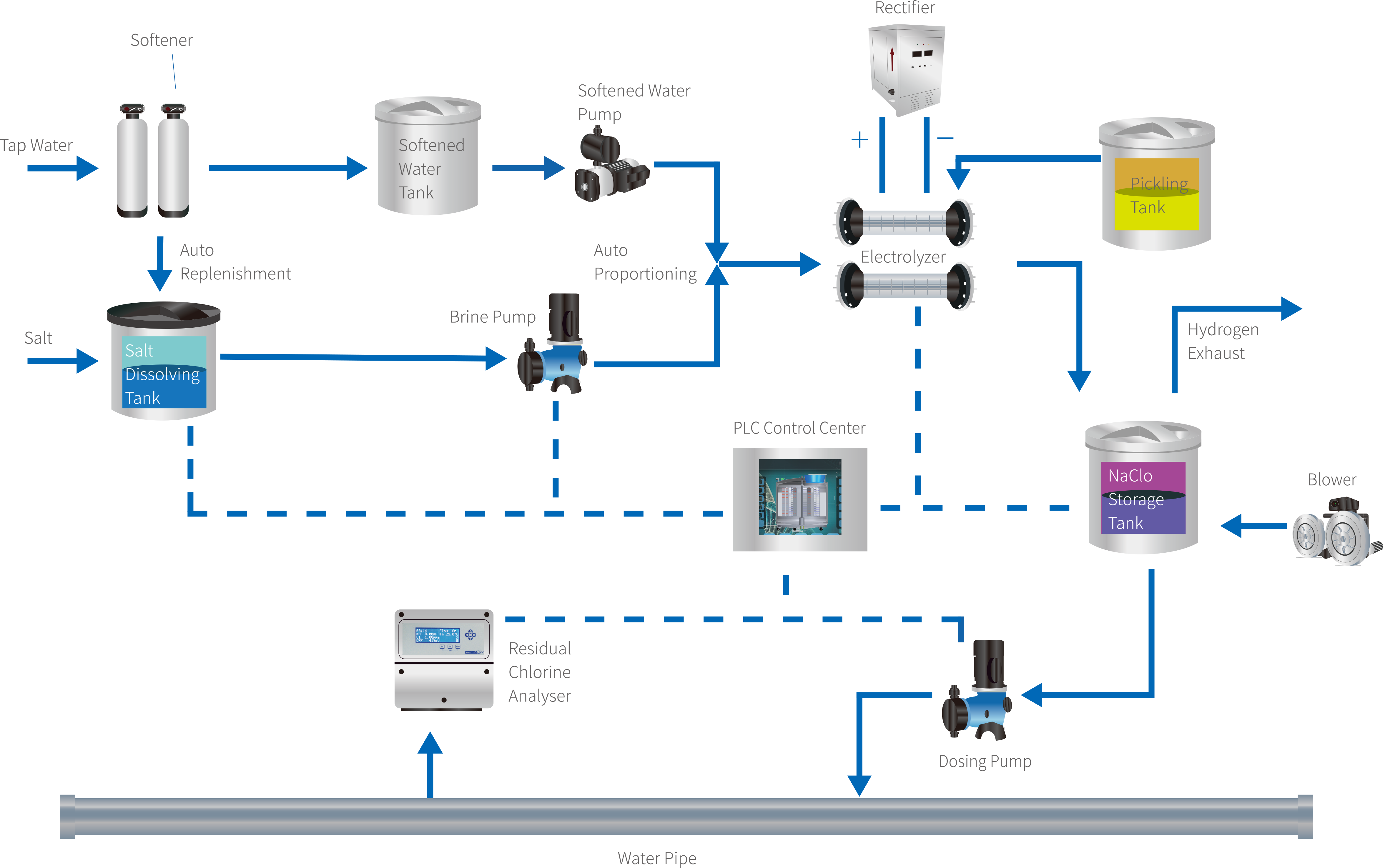

Sodium hypochlorite generation system is producing sodium hypochlorite through brine electrolysis, and the whole system is a combination of Softening unit, Filtration unit, Salt dissolving unit, Online proportioning unit, electrolytic unit, rectifier power supply, automatic control systems, storage and dosing unit, etc.

Process

1. Influent water is passed through a water softener.

2. Using softened water to dissolve the salt in a tank to form a concentrated brine solution.

3. Diluted into 2.5%-3% after filtered (If use sea water as raw material, it will be treated before electrolysis)

3. The diluted brine is electrolyzed to a 0.8% solution of sodium hypochlorite.

4. The 0.8% hypochlorite solution flows into a storage tank.

5. The sodium hypochlorite solution will be injected into the pipe

by metering pump.

6. The residual chlorine detector will monitor residual chlorine and return feedback to the PLC center.

7. According to preset standards, the PLC Center will adjust the speed of the dosing pump.

Feature and Benefit

♫ Eliminates hazards associated with gaseous Cl2. More stable than

bulk sodium hypochlorite.

♫ Safe and clean on-site production.

♫ Safe and economical using only salt, water and electricity.

♫ Eliminate transportation and handling of gaseous chlorine or bulk

sodium hypochlorite.

♫ Skid mounted, fully integrated systems.

♫ Automatic, local or remote operation.

♫ Easily integrates with all chlorine analyzers and dose control

systems.

♫ Stable and repeatable levels of free chlorine at the end of your

distribution system.

Comparative advantages of chloridose

| Disinfection system | Source of raw materials | Handling of product | Self-life of product | Operation & maintenance | Cost of consumable |

| Chloride hypochlorite | Only Edible salt | No transportation & storage Easy handling | Produced and dosed on site. No storage. No loss of chlorine | Very Easy | Very Economical |

| Chlorine gas | Dependent on Supplier uneconomical for transport | Transportation and Handling is hazardous | Stable | Difficult | Most Economical |

| Bleaching powder | Dependent on supplier | Handling and storage is inconvenient messy | Highly unstable Rapidly losses Chlorine on storage | Inconvenient Difficult & Messy | Expensive |

| Commercial sodium hypochlorite | Dependent on supplier & Uneconomical for Transport | Handling and storage is inconvenient | Unstable & losses chlorine on storage | Fairly Easy | Most Expensive. |

Specifications:

| Model | FAC capacity | Water treatment capacity | Salt consumption | Power consumption | FAC concentration | Dimensions |

| GBS-10K-NACLO | 10 kg / h | 200000 ton / day | 3.5 kg / kg Cl2 | 4 kwh / kg Cl2 | 7000~9000 ppm | 2000*800*1600 mm |

|