| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Water Gate Valve |

|---|---|

| Brand Name: | AFC, OEM |

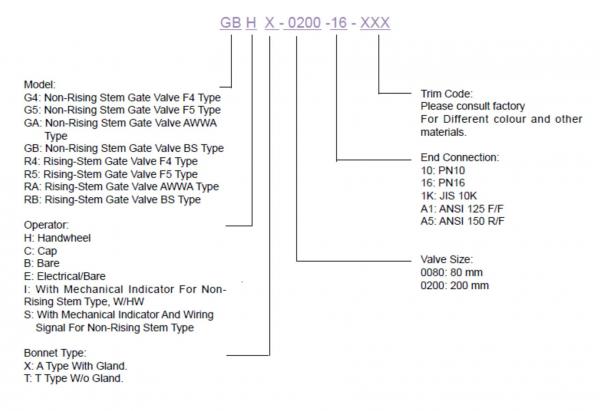

| Model Number: | GBCX, GBHX |

| Certification: | WRAS, CE |

| Place of Origin: | China |

| Price: | Price Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 days for two containers |

| Delivery Time: | 45-60 days |

| Packaging Details: | Plywood cases packing |

| MOQ: | 1 |

| Product Name: | Gate Valve |

| Material: | GJS500-7 |

| Color: | Blue , Red |

| Standard: | EN1074-2 |

| Stem: | SS420,SS431 |

| Nut: | Brass, Bronze |

| Operator: | Hand wheel, Cap |

| Pressure Rating: | PN10/PN16/PN25 |

| Company Info. |

| Suzhou Alpine Flow Control Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

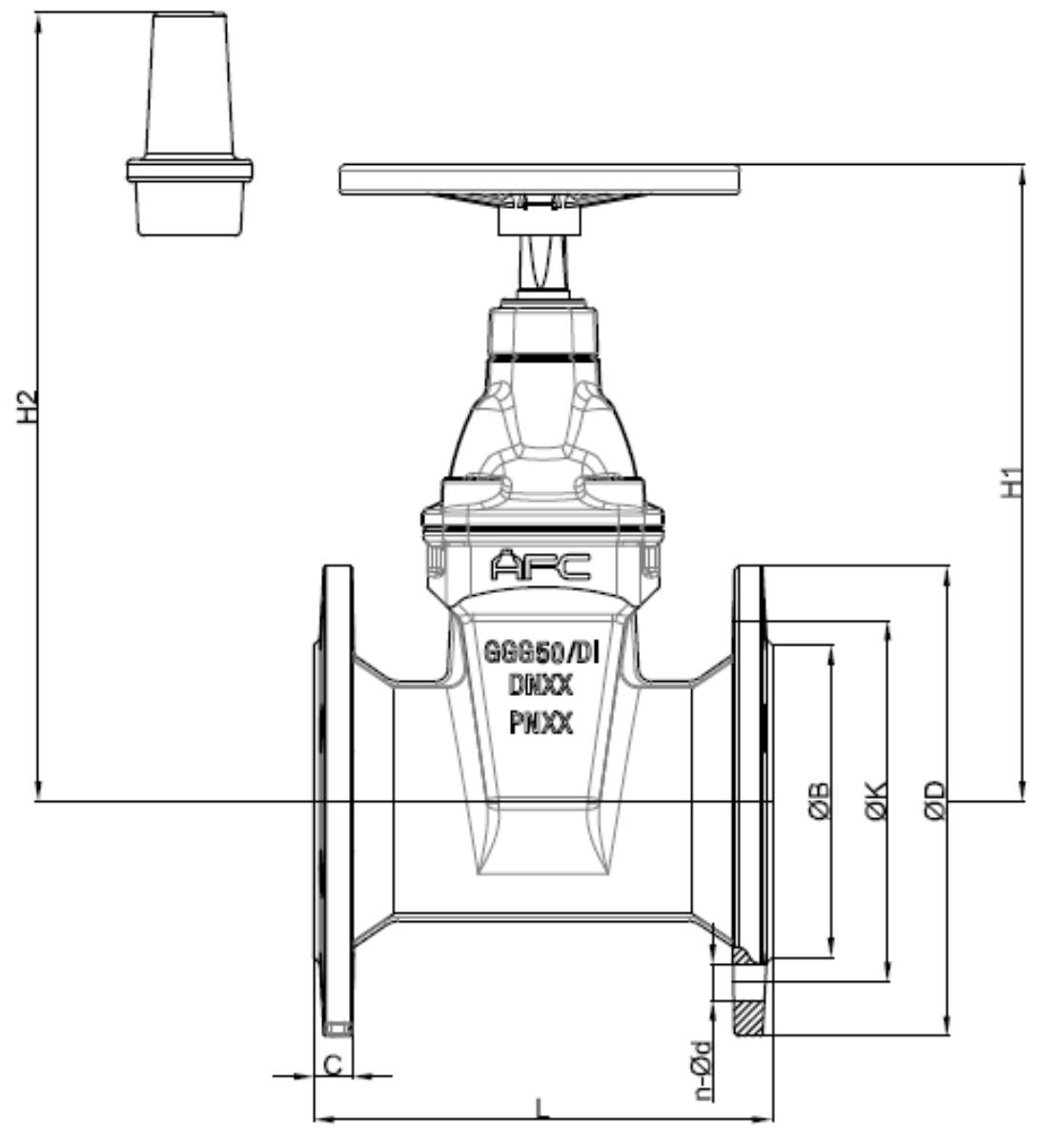

Resilent Seated Gate Valve, Ductile iron, Non Rising Stem EPDM/NBR Wedge Available

Decription:

Resilient seated gate valve is a soft seal disc which is fully encapsulated with EPDM or NBR rubber. The valve is designed with new technology for light operating, no clogging and no corrosion, good resilient memory & long service life. It can be used extensively in all kinds of water supply & sewage, fire-fighting and function as a shut-off or regulating valve.

Features:

• Newly advanced design, less operation torgue & abrasion resistance.

• Body & bonnet are made of high grade ductile Iron GJS500-7

• Disc is designed with an abrasion resistant nylon guide which can

help less opening or closing torgue and smooth during operation.

• Forged stem provide stronger stem operation and less moving

parts.

• Disc is covered by high-grade rubber which meet drinking water

standard.

• High-tech rubber curing with precise geometry dimensions, more

resilient & strong adhesive to ductile casting.

• The 4 O-ring stem seals are designed to prevent stem leakage. and

provide replacement of the O-ring without disassambling of valve

from mainline pipes.

• Both inside & outside are coated with epoxy resin powder.

• Manufacturing standard meets BS EN 1074-1, EN1074-2, BS 5163, BS

EN 1171.

• F/F (Face to Face) meets the following standard: BS EN558-1.

• Bolts are protected by silicon glue.

Production Process:

1. Shot blasting

2. Coating with FBE

3. Assembling

4. Testing - Shell 1.5*PN, Seat 1.1*PN, 100%

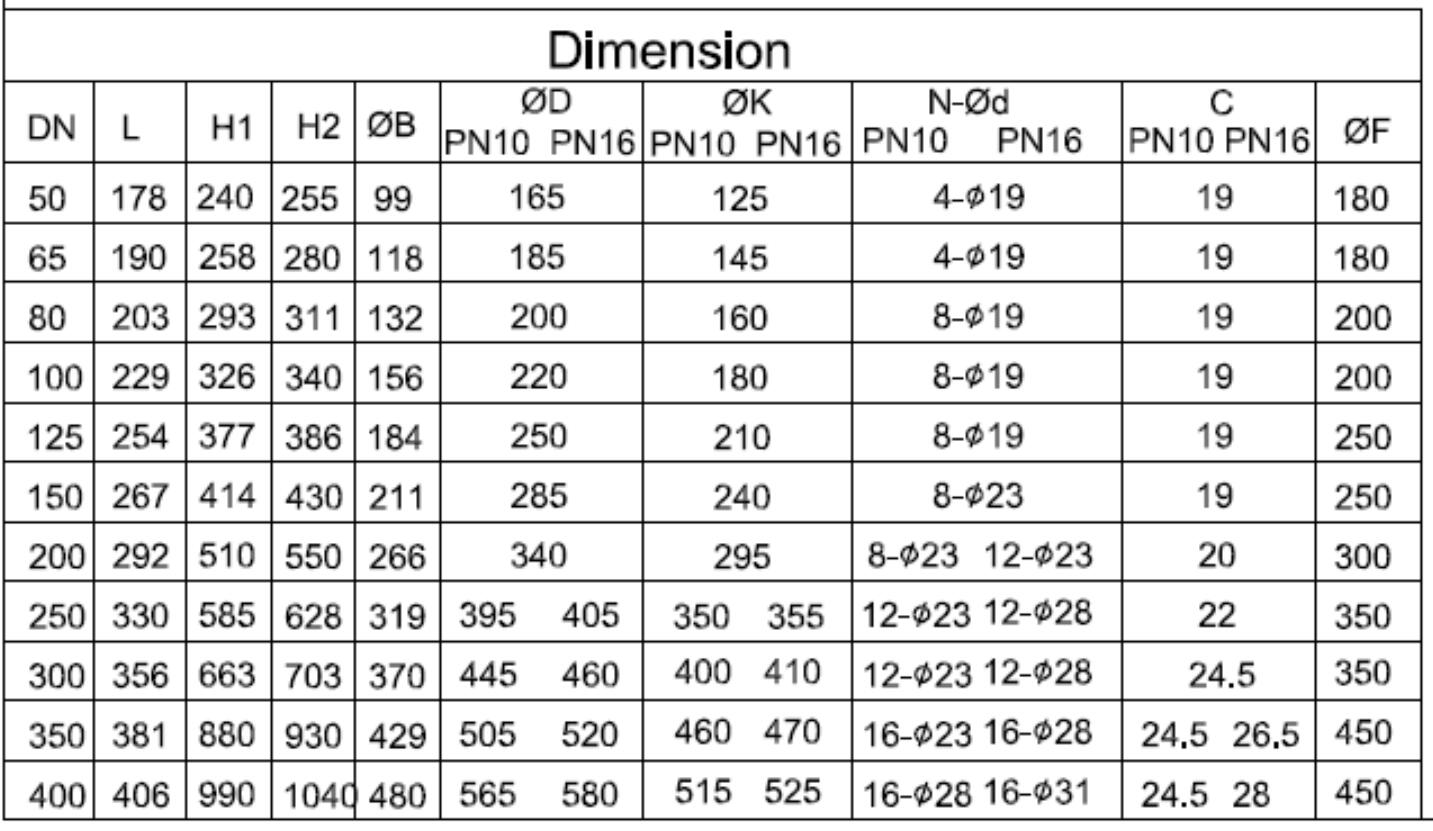

Size Range: DN50~DN600mm

Pressure Rating: 1.0Mpa; 1.6Mpa; (2.5MPa Up to DN300)

Working Temperature:-10℃- 80℃

Flow Media: Water, Sewage

End Connection: PN 10/ 16, PN25 is available up to DN300

Material:

Body | DI GJS500-7 |

Bonnet | DI GJS500-7 |

Gland | DI GJS500-7 |

Wedge | DI GJS500-7 with fully vulcanized EPDM |

Stem | SS420/SS431 |

Stem nut | Brass/Bronze |

|