| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Thermal Evaporation Coater |

|---|---|

| Brand Name: | ROYAL |

| Model Number: | RTEP |

| Certification: | CE |

| Place of Origin: | Made in China |

| MOQ: | 1 set |

| Price: | negotiable |

| Payment Terms: | L/C, T/T, D/A, D/P |

| Supply Ability: | 15 sets per month |

| Delivery Time: | 8 weeks |

| Packaging Details: | Export standard, to be packed in new cases/cartons, suitable for long-distance ocean/air and inland transportation. |

| Chamber: | Vertical orientation, 2-doors |

| Evaporation Source: | Thermal filament, thermal boat, thermal box, rod, crucibles |

| Deposition Materials: | Aluminum, gold, silver, chromium, copper, Indium, Indium Tin Oxide, Nickel |

| Coating Colors: | rainbow multiple colors, green, blue, gold, silver, red, black, matt gold, matt silver etc. |

| name: | Bottle Caps Vacuum Metalizing Machine |

| purpose: | Decorative and aesthetic coating |

| Factory Location: | Shanghai city, China |

| Worldwide Service: | Poland - Europe; Iran- West Asia & Middle East, Turkey, India, Mexico- South America |

| Training Service: | Machine operation, maintenance, coating process Recipes, program |

| Warranty: | Limited warranty 1 year for free, whole life for machine |

| OEM & ODM: | available, we support tailor made design and fabrication |

| Company Info. |

| SHANGHAI ROYAL TECHNOLOGY INC. |

| Verified Supplier |

| View Contact Details |

| Product List |

Beverage bottles Thermal Evaporation Coating Unit / Bottle Caps Vacuum Metalizing Machine

Beverage bottles Thermal Evaporation Coating Unit is widely used for injection plastic bottles, plastic caps for wine bottle caps, cosmetic caps, beverage bottles, beverage bottle caps, medicine bottle caps etc.

All for Decorative and aesthetic coating purpose to get various colors: rainbow multiple colors, green, blue, gold, silver, red, black, matt gold, matt silver etc.

Beverage bottles Thermal Evaporation Coating Unit Advantages

Finishes are deposited using an environmentally friendly green

process;

Highly reflective, brilliant and bright colors;

High volume production, low cost, ideal solution for mass

production demand.

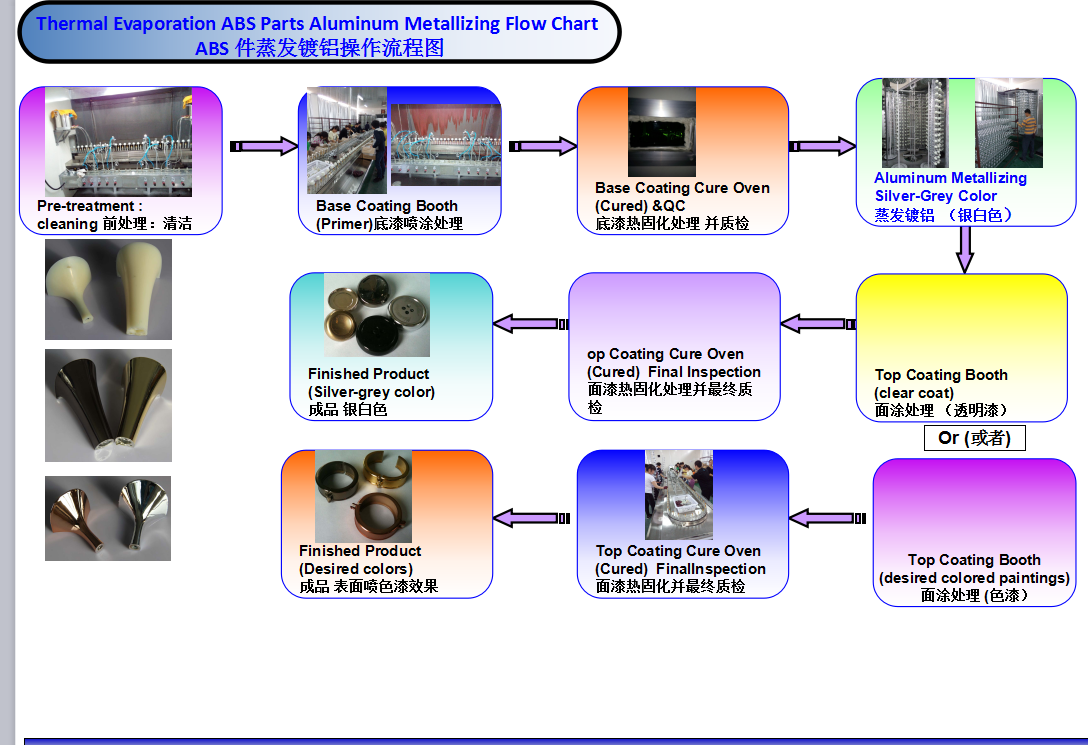

Plastic Bottles Caps Thermal Evaporation Coating Unit Coating Process

Take an example of ABS plastic part

Beverage bottles Thermal Evaporation Coating Unit Models (Standard)

| Model | Size(mm) | Substrate Jigs (Qty.) | Evaporation Power(kVA) | Plasma (kVA) | Ultimate Vacuum | Cycle Time | Electrical Power |

| RTEP1012 | Φ1000xH1200 | 6,8,10 | 20 | 7 | 8x10-4Pa | 10'~15' depends on Product | 3Phase/AC380V,50HZ |

| RTEP1416 | Φ1400xH1600 | 6, 8,16 | 30 | 7 | |||

| RTEP1418 | Φ1400xH1800 | 6,16 | 35 | 10 | |||

| RTEP1616 | Φ1600xH1600 | 8.16 | 35 | 10 | |||

| RTEP1618 | Φ1600xH1800 | 8.16 | 35 | 10 | |||

| RTEP1820 | Φ1800xH2000 | 6 | 40 | 10 | |||

| RTEP2022 | Φ2000xH2200 | 10,12,16 | 40 | 10 |

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions.

|