| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Medical Plastic Injection Molding |

|---|---|

| Brand Name: | OEM/ODM |

| Model Number: | HW-006 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 2000 pieces |

| Price: | 2.55-5.55usds |

| Supply Ability: | 100000 pieces |

| Delivery Time: | 25-30days |

| Packaging Details: | PE bag , as customer requested |

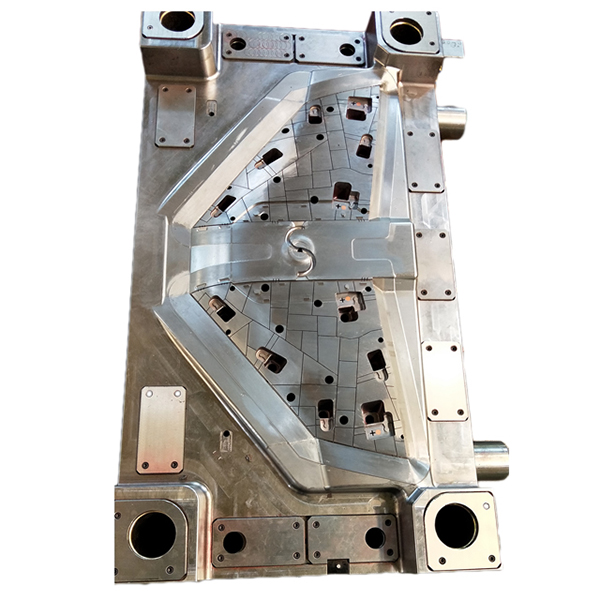

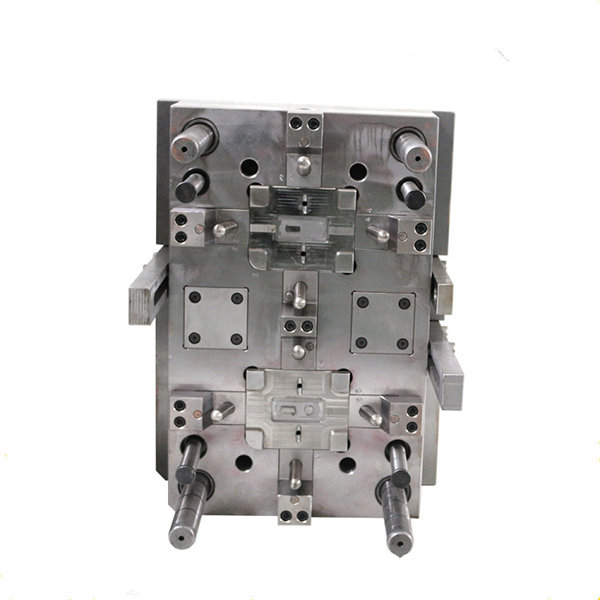

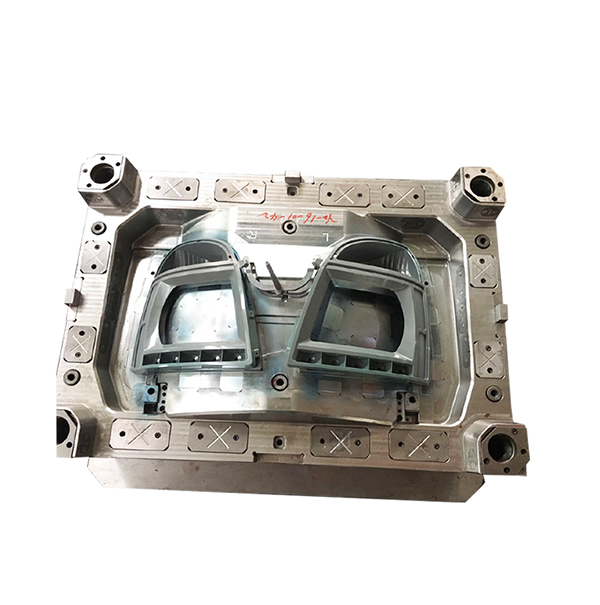

| Core&Cavity Material: | S136HRC48-52 Injection Plastic Parts |

| Mould Type: | Mould with Lifter |

| Product Material: | ABS |

| Main Technique: | Milling Grinding EDM |

| Design Software: | E AutoCad |

| Probe CNC Coordinate Measuring Machine: | 2d/3d coordinate measuring tester |

| Longevity: | 0.5-1 million shots |

| Surfce Treatment: | Texture Polishing |

Multi Cavity Plastic Injection Tooling For Automotive Spare Parts

Gate type:side gate, Sub gate, Pinpoint gate, Edge gate, etc

| Mold information | content |

| Product Material | ABS,PP,PC,PA,PMMA,PS,POM and etc. |

| Moldbase | FUTABA,LKM,HASCO,DME you can choose |

| Cavity material | 45#,50#,P20,H13, 718 2738, NAK80, S136, SKD61 etc |

| Runner | Cold/Hot runner |

| Cavity | Multi or single cavity |

| Standard parts | Hasco |

| Treatment | Heat treatment and Nitriding, polish, etc. |

| HRC | H45~52 |

| Product weight | 50~5000 K |

| Machine type | 250Ton |

| The standard of appearance of the products for stripe | MT(Mold Tech),YS,HN series |

| The way of Color contrast | RAL K7, PANTONE |

| 1.Quote | According to the sample, drawing, and specific requirement. |

| ↓ | |

| 2.Discussion | Mold material, cavity number, price, runner, payment, etc. |

| ↓ | |

| 3.S/C Signature | Approval for all the items |

| ↓ | |

| 4. Advance | Pay 50% by T/T |

| ↓ | |

| 5.Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send the customer the report. |

| ↓ | |

| 6.Mould Design | We make mould design on the basis of confirmed product design, and send it to customers for confirmation. |

| ↓ | |

| 7.Mold Tooling | We start to make mold after mold design confirmed |

| ↓ | |

| 8.Mold Processing | Send report to customer once each week |

| ↓ | |

| 9.Mold Testing | Send trial samples and try-out report to customer for confirmation |

| ↓ | |

| 10.Mold Modification | According to customer's feedback |

| ↓ | |

| 11.Balance ettlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| ↓ | |

| 12.Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Please click Presentation-Auto plastic parts and injection moul... to know more about HOWE precision mold co., ltd.

Q. When can I get the price?

A. We usually quote within 24 hours after we got your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

Q. How can I get an accurate price?

A. There are some basic specs we need to know for price calculation, that is: 3D drawings in STP, IGS, X-T format are available, Please suggest to us your quantity too.

Q. Do you accept the OEM?

A. OEM is welcome. We can custom goods according to your design.

Q. What is the shipping?

A: By express(FedEx, UPS, DHL, TNT, EMS, etc...), by Air, by shipping.

Q. How do I pay for the order?

A. The common payments are T/T(Telegraphic Transfer), western union,

Q. I have an idea for a new product, but I don't know if it can be manufactured. Can you help?

A. Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling, and likely set-up costs.

Q. What are the advantages of having my parts manufactured locally?

A. Vertex can offer quick reaction times to any changes in specification, batch size, or material. We can ship small or large quantities anywhere in Europe overnight to accommodate unforeseen changes in demand.

Q. My components have already been developed on CAD. Can you use the drawings?

A. Yes! DWG, DXF, IGES, Solidworks, and Rhino files can all be used to generate quotes, models and mould tools - this can save time and money in producing your parts.

Q. Can I test my idea/component before committing to mould tool manufacture?

A. Yes, we can use CAD drawings to make models for design and functional evaluations.

Q. What type of plastic is best for my design/component?

A. Materials selection depends on the application of your design and the environment in which it will function. We will be happy to discuss the alternatives and suggest the best material.

Q. What type of mould tool do I need?

A. Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8, or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q. Ok, I've decided to go ahead with my project. How long will it take to get my parts?

A. It can take 3-8 weeks to have the mould tool manufactured depending on the part's complexity and the number of cavity (single or multi). After we have received final approval by you of the new tool, you can expect delivery of parts within 2-3 days.

|