| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Electronic Plastic Parts |

|---|---|

| Brand Name: | HOWE |

| Model Number: | HW-063 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1000 pieces |

| Price: | negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 15000 pieces per month |

| Delivery Time: | 25-30days |

| Packaging Details: | PE bag , as customer requested |

| Moulding Parts: | Customized Auto Car Plastic Parts Accessory Plastic Mold Maker |

| Color: | black or customized |

| Tool Material: | NAK 80, S136, 2311, 2344, 8407, 2083, P20 |

| Runner: | Cold/Hot runner |

| Appearance finished: | Texture/Graning |

| Gate Type: | Submarine gate, Side / Edge gate |

| Mould Life: | 300000 to 500000 Shots |

| Machine Type: | High speed CNC, EDM, Wire Cutting |

| Mould cavity: | Single/Multi-Cavity |

| Mould Standard: | HASCO, DME, LKM, etc |

Mould Information:

| Part Material | Normal Plastic:PP,PE,EVA,PS; Engineering Plastic: ABS,PA,PA6,PA66,PC+ABS,PA46,PA+60%GF,PC,POM,PBT,TPU,TUR; High Engineering Plastic: PEEK,PPS,PPO,PEI,PES,PLA,LCP,Antistatic Plastic,etc. |

| Part Size | Customer Required |

| Part Surface | Printing,Painting,Plating,Laser, Electroplate,Frosted,Silk-screen,etc. |

| Part Color | Nature,white,black,red,yellow,blue,green, as per your requirement. |

| Product Processing for this plastic injection part | Plastic Injection--->Painting--->Packing QC 100% inspection before going on the next step |

| Appliance Filed | Auto Accessories, Electronic Products, Industrial Products, Household Products, Medical Device, Transportation, Petrochemical for this item used for the Sweeping Robot Case |

| Key technology for this plastic injection part | Mould Design, Surface Treatment |

| Equipment for our plastic injection parts | Full automatic injection machine from 50T to 300T--30 sets |

| QC Equipments | Projector, Hardness Tester, TwoThree Dimension Measuring Instrument, Abrasion Tester, Coating Thickness Tester, Color Difference Tester etc. |

| Export Market | Mainly export to Europe, North America, Australia, also to the Middle East, South America, Asia. |

| Service | OEM Service, Custom as client's drawing |

| Our principle | Take quality as the first consideration, with sincere service, low price, prompt delivery. |

| Delivery Time | 5--30 days, as per your quantity and mold cavity. |

| Payment | 30% deposit,70% before shipment |

| Packing | Normal packing or as per customer's request |

plastic material | advantage | disadvantage | industry example |

PS(Polystyrene) | Clear plastic, very moldable, inexpensive, recyclable, high

chemical resistance, high electrical resistance, heat distortion

~200°F | Cracks and breaks easily | Disposable cups, disposable applications, decorative applications,

electrical applications |

HIPS (High Impact Polystyrene) | Very moldable, relatively inexpensive | Very moldable, relatively inexpensive | Picture frames, shower walls, food containers |

ABS (Acrylonitrile Butadiene Styrene) | Engineered plastic that can be customized to desired levels of

stiffness, hardness, heat deflection, and many other

characteristics | UV sensitive – requires a UV protective cap layer for extended

exposure | UV sensitive – requires a UV protective cap layer for extended

exposure |

PVC (PolyvinylChloride) | Very high chemical resistance, stain-resistant, stiffer than ABS,

high room temp. impact strength, natural flame retardant qualities | Difficult to process | shower surrounds, moldings, kick panels, display cases |

Polycarbonate | Extremely high impact resistance, high clarity – good for

transparent parts, precision molding, good insulator, high heat

distortion point ~270°F | Low chemical resistance to certain substances (oil, gasoline, harsh

chemicals), can be difficult to process, higher material, and

processing cost | Visors, plastic guards, transportation components (headlights,

taillights, instrument panels), appliance drawers, skylights |

Polycarbonate/ABS | When compared to true polycarbonate – less expensive, lower heat

distortion ~240°F, much easier to process, higher chemical

resistance | When compared to true polycarbonate – reduced clarity, lower heat

distortion ~240°F | When compared to true polycarbonate – reduced clarity, lower heat

distortion ~240°F |

PETG (polyethylene- terephthalate) | Very easy to process, high clarity – good for transparent parts | Not UV stable – unsuitable for extended exposure | Structural automotive parts, hand tools, industrial components |

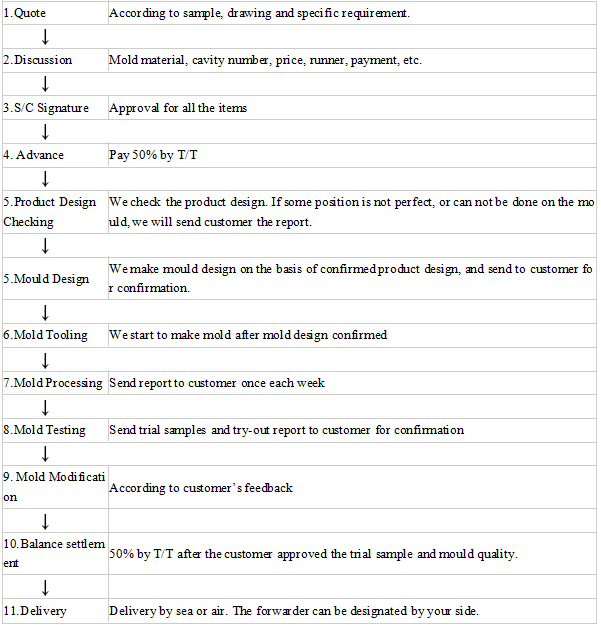

Steps:

FAQ :

Q1: How many molds can you build per year?

We can build 400-500 sets of injection molds per year.

Q2: How many percent of molds are exported?

80 percent of the molds we built are exported to the USA, Europe,

Japan, and other countries.

Q3: When did you start to export molds to the USA and Europe?

We had business with them for 8 years. So we know their standard

very well.

Q4: Can you make double color injection mold and over mold?

Yes, we can.

Q5: Can you make insert mold?

Yes, we can, we are good at insert molds, too. we have more

experience in insert molds.

Q6: Can you make a multi-cavity mold?

Yes, we built some of the molds with 18,72,97 cavities.

Our Services

1. we can produce any plastic injection and die casting mold, and it depends on the customer's requirement.

2. we know the quality is the soul of the enterprise, and we have

the power to make a high-quality product. We always have good

cooperation relations with every client.

we have rich experience in plastic Injection mold(plastic Injection

molding), Die casting mold(die-casting molding), Our products

mainly support for several fields as below:

1.Automobile

2.Electronic

3.Mechanical

4.Household

5.Medical

|