| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Auto Plastic Parts |

|---|---|

| Brand Name: | OEM/ODM |

| Model Number: | HW-011 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | negotiable |

| Payment Terms: | T/T |

| Supply Ability: | more than 30 sets per month |

| Delivery Time: | 25-35days |

| Packaging Details: | vacuum bag, then wooden box , as customer requested |

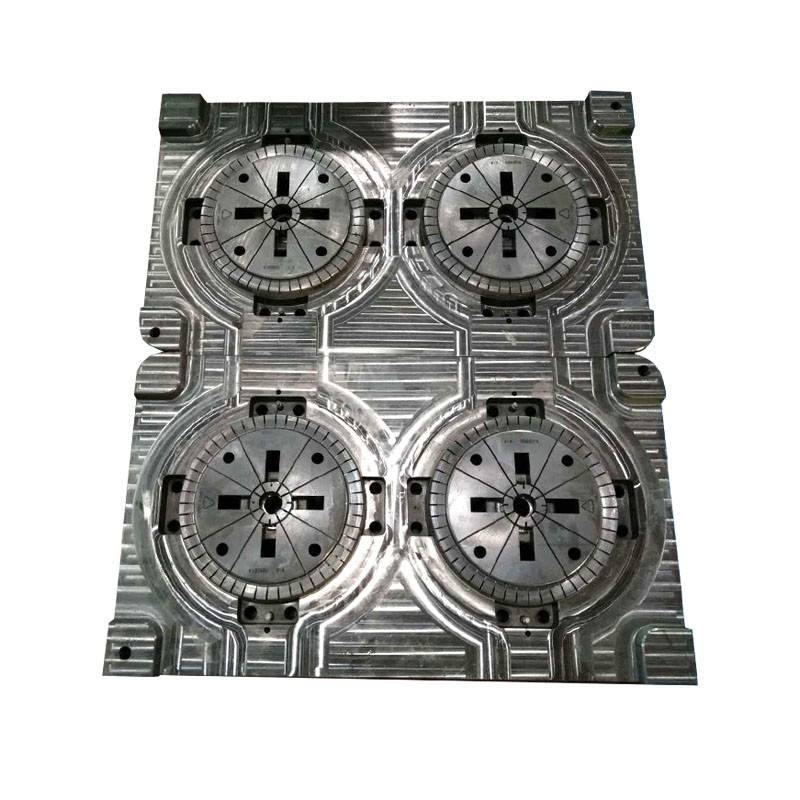

| Plastic Tooling: | Automotive Plastic Injection Molding |

| Ejection system: | Stripper plate,Lifter,Push Bar,Ejection Pin etc |

| Eletronic Shell: | PP,PC,PE,ABS,PVC etc. |

| Core&Cavity Material: | 718H, P20,NAK80,2316, 2738,S136 |

| Appearance finished: | Mirror Polishing,Texture/Graning |

| logo: | Silk screen,laser engraving,sandblasting |

| Quality equipment: | 2D/3D coordinate measuring tester |

| Mould Life: | 500000~1000000 Shots |

| Cavity No.: | Single/Multi |

| Runner: | Hot runner/cold runner |

Mould Information:

| Product name | High-quality OEM medical parts plastic injection mould |

| Mould cavity | Based on samples |

| Mould base material | S50C, P20.73H8, 718H, H13, NAK80, S136, etc |

| Material of mold core | P20, 718H, 738H, H13, 420, etc |

| Cavity No. | Single or multi |

| Runner | Hot runner/cold runner |

| Mould size | Based on sample |

| Mould structure | Automatic knockout, self-lock |

| Mould lifetime | 100,000 shot times |

| Lead time | 20-25days |

| Packing terms | Wooden case |

| Export country | Europe countries, the USA, Britain, etc |

| Guarantee | Advanced mold design technology, high precision CNC strictly QC & QE, to ensure high quality of molds. |

Plastic Mold (Mould) production process:

1. 3d Design/Samples for quotation: According to 3D drawing or samples for quotation.

2. Negotiations: Including the price of molds, molds sizes, material for cores & cavities, weight of the product, product color, payment, molds lifetime, delivery, etc.

3. Purchasing Order: After the customer confirming the mold design and quotation.

4. Making mold(mould): Confirm drawing, start to do DFM, mold flows and mold detail agreed with the customer, start production.

5. Production schedule: Every week we will feedback to the customer about the mold progress(picture).

6. Sample shoot: We provide the molds test samples for confirmation(about 10-15 pieces), we will start mass production when getting your signature samples.

1. Capacity of Research and Development

HW has a powerful team for research and development, which is

capable of manufacturing the injection and die-casting molds with

one cavity to Multi- cavities. At the same time, we can manufacture

perform molds especially according to customers' injection molding

machines. We also have the service to manufacture the products by

the molds, such as electronic enclosures, junction boxes, tool

case, equipment case, plastic parts,etc..

2. Advanced Processing Equipment

Many machine tools are imported from America and Japan, such as

Machine center, CNC lathers, EDM and so on. All of these increases

processing precision, good interchangeability, and low eccentricity

3. Perfect Inspection Method.

Inspection tools include projector, hardness tester, stress tester,

eccentric tester, electric balance, and other inspection tools.

The screw neck is made and inspected strictly by the standard of

Coca-cola and the screw neck has been up to the standard of

Coca-cola.

4. After-Sales Service

Technologists professional in after-sales line and excellent credit

assures stable operation of the machines.

| Item Name | Expert of Precision Injection Plastic Tooling Design and Mold Maker |

| Service | 1.CNC Plastic/Metal Prototypes |

| 2.Vacuum casting/vacuum forming(Silicon Mould) | |

| 3.Low Volume Production | |

| 4.Rapid Hardware/Sheet Metal Prototypes | |

| 5.CNC Aluminum/Brass/Copper/Bronze CNC machining/machined parts | |

| 6.Automotive and medical equipment Prototypes | |

| 7.SLA/SLS prototype | |

| 8.Metal Stamping&NCT Stamping | |

| 9.3D Printing | |

| 10.Die-casting, hardware machining | |

| 11.Electronic Manufacturing Service | |

| 12.Injection mould&Plastic Injection | |

| 13. Lathing parts | |

| 14.Design service (OEM service) | |

| Certification passed | Bureau Veritas, ROHS, ISO |

|