| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Screw Air Compressor |

|---|---|

| Brand Name: | Shanghai Rotorcomp |

| Model Number: | LGFD screw compressor |

| Certification: | ISO.TUV,CE,GS |

| Place of Origin: | Germany |

| MOQ: | Min.:1set |

| Price: | Negotiable |

| Payment Terms: | Western Union, T/T, L/C, D/P, D/A |

| Supply Ability: | 3,000 sets/per month |

| Delivery Time: | 15-20 working days |

| Packaging Details: | Exported Wooden Package |

| Warranty: | 5 Years |

| Air End: | Made in Germany |

| Design: | Design in Germany |

| Motor: | IP55 super high efficient motor |

| cooling system: | increased 30% cooling performance |

| Rated Power: | 45Kw/60Hp |

| Working Pressure: | 7-15Bar |

| Weight: | 1280Kg |

| Dimension: | 1500*1000*1380mm |

| Company Info. |

| Shanghai Rotorcomp Screw Compressor Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

1. World-leading Made in Germany Rotorcomp screw air end

2. 5 years warranty

3. Extraordinary cooling system design

4. Intelligent control system

5. higher efficient energy-saving motor in IP55 IE3 CE&MEPS,

SF1.2

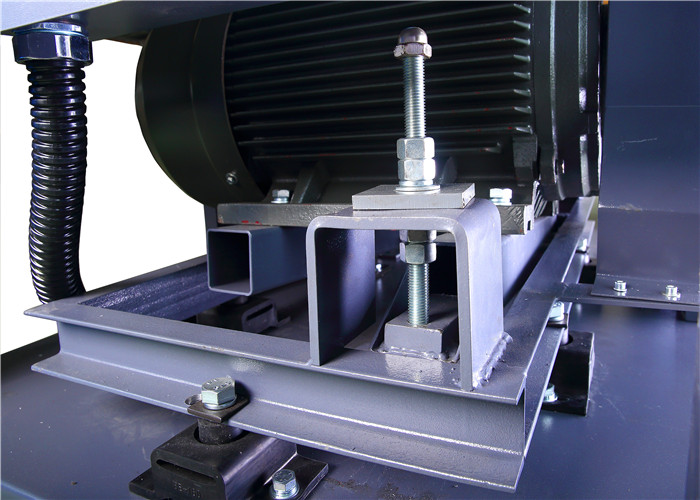

6. Unique driving guard system

7. ISO,TUV,GA,SGS certificates

Advantages of our new EVO-technology

New ROLLING PROFILE- ultimate efficiency with

reduced noise

Long life cycle due to increased bearing dimensions

and wear-free ROLLING PROFILE

Wide operating pressure range from 5 to 15 barg

High quality manufacturing and assembling

Made in Germany

Quality assurance ?bench test of every air end

before leaving our factory

Easy application selection with our new

ROTORCOMP SIZING AIR software

Highest flexibility for your package design

Suitable for all types of drive driving motors

Drive options: Belt drive, direct drive, internal gear drive

Base and face-flange mounting

All the electronic components are brand products of leading

manufacturers. rives and electrics. The Air end of our LGFD rotary

screw compressor-made in Germany. The centrepiece of the compressor

is the air end, which is constructed and manufactured with the most

modern production methods in Germany. The optimal air end for your

compressor can be used on a modulating basis. In

frequency-controlled units, where the operating pressure changes,

adjustments can also be made on the frequency controller to

optimally adjust the speed of the compressor to the compressor

performance.

The working process of the worm compressor: the motor transmits the

power to the worm shaft by a coupling or a belt, and the worm

drives the star gear to move relatively in the worm groove, the

volume of the closed element changes, the gas, the conveying

compression, when the design is reached The pressure value is

discharged into the oil separator by a symmetrical triangular

exhaust port on the left and right sides of the main body casing.

45KW air cooling compressor parameters

| ITEM | UNIT | MODEL | ||||

| LGFD-45 | ||||||

| Free air delivery | m3/min | 7.60 | 7.0 | 5.8 | 5.0 | |

| Max. working pressure | MPa | 0.8 | 1.0 | 1.3 | 1.5 | |

| Compressor type | Oil inject screw compressor | |||||

| Cooling type | Air cooling | |||||

| Driven type | Belt driven | |||||

| Inlet status | Temperature | ℃ | ≤55 | |||

| Pressure | MPa | Atmospheric pressure | ||||

| Relative humidity | ≤90% | |||||

| Noise Level | dB(A) | ≤72 | ||||

| Residual oil content | ppm | ≤1 | ||||

| Drive rotor speed | rpm | 5500 | 5000 | 4450 | 4000 | |

| Compressed air outlet temperature | ℃ | Ambient temperature+10 | ||||

| Cooling air flow | m3/hr | 10200 | ||||

| Control mode | Intelligent controller | |||||

| Safety valve set pressure | MPa | 0.88 | 1.10 | 1.43 | 1.60 | |

| Lubricating oil volume | L | 30 | ||||

| Lubricating oil brand | ROTORCOMP | |||||

| Compressed air outlet connection | G1-1/4 | |||||

| Dimension | L | mm | 1500 | |||

| W | mm | 1000 | ||||

| H | mm | 1320 | ||||

| Net Weight | kg | 1280 | ||||

| Motor | Model | Y2200L1-2 | ||||

| Speed | rpm | 2950 | ||||

| Rated Power | KW | 45 | ||||

| Service factor | 1.2 | |||||

| Protection type | IP55 | |||||

| Insulation class | F | |||||

| Startup mode | ʏ-Δ starting | |||||

| Voltage | V | 380(Special on request) | ||||

| Frequency | Hz | 50(Special on request) | ||||

| Rated current | A | 84 | ||||

| Weight of motor | kg | 312 | ||||

| Note: |

| 1. The above parameters and color are designed according to customer needs, the parameters are for reference only, the final parameters of the drawings shall prevail; |

| 2. According to user requirements and needs, to join way: air/water cooling, oil content, weight, appearance size according to the need to design, to the final order and the technical agreement shall prevail; |

3. Frequency converters (optional). 4. 1 years warranty, 5 years warranty for air end |

|