| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Non Precious Dental Alloys |

|---|---|

| Brand Name: | Willett |

| Model Number: | CF-s |

| Place of Origin: | China |

| MOQ: | 25kg |

| Price: | Contact for pricing |

| Payment Terms: | Western Union, L/C, T/T |

| Supply Ability: | 100 + kg + per day |

| Delivery Time: | 5-8 working days |

| Packaging Details: | bottle or paper box |

| Density: | 8.5g/cm3 |

| Elongation: | 5% |

| Melting range: | 1250-1300C |

| Vickers hardness: | 360HV10 |

| Co: | 60% |

| Cr: | 31% |

| Mo: | 5.6% |

| Modulus of elasticity: | 190GPa |

| Company Info. |

| Success Dental Company |

| View Contact Details |

| Product List |

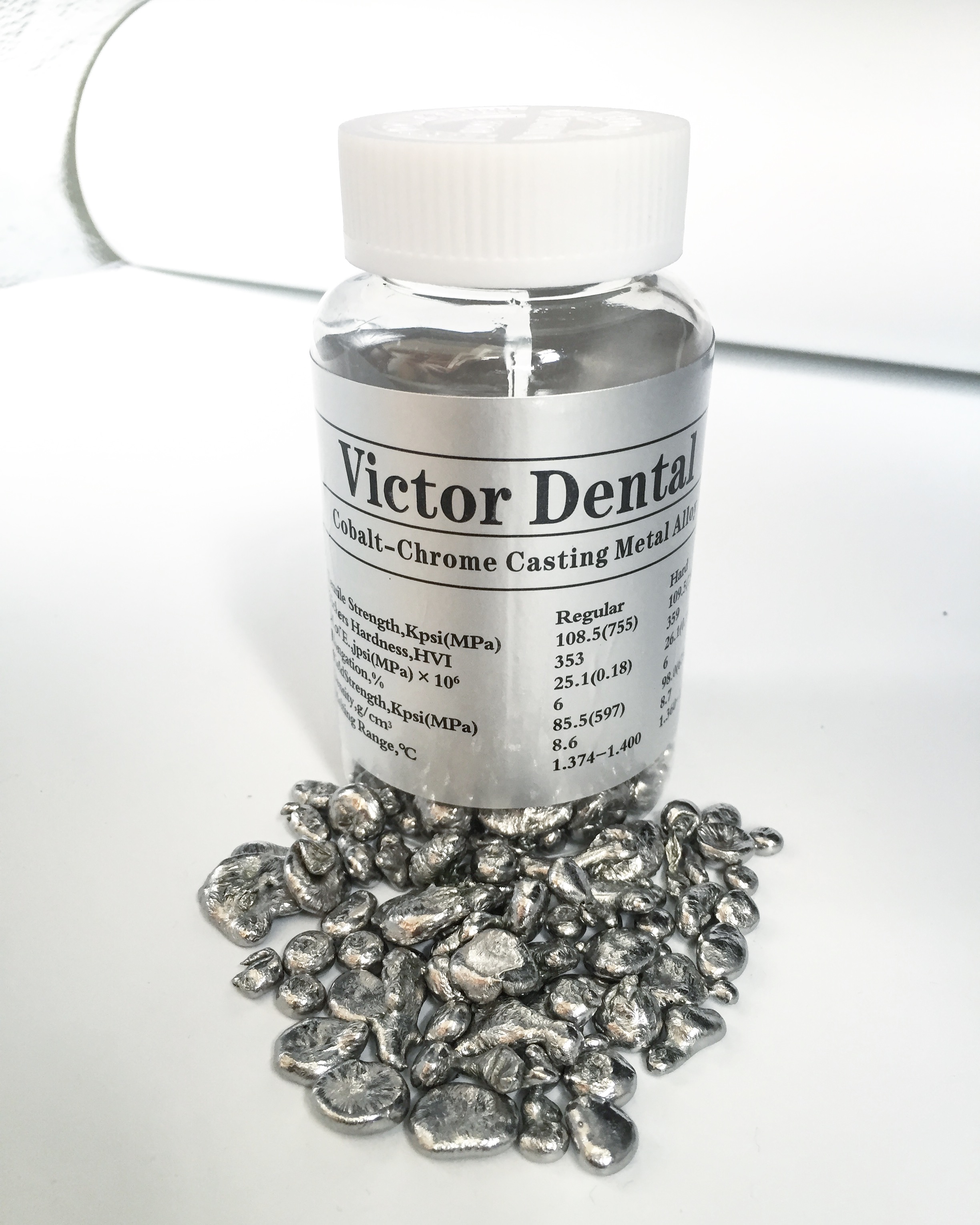

Dental Non Precious Dental Alloys made with Cobalt Chrome for framework in shot shape

With or without label in irregular shapes

Advantages:

(1). Superior mechanical performance castability, toughness

(2). Corrosion resistance , wear resistance , high intensity , high hardness, stays in shape

(3). Nickle-free & beryllium-free, great biocompatibility

Properties:

Melting Point: 1250-1300 ℃

Density : 8.5g/cm3

Hardness: 360HV10

Modulus of elasticity: 190GPa

Elongation: 5%

Composition:

| Co | Cr | Mo | W | Others |

| 60-63 | 27-29 | 5-6 | 4-6 | ≤0.5 |

FAQ:

What is the perfect temperature to obtain the best result when casting?

The casting temperature should always maintain 100~150℃ higher than liquidus temperature.

What is the perfect timing to obtain the best result when casting?

While casting Nickel Chrome alloys that don't contain Beryllium, the surface of the melting alloys will appear a layer of shadow. Once the shadow disappears and the edges of the alloy have become rounded (melted until it becomes a sphere shape is not necessary) will be the best timing for casting. Perfect timing for casting Cobalt Chrome alloy is to heat it till the surface membrane perforated and a spark of bright light start to appear.

Cobalt Chrome casting piece is incomplete, what are the causes?

1. Casting ring is not heated evenly: While casting Cobalt alloys, casting ring must heat up gradually and slowly before reaches 300℃. Let it sit in the oven in between 300℃ and 600℃ for 10-30 minutes. Once it heats up to the desired temperature, maintain the same temperature for at least 30 minutes before casting.

2. Casting temperature is below/above alloy's requirement.

3. Strub designed improperly: For example, Strub is too narrow. We strongly recommend the Strub diameter consist of 5mm or more.

4. The amount of alloy is not enough for the casting piece or the centrifugal force of casting pressure is not enough.

5. Casting piece has not avoided the heat center.

|