| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Low Pressure Die Casting Parts |

|---|---|

| Brand Name: | Rongbao |

| Model Number: | OEM |

| Certification: | ISO9001 |

| Place of Origin: | Xi'an China |

| MOQ: | 100 |

| Price: | $1-500 |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 100000 |

| Delivery Time: | 4 weeks |

| Packaging Details: | Carton and Wood |

| Product Name: | Low Pressure Die Casting Parts |

| Material: | A380 |

| Casting Weight: | 9.85KG |

| Casting Process: | Low pressure die casting |

| Standards: | ASTM |

| Dimension Tolerance: | CT8 |

Low Pressure Die Casting, Metal smelting and preparation of molds or molds, preparation before pouring, Demoulding.

Robot Arm Aluminum Casting is aluminum arm, Hydraulic and electric

Product Introduction

NOTICE:All the products on our website indicate the ranges we can manufacture and our production capability.

We offer cast aluminum products according to customer’s drawings or samples.

Please feel free to contact us if you have any questions or suggestions about our business.

Product Specification

| Dimension Tolerance | CT8 |

| Surface Roughness | Ra6.3-12 |

| Manufacture | OEM/ODM |

| Certificate | ISO9001:2015 |

| Standard | ASTM, DIN,JIS, EN, ISO, GB |

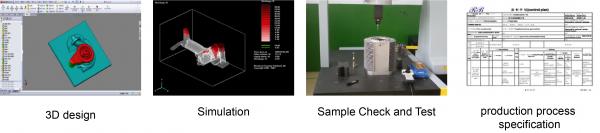

| Software | Pro/E,UG, Solidworks, Auto CAD, PDF |

| Material | A356, A380, aluminum alloy or according to your requirements |

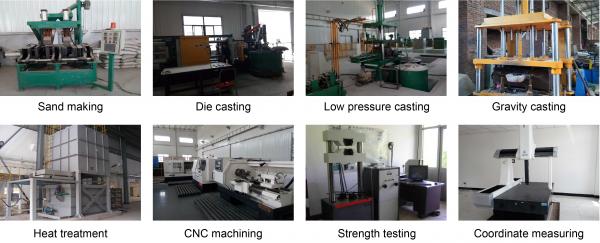

| Machining | CNC turning, milling, drilling, grinding, cutting, reaming and threading |

| Service | Sand casting, die casting, low pressure die casting, Gravity casting and CNC Machining |

| Testing facility | Spectrometer, Tensile test machine, Hardness test machine, CMM (Coordinate Measuring Machine) |

| Finished | Polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, Chrome plating, mirror polishing. |

| Product | All kinds of aluminum casting parts |

Quality Control

Casting Process

Packaging & Delivery

Our Customers

Office & Factory

Production Equipment

Additional Product Information

The essence of high pressure casting (die casting) is under the effect of high pressure, the liquid or semi-liquid metal with high speed filling type die casting die casting mould cavity, and molding and solidification under pressure casting method. Pressure casting, high - pressure and high - speed filling die - casting two major characteristics. Its commonly used piezometric pressure ranges from thousands to tens of thousands of kPa, even up to 2 x 105kPa. The filling speed is about 10~50m/s, and in some cases it can reach 100m/s or more. The filling time is very short, generally within the range of 0.01~0.2s.

Compared with other casting methods, die casting has the following three advantages:

High quality casting dimension precision; Good surface finish, generally equivalent to 5~8 levels; The strength and hardness are high, and the strength is generally 25~30% higher than that of sand casting, but the elongation is about 70% lower. Stable size and good interchangeability; Die casting thin - walled complex casting. High efficiency machine productivity high, such as domestic J Ⅲ type 3 horizontal cold empty die casting machine die casting of 600 ~ 600 times on average eight hours, small hot chamber die casting machine die casting of 3000 ~ 3000 times on average every eight hours. Die casting die - casting die - casting die - casting die - casting die - casting clock alloy, life up to hundreds of thousands, even millions of times; Easy to implement mechanization and automation. Good economic effect due to the precision size of die casting pieces, surface gloss and other advantages. Generally, it is no longer used for machining and is used directly, or the amount of processing is small, so it not only improves the utilization rate of metal, but also reduces a lot of processing equipment and working hours. Easy casting price; Other metals or non-metallic materials may be used in combination die-casting. It saves both assembling time and metal.

|