| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Cable Tray Roll Forming Machine |

|---|---|

| Brand Name: | BOSJ |

| Model Number: | BOSJ-C |

| Certification: | ISO,CE,SGS |

| Place of Origin: | JIANGSU |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union, D/A, D/P |

| Supply Ability: | 60 Sets Per Year |

| Delivery Time: | 50-60 working days |

| Packaging Details: | Suitable Size Container for Machine |

| Production Amount: | 8-15m/min |

| Roller Material: | Cr12 |

| PLC System: | MITSUBISHI,SIEMENS |

| Thickness: | 1.2-2.0mm |

| Machine Type: | Full Automatic |

| Function: | Cable Tray,trunking system |

| Spare Parts: | Punching mould |

| Operation Type: | PLC Interface |

| Driven type: | Gearbox |

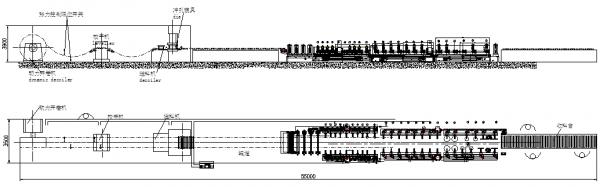

Automatic Galvanized Steel Cable Tray Cold Roll Forming Machine

Normal Cable Tray Sizes

| No. | Width/mm | Height/mm | Thickness/mm | Length/mm |

| 1 | 150-600 | 50-150 | 0.8-1.5 | Any length |

Cable Tray Roll Forming Machine

| No. | Name | Type and size | Quantity | (KW) Power(kw) |

| 1 | De-coiler | 1 set | ||

| 2 | Straightener | 1 set | 4 | |

| 3 | Servo-feeder | 1 set | 4 | |

| 4 | Punching Press | YANGLI GROUP | 1 set | 25 |

| 5 | Punching Mould | 1 set | ||

| 6 | Conveying Table | 1 set | ||

| 7 | Roll Forming machine | Full automatic control type | 1 set | 15 |

| 8 | Collection table | 1set | ||

| 9 | Electric Control System | 1 set | 7.5 |

1, Equipment capabilities

It can according to the need to produce the steel width (60mm≤§≤860mm), many kinds of specification electric cable bridges and other structure product.

Product speed by punching: 2.55m/min

Continuous rollforming speed: 10-15m/min

Material thickness: 1~2mm

Material require: Q235 cold roll steel

Production line has automatic and manual two operating mode, may realize the linkage and the partition revolution work.

2, Main composition of machine

This unit consists of the decoiler, ML-900 flatting, 200 punch, die, servo feeding, guider, main roll forming machine, follow cutting, cut-to-length part, recoiler, electrical control cabinet; etc.

3.Cable tray roll forming machine uses cantilever type at the two sides, the punch press do the round ribs in bottom or different holes’stamping and cutting. The material is guided into main roll forming machine by guider. By electrical control, automatically improve and adjust different width and height.

Automatic inner tight decoiler | ◊ coil inner diameter 450mm-550mm ◊ maximum width of coiling600mm ◊ maximum weight of loading 2500kg |

Main forming machine | ◊ a. number of forming steps 11rows ◊ material of shaft 45# steel . Outer diameter 60mm ◊ main motor power: 5.5kw ◊ The speed of forming: 0-50m/min |

Hydraulic cutter | ◊ material of blade:Cr12 mould steel with quenched treatment 60-62 ◊ cutting system :adopt advanced hydraulic drive, after forming automatic cut, no distort, no wasting , high safe factor.(tracking cutting) |

The electrical control system | ◊ The Brand of display: DELTA ◊ The main computer (PLC): DELTA DVP14 |

Hydraulic system | ◊ Adopting advanced hydraulic system of Tai Wan ◊ Power:3kw |

The equipments coating , package | ◊ the coating adopt international general shade-guide ◊ The package :simple waterproof package |

4,Machine Parameter

| NO. | Project | Unit | Parameter | Remark | |

1 | Material | Type | High strength steel | ||

| Strength of material sheet | Map | ≥350 | |||

| Thickness of material sheet | mm | 1.2~2.0 | |||

| 2 | Size of production | mm | Reference the picture | ||

| 3 | Production speed | m/min | Punching speed 4m/min Forming speed 10m/min | ||

| 4 | Material of roller | GCr15 quenching treatment | |||

| 5 | Drive type | Gear | |||

| 6 | Power | kw | About 75 | ||

| 7 | Electric control system | PLC variable frequency control | |||

| 8 | Dimensions(Length*width*height) | m | 55X4X3.9 | ||

Service from BOSJ

BOSJ offer engineers to install and commision the machines at buyer's factory,and also train your workers to operate the machine.

Guarantee: one year after finishing machine installation and commission at buyers' factory.

24 hours response time

a) Mechnical engineering team with 10 actual working experience

b)Electrical engineering team with 10 actual working experience

|