| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | High Carbon Alloy Steel |

|---|---|

| Brand Name: | CF Steel |

| Model Number: | 1.2344 / H13 / SKD61 |

| Certification: | ISO / Mill Certificate |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000 Mt/Month |

| Delivery Time: | 10-15 work days |

| Packaging Details: | Standard export packing or according to customers' requirement. |

| Grade: | 1.2344 / H13 / SKD61 |

| Shape: | Steel plate / Round bar / Flat bar |

| Heat treatment: | Annealed / Q+T |

| Test: | SGS/Ut 100%/Element testing |

| Certificate: | ISO / Mill Certificate |

| Payment Term: | 30% Deposit, Balance by L/C at Sigth After Shipment |

Hot Work Plastic Mould High Carbon Alloy Steel Plate DIN 1.2344

♦ Introduction:

Grade 1.2344 / H13 / SKD61 is kind of pressuer resistance mold steel.

After electroslag remelting, this steel has the characteristic of uniform texture, good hardenability, excellent machining performance and polishing performance.

It also has the characteristic of high toughness and plasticity, good wear resistance of high and low temperature and high temperature fatigue resistance and heat resistance.

♦ Equivalent grades:

| GB | DIN | AISI | JIS | ASSAB |

| 4Cr5MoSiV1 | 1.2344 | H13 | SKD61 | 8407 |

♦ Available size (mm):

| Flat Bar Size(mm) | Round bar Size(mm) | |||

| Thickness | Width | Length | Diameter | Length |

| 16-260 | 205-610 | 3000-6000 | 16-200 | 300-6000 |

♦ Features:

1, Electro slag remelting, annealing with diffusion process and

ultrafining heat-treatment has good microstructual homogeneity and

finer dispersed carbides.

2, High isotropy, aspect rations≥0.8.

3, Good tempering performance, high toughness, high temperature

strength, good thermal stability and thermal fatigue resistance.

4, Annealing hardness≤230HB,quenching hardness 51-55HRC,tempering

hardness 46-50HRC.

♦ Chemical Composition(%):

| C | Si | Mn | P | S | Cr | Mo | V |

| 0.32-0.45 | 0.80-1.20 | 0.20-0.50 | ≤0.030 | ≤0.030 | 4.75-5.50 | 1.10-1.75 | 0.80-1.20 |

♦ Applications:

1, Used to make forging die, hot extrusion die, precision forging

die, die for aluminium, copper and its alloy mould.

2, Applicable to hot work, aluminum, magnesium, zinc, copper alloy

die-casting die, cutting groove knife, scissors and hot forging

action, plastic mold, hot work reamer, rolling knife, general hot

forging die, hot bolt mold, heat, all kinds of tools, etc.

♦ Recommend heat treatment:

| Quenching | Tempering | ||||||

| Heating temperature/℃ | Cooling way | Hardness (HRC) | Tempering temperature /ºC | Tempering number | Hardness (HRC) | ||

| First preheating | Second preheating | Last heating | |||||

| 500-600 | 820-860 | 1010-1040 | Oil Cooling | 53-55 | 560-620 | 2 | 50-46 |

♦ Factory Hardness:

Annealing 235 ~ 205 HB, quenching ≥50 HRC

♦ Technical service:

Die vacuum heat treatment and die surface treatment(N-O,C-N,carburize and nitridation surface treatment).

♦ Terms of payment:

30% deposit T/T and the balance by L/C at sight, or T/T.

♦ Delivery condition:

EF or ESR, Hot rolled or forged, black surface or milling.

For abundant stock, 15-20 days.For customized products, 30-50 days.

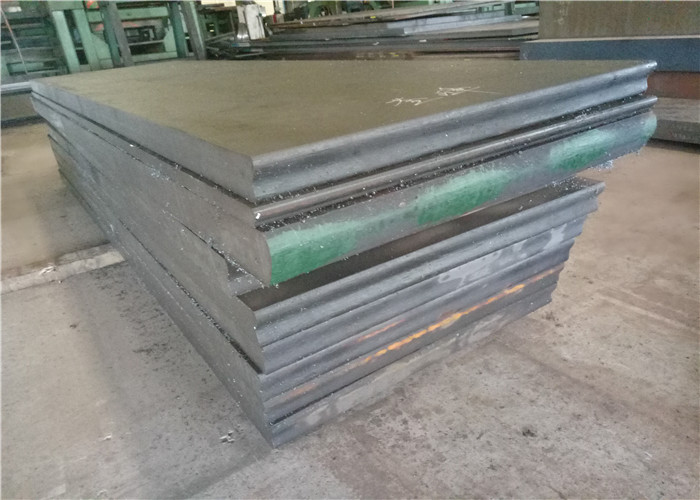

♦ Product photos:

|