| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

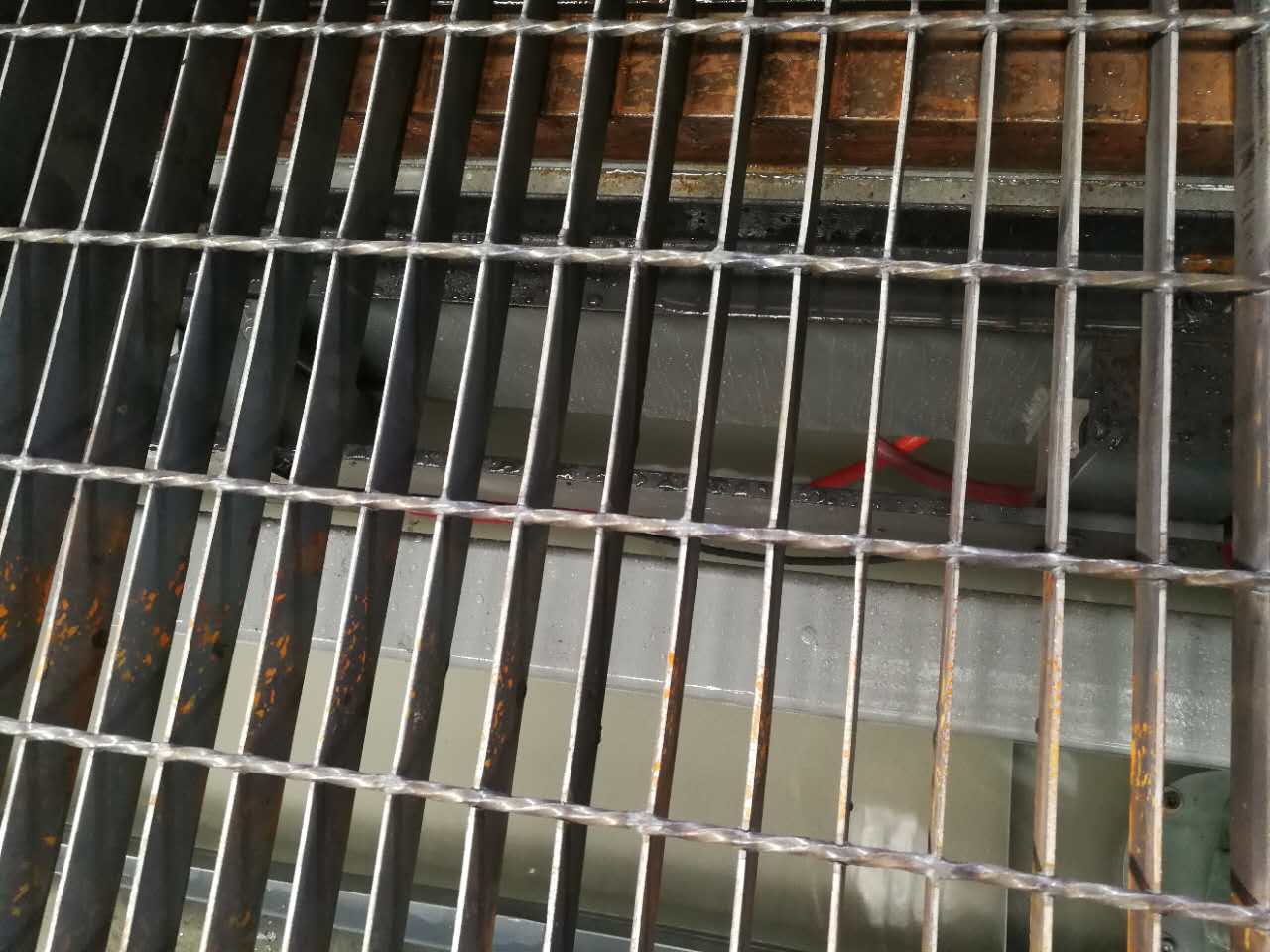

| Categories | Steel Grating Welding Machine |

|---|---|

| Brand Name: | MLG |

| Model Number: | MLG-1200 |

| Certification: | CE |

| Place of Origin: | Hebei China |

| MOQ: | One set |

| Supply Ability: | 4--5 sets per month |

| Delivery Time: | 40 days after receiving deposit or L/C. |

| Packaging Details: | Wooden pallet and the plastic package in the container. |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Product name: | Steel grating welding machine |

| Rated power: | 250KVA |

| Bearing flat bar: | 2.5*25--6*65mm |

| Cross bar: | 5*5--8*8mm |

| Width of mesh: | Max 1200mm |

| Transformer: | 250KVA*2 |

| Pitch of flat bar: | 25--60mm |

| Production: | 100 square meter/ 8 hours |

Japan Mitsubishi PLC Steel Bar Grating Mesh Welding Machine For Stair Trend

Product description

1. Adopts Japan Mitsubishi PLC program and touch screen to control.

2. This machine adopts hydraulic device to control welding

electrode; it can weld 3 points per time when flat bar thickness is 2.5-3mm, weld 2 points per time when flat bar thickness is 3-5mm.weld 1point per time when flat bar thickness is 5-6mm.

3. The mesh pulling system adopts Japan Mitsubishi Panasonic servo motor, more stable, high precision.

4. This machine adopts specially designed mold to fix flat bars.

The flat bar space is fixed, flat bar thickness and width can be

adjusted within range on one mold.

5. The welding transformers 250KVA with water cooling type.

Technical parameter

| Bearing flat bar | 2.5*25-6*65mm |

| Cross bar | 5*5-8*8mm |

| Grating width | Max1.2m |

| Grating length | Max.6m |

| Pitch of flat bar : | 25-60mm |

| Pitch of cross bar: | 50-200mm |

| Needed power | Min.160kva |

| Production Capacity | 30-100M2/shift (8hours ) |

| Welding transformer | 250kva*2pcs |

| Overall size: | 16*2.5*1.5M |

| Weight : | 4000kg |

Applications;

Application scope is extremely broad, general factory, workshop,

mining, port, warehouse construction of all kinds of platforms are

optional, beautiful style, convenient installation, is a kind of

new building products upgrading.It can add welding kick board (edge

board), decorative plate protector, installation fittings and other

accessories.It can be used with flat steel plates with different

specifications, or with edges, such as Angle steel, channel steel

and square pipe.You can also install handles and hinges on a steel

plate that needs to be moved or opened frequently.

|