| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | bench grinder brushes |

|---|---|

| Brand Name: | HAWK or OEM |

| Model Number: | bench wire wheel 300mm |

| Certification: | MPA EN 1083-2 |

| Place of Origin: | China |

| MOQ: | 500~3000PCS |

| Price: | USD4~12/pc |

| Supply Ability: | 100K PCS per month |

| Delivery Time: | 6weeks |

| Packaging Details: | 10pcs/master carton 0.04cbm/ctn |

| Material: | steel wire dia 0.2mm |

| cup color: | red or customized |

| MSFS RPM: | 3000 |

| face width: | 30mm |

| Trim length: | 60mm |

| pad printing: | available |

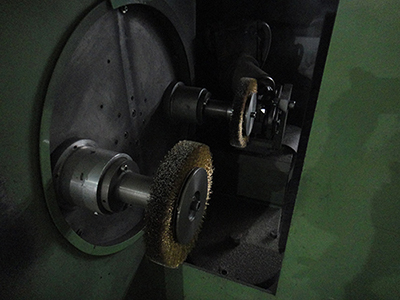

Top quality Hawk 300mm Crimped bench wire wheel brush

0.008'' brass coated steel wire,

arbor hole 32mm, with adapters

Out diameter:300mm

Face width:30mm

Trim length: 60mm

Shape: circular

Application: for bench grinders

medium to heavy brush applications;

added choice of adapters to fit most popular spindle diameters.

remove carbon,rust,welding scale,rust burrs and spatter etc.

| Item No. | Product Description | Wire dia. | Arbor hole/thread |

| 587 042-3008 | Bench grinder brush, diameter 300mm,brass coated wire 0.20mm,crimped,arbor hole 32mm,R 120mm, thickness 30mm, trim 60mm | 0.2mm | arbor hole 32mm,R 120mm |

| 587 062-3008 | Bench grinder brush, diameter 300mm,brass coated wire 0.30mm,crimped,arbor hole 32mm,R 120mm, thickness 30mm, trim 60mm | 0.3mm | arbor hole 32mm,R 120mm |

| 587 077-3008 | Bench grinder brush, diameter 300mm,brass coated wire 0.38mm,crimped,arbor hole 32mm,R 120mm, thickness 30mm, trim 60mm | 0.38mm | arbor hole 32mm,R 120mm |

| 587 043-3008 | Bench grinder brush, diameter 300mm,brass coated wire 0.20mm,crimped,arbor hole 32mm,R 120mm, thickness 42mm, trim 60mm | 0.2mm | arbor hole 32mm,R 120mm |

| 587 063-3008 | Bench grinder brush, diameter 300mm,brass coated wire 0.30mm,crimped,arbor hole 32mm,R 120mm, thickness 42mm, trim 60mm | 0.3mm | arbor hole 32mm,R 120mm |

| 587 073-3008 | Bench grinder brush, diameter 300mm,brass coated wire 0.38mm,crimped,arbor hole 32mm,R 120mm, thickness 42mm, trim 60mm | 0.38mm | arbor hole 32mm,R 120mm |

for OEM dimensions, pls further contact for technical support.

abrasive testing:

brush is made to undergo extreme speeding test.

rotation balance detection:

each brush is examined on rotation balance machine to make sure they arrive at customer's hand under qualified balance performance.

power brush wearing test:

storage

|