| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Bottle Blow Molding Machine |

|---|---|

| Brand Name: | Eceng |

| Model Number: | YCQ-2L-4 |

| Certification: | CE&ISO&SGS |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 10 sets per Month |

| Delivery Time: | 30 workingdays |

| Packaging Details: | Film pack |

| Material: | pet preform |

| Cylinder: | SMC |

| Color: | Orange |

| Electric parts: | Schneider |

| PLC: | Mitsubishi |

| Weight: | 3.5Ton |

1.The machine adopts human`computer interface to control the whole

working procedures, auto`loading, auto blowing, auto dropping.

Action cylinders are all assembled with magnetic induction

switches.Connect with PLC to control every step and test every

cylinder. Next action will continue after the former step done, If

former step is not finished, alarm automatically and do not work.

PLC displays problem position.

2.Fast speed, accurate position, smooth action.

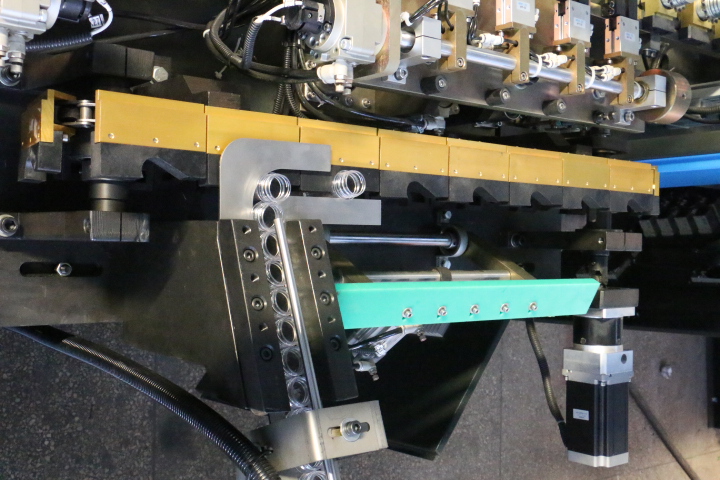

3.According to special demand, adopt cross double crank pressed

clamping, with strong clamping force. Mould open stroke can be

adjustableaccording to the bottle size to save the time.

4.Far infrared heater lamps have strong penetrations , preforms are

heated uniformly while rotating, PLC or electronic pressure

adjustor controls each group of temperature separately.

5.Particular pre`heater design makes prefrom close while heating.

Change space, shorten heating tunnel and reduce energy consumption

according to the bottle size while blowing.

6.The air supply system consists of slight blow, high pressure

blow, low pressure actions, to supply enough air for different

products.

7.Special recycling installation for high pressure air reduce the

energy consumption.

8.Shifting servo motor is more accurate and faster.

9.Connecting rod automatic lubrication oil device protects the

machine well.

10.Production workmanship process is fully automatic to make best

quality and pollution`free. it holds less investment, high

efficiency, easy operation, simple repair, safety etc.

ITEM | UNIT | YCQ-2L-4E | |

PRODUCT | Theoretical output | Pcs/h | 5500 |

Max. Volume | L | 1.5 | |

Max. height | mm | 360 | |

Max. diameter | mm | 105 | |

MOULD | Number of cavities | / | 4 |

Mould plate dimension (L*H) | mm | 600*360 | |

Mould thickness | mm | 188 | |

Mould opening stroke | mm | 110 | |

ELECTRICAL | Power | 220-380V/50-60Hz | |

Total Power | KW | 25 | |

Heating Power | KW | 22 | |

AIR SYSTEM | Operation Pressure | Mpa | 0.8-1.0 |

Action Air Consuming | m3/min | ≥1.6 | |

Blowing Pressure | Mpa | 2.6-4.0 | |

Blowing Air Consuming | m3/min | ≥4.8 | |

MACHINE | Main body dimension (L*W*H) | M | 3.4*1.9*2.05 |

Main body weight | KG | 2600 | |

Preform Autoloader (L*W*H) | M | 1.9*1.9*2.2 | |

Preform Autoloder weight | KG | 200 |

|