| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

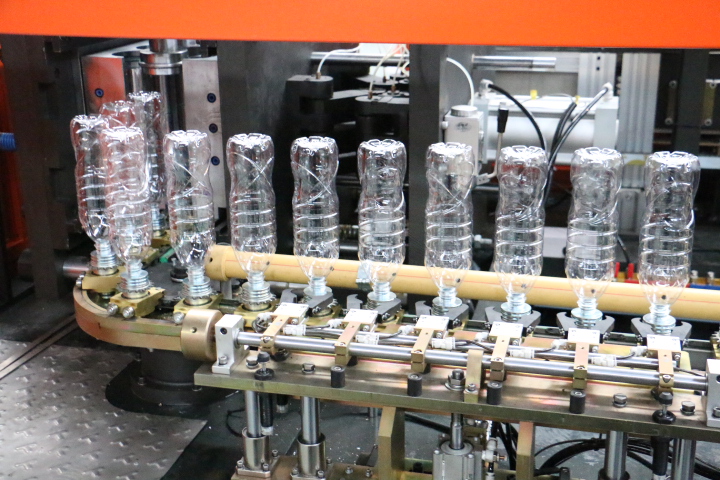

| Categories | PET Bottle Blowing Machine |

|---|---|

| Brand Name: | Eceng |

| Model Number: | Q9000 |

| Certification: | CE&ISO&SGS |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 10 sets per month |

| Delivery Time: | 30 working days |

| Packaging Details: | Film pack |

| cavity: | 6 |

| capacity: | 9000 |

| PLC: | Mitsubishi |

| Cylinder: | SMC |

| color: | orange |

| Electric parts: | Schneider |

| What is technical parameter of our water making machine plastic? |

Bottle type specification | cavity | 6 |

| theory output (PCS/HR) | 9000 | |

| Max. volume (L) | 2L | |

| Bottle mouth maximum overall diameter (mm) | 28-38mm | |

| Bottle biggest diameter | 100mm | |

| Bottle maximum height | 330mm | |

Power specifications | Light tube quantity | 32pcs |

| Light tube power | 1.25kw | |

| Maximum heating power | 40kw | |

| All electric machine installation | 43kw | |

| Actual consumption | 30.1kw | |

Air pressure specification | Work pressure | 7-9kg/cm2 |

| Low-pressure gas consumption | 1600Ltr/min | |

| Blow bottle pressure | 25-35kg/cm2 | |

| Higher -pressure gas consumption | 4000 Ltr/min | |

Frozen water specification | Work pressure | 5-6 kg/cm2 |

| Temperature range | 10 | |

| Consumption | 8000kcal/hr | |

| Frozen water flow | 88Ltr/min | |

Machine specification | Size of the machine | 6.5x1.5x1.9 (m) |

| Weight of the machine | 4ton |

| What is the feature for our water making machine plastic? |

| What is the parts of our water making machine plastic? |

| Pneumatic part | valve | SMC |

| cylinder | ||

| Electric part | PLC | SIEMENS |

| Operating system | SIEMENS | |

| Relay | OMRON | |

| Infrared thermometer | America raytek | |

| servo motor | Schneider |

Sample and Mold

| How about our after-sale service ? |

Provide whole drawing for the perform mould and bottle mould. Free charge for word design on the mould. We can help you

install the machine; from setting machine, testing, and to check the machine is on the good working condition. There is a litter

charge, only for flight charge and accommodation.

Warranty:

We response for one year warranty for the machine, however, it without any human conduct. And provide one-year free

spare part for client.

Up 15 million shots for the bottle mould.

3 million shots for the perform mould, cap mould.

All moulds are designed by CAD/CAM.

We also can provide the drawing for the mould, help you to maintain the mould, and machine.

|