| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Paper Slitting Machine |

|---|---|

| Brand Name: | LangO |

| Model Number: | GFQ-1300B |

| Certification: | CE ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 set |

| Payment Terms: | T/T |

| Model: | GFQ-1300B |

| Thickness of Material: | 0.012-0.15mm |

| Mechanical speed: | 380mm |

| Unwinding Diameter: | 3” & 6” Φ700mm |

| Max. unwinding width: | 1300mm |

| Width of final roll: | 50-1300mm |

| Rewinding diameter: | 3”Φ148mm |

| Deviation-rectifying method: | Photocell track / Edge track |

| Price: | Negotiation |

| Delivery Time: | 15-30days |

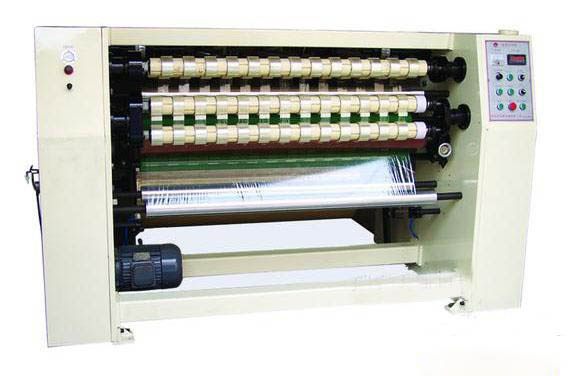

High Speed Paper Slitting Machine / Paper Slitter Rewinder Machine 0.012mm - 0.15mm

Specifications:

Main Technical Variables

| Type | GFQ-1300B |

| Thickness of Material | 0.012-0.15mm |

| Mechanical speed | 380mm |

| Unwinding Diameter | 3” & 6” Φ700mm |

| Max. unwinding width | 1300mm |

| Width of final roll | 50-1300mm |

| Rewinding diameter | 3”Φ148mm |

| Deviation-rectifying method | Photocell track / Edge track |

| Automatic Tension control method | Invariable tension/ Variational tension |

| Total power | 15kw |

| Weight of machine | 3.6T |

| Overall dimension | 3050×1950×1650mm |

Description:

Performance and Features:

1. The whole machine is controlled by PLC system. It can set

working parameters via touch screen as per the slitting

requirement. LCD screen display and monitor the working status. The

control system has the function such as start buffer, loose proof

and meter counter etc, and it is very easy for operation.

2. Introduce Automatic Tension Control System for unwinding to keep

the unwinding tension constant. It is also can be controlled by

taper control according to slitting requirement. Introduce Japanese

MITSUHASHI LPC photoelectric automatic alignment system for Edge

Position Control. Track Edge or Track Line automatically ensures

the correct position of the running material.

3. Shaft less Pneumatic Clutch for Unwinding Roll Loading and

Hydraulic Pressure Lift Utility (Option)

4. Main drive and rewinding section is driven by two vector control

motors separately. Rewinding tension is controlled by PLC system

according to the preset parameters and rewinding diameter as per

slitting requirement. The control method is automatic digital

taper.

5. The rewinding roller is air differential shaft (Goldenrod, or

similar). Slip force can be adjusted automatically to accommodate

thickness variety of the material for multi-roller slitting.

Applications:

Suitable for BOPP, PET, PVC, PE, aluminum foil and paper material

etc. slitting and rewinding.

It integrates advanced mechanical, electric, optical and pneumatic

technology and components.

This machine has been proved to be of high performance such as high

speed, high stability,

easy operation and high slitting neatness. It is a kind of ideal

machine for slitting.

Competitive Advantage:

- High Speed

- Low price

- Stable quality

- labor cost saved

- maintainers easily

Why choose us?

1. We are the famous science and technology professional enterprise

specialized in researching, developing, manufacturing and selling

of Bag Making Machines, Paper Bag Making Machine, Film Blowing

Machine, Side Weld Bag Making Machine, Paper Slitting Machine, Non

Woven Bag Making Machine, Side Sealing Bag Making Machine,

Flexographic Printing Machine, Gravure Printing Machine, Paper Cup

Making Machine, Tissue Paper Making Machine, Automatic Bag Making

Machine, Carry Bag Making Machine, with best quality control, best service .

2. 100% QC inspection and debugging Before Shipment.

3. 100% rest assured after-sales service.

Our service

Pre-Sales Service:

According to your need of actual situation and budget, our

professional sales team will provide professional consultation and best solution with strong technical support.(such as raw paper purchasing suggestion, jumbo roll dimension needed, packing ways for transportation, suitable machine and processing craft recommendation with detailed explanation especially in embossing and lamination, etc.)

After-Sales Service:

1. We also provide the door to door abroad installation, equipment debugging, technical training service;

2. Warranty:1 year quality assurance

3. Building customer files, solving various technical problems for

user;

4. Our technical team give you 100% rest assured global presence service even over the warranty period.

|