| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Film Blowing Machine |

|---|---|

| Brand Name: | LangO |

| Model Number: | SJ-M45 SJ-M50 |

| Certification: | CE ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 set |

| Payment Terms: | T/T |

| Model: | SJ-M45 SJ-M50 |

| Screw Diameter: | 45mm 50mm |

| Max. Folding Width Of Film: | 100-450mm 100-550mm |

| Single-side Thickness Of Film: | 0.01-0.10mm |

| Max. Output: | 25-30kg/h 30-35kg/h |

| Screw Ratio L/D: | 28:1 |

| Haul-off Motor Power: | 1.1kw |

| Heating Power: | 11kw 13kw |

| Price: | Negotiation |

| Delivery Time: | 15-30days |

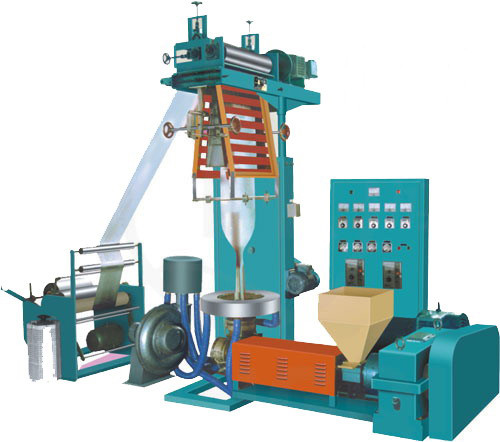

Double Purpose HDPE Plastic Film Blowing Machine 30Kg - 35Kg / H Output

Specifications:

| Model | SJ-M45 | SJ-M50 |

| Screw Diameter | 45mm | 50mm |

| Max. Folding Width Of Film | 100-450mm | 100-550mm |

| Single-side Thickness Of Film | 0.01-0.10mm | 0.01-0.10mm |

| Max. Output | 25-30kg/h | 30-35kg/h |

| Screw Ratio L/D | 28:1 | 28:1 |

| Main Motor Power | 7.5kw | 11kw |

| Haul-off Motor Power | 1.1kw | 1.1kw |

| Heating Power | 11kw | 13kw |

| Overall Dimension(L×W×H) | 2200×1400×2800mm | 2300×1400×3200mm |

| Weight | 1.3T | 1.4T |

Description:

The cylinders and the screw stems of the above extruders are made of high-quality alloy steel with optimum hardness and strong corrosion resistance after revision finishing and nitrogen treatment. The auxiliary machine has a platform working table for making operation easy. The coiling unit adopts torque motor to keep proper tension and make rolling even and roll-changing easy.

Applications:

The machine set is used for blowing low-density polyethylene (LDPE) and high-density polyethylene (HDPE) plastic film to make various vest bags and flat-rim bags which have been widely used for packing in the garment industry, textile industry, and food industry, etc.

Competitive Advantage:

- High Speed

- Low price

- Stable quality

- labor cost saved

- maintainers easily

Why choose us?

1. We are the famous science and technology professional enterprise

specialized in researching, developing, manufacturing and selling

of Bag Making Machines, Paper Bag Making Machine, Film Blowing

Machine, Side Weld Bag Making Machine, Paper Slitting Machine, Non

Woven Bag Making Machine, Side Sealing Bag Making Machine,

Flexographic Printing Machine, Gravure Printing Machine, Paper Cup

Making Machine, Tissue Paper Making Machine, Automatic Bag Making

Machine, Carry Bag Making Machine, with best quality control, best service .

2. 100% QC inspection and debugging Before Shipment.

3. 100% rest assured after-sales service.

Our service

Pre-Sales Service:

According to your need of actual situation and budget, our

professional sales team will provide professional consultation and best solution with strong technical support.(such as raw paper purchasing suggestion, jumbo roll dimension needed, packing ways for transportation, suitable machine and processing craft recommendation with detailed explanation especially in embossing and lamination, etc.)

After-Sales Service:

1. We also provide the door to door abroad installation, equipment debugging, technical training service;

2. Warranty:1 year quality assurance

3. Building customer files, solving various technical problems for

user;

4. Our technical team give you 100% rest assured global presence service even over the warranty period.

|