| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Side Sealing Bag Making Machine |

|---|---|

| Brand Name: | LangO |

| Model Number: | LO-400UZB |

| Certification: | CE ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 set |

| Payment Terms: | T/T |

| Model: | LO-400UZB |

| Feeding driving AC motor: | 1.0kw × 2=2.0kw |

| Upper lower driving AC motor: | 2.2kw × 1=2.2kw |

| Warping traction motor: | 0.75kw × 1=0.75kw |

| Side heat seal device: | 4.0kw × 3=12.0kw |

| Lateral heat seal device: | 4.0 × 3=12.0kw |

| Total: | Approx:35kw |

| Gax pressure: | 0.6MPa |

| Cooling water: | Approx:15L/min |

| Price: | Negotiation |

| Delivery Time: | 15-30days |

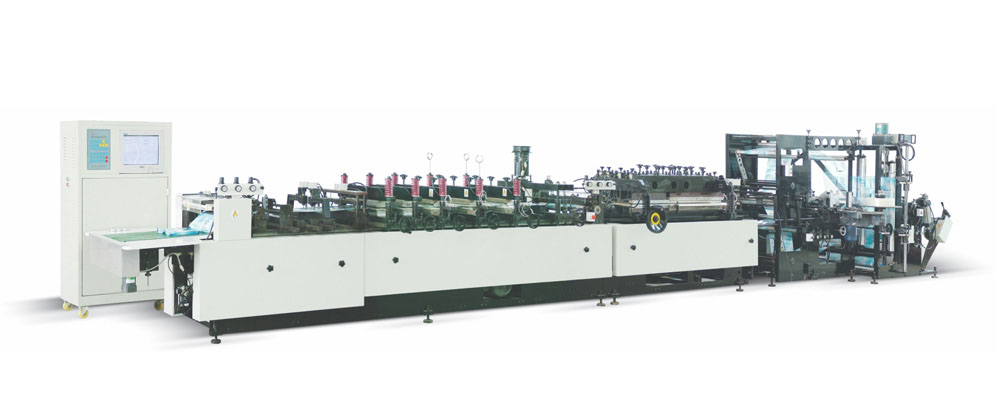

0.6MPa Gax Pressure Plastic Bag Sealing Machine / Bag Maker Machine 9000×1400×1750 mm

Specifications:

Electricity-use configuration

| Feeding driving AC motor | 1.0kw × 2=2.0kw |

| Upper lower driving AC motor | 2.2kw × 1=2.2kw |

| Warping traction motor | 0.75kw × 1=0.75kw |

| Side heat seal device | 4.0kw × 3=12.0kw |

| Lateral heat seal device | 4.0 × 3=12.0kw |

| Control system and others | 3kw |

| Total | Approx:35kw |

| Gax pressure | 0.6MPa |

| Cooling water | Approx:15L/min |

| Dimension(L×W×H) | 9000×1400×1750mm |

| Gross weight of equipment | Approx:4000kg |

Description:

ADAPTABILITY

Bagging speed: 150parts/min(mechanical design speed),approx.40m/min

Bagging width: Max width 400mm

Bagging length: 50-1920mm When the set program is above 320mm, it

will automatically change into multiple conveyances.

WARPING MODE

Fabrication: put the warp beam horizontally,with V fold support,and

pneumati-cally lock.

Control: tension is automatically controlled by swimming

roller,magnetic powder brake.displacement sensor etc.

DRIVING MODE

Feeding traction: driven by AC servomotor

Upper lower sealing press: driven by AC servomotor.

FUNCTIONS

Temperature: 0-300℃,contact control,CRT displaying.

Automatic count: presetting is available

Punching device: time can be preset; contiuous or interval punching

is available.

Working mode: printing.non-printing.

Mode of multiple conveyances: twice to six times conveyance.(Air

piston)

Measurement for length: distance between color scales can be

measured photoelectrcally.

Message alert: lost of photoelectricity,lost of

temperature,servo-motor alalrm and auto-switch off the machine.

Applications:

APPLICATION SCOPE

Material: Various compound films

Roll folding: max width 850mm.max diameter 600mm.

Competitive Advantage:

- High Speed

- Low price

- Stable quality

- labor cost saved

- maintainers easily

Why choose us?

1. We are the famous science and technology professional enterprise

specialized in researching, developing, manufacturing and selling

of Bag Making Machines, Paper Bag Making Machine, Film Blowing

Machine, Side Weld Bag Making Machine, Paper Slitting Machine, Non

Woven Bag Making Machine, Side Sealing Bag Making Machine,

Flexographic Printing Machine, Gravure Printing Machine, Paper Cup

Making Machine, Tissue Paper Making Machine, Automatic Bag Making

Machine, Carry Bag Making Machine, with best quality control, best service .

2. 100% QC inspection and debugging Before Shipment.

3. 100% rest assured after-sales service.

Our service

Pre-Sales Service:

According to your need of actual situation and budget, our

professional sales team will provide professional consultation and best solution with strong technical support.(such as raw paper purchasing suggestion, jumbo roll dimension needed, packing ways for transportation, suitable machine and processing craft recommendation with detailed explanation especially in embossing and lamination, etc.)

After-Sales Service:

1. We also provide the door to door abroad installation, equipment debugging, technical training service;

2. Warranty:1 year quality assurance

3. Building customer files, solving various technical problems for

user;

4. Our technical team give you 100% rest assured global presence service even over the warranty period.

|