| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Axle Shaft Forging |

|---|---|

| Brand Name: | HUIXUAN |

| Model Number: | 30T |

| Certification: | ISO9001:2008,TÜV,(BV),(LR),ABS,RINA,(GL),(KR),(DNV),(NK),PED |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 2000-4000 Ton/Month |

| Delivery Time: | 15-50 days |

| Packaging Details: | Poly wood case, wood pallet, steel frame support |

| application: | machinery parts |

| size: | as drawing |

| material: | steel |

| Forging ratio: | ≥3.5 |

| Melting process: | EF+LF+VD |

| heating treatment: | N+T Q+T |

| Company Info. |

| JIANGSU HUI XUAN NEW ENERGY EQUIPMENT CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

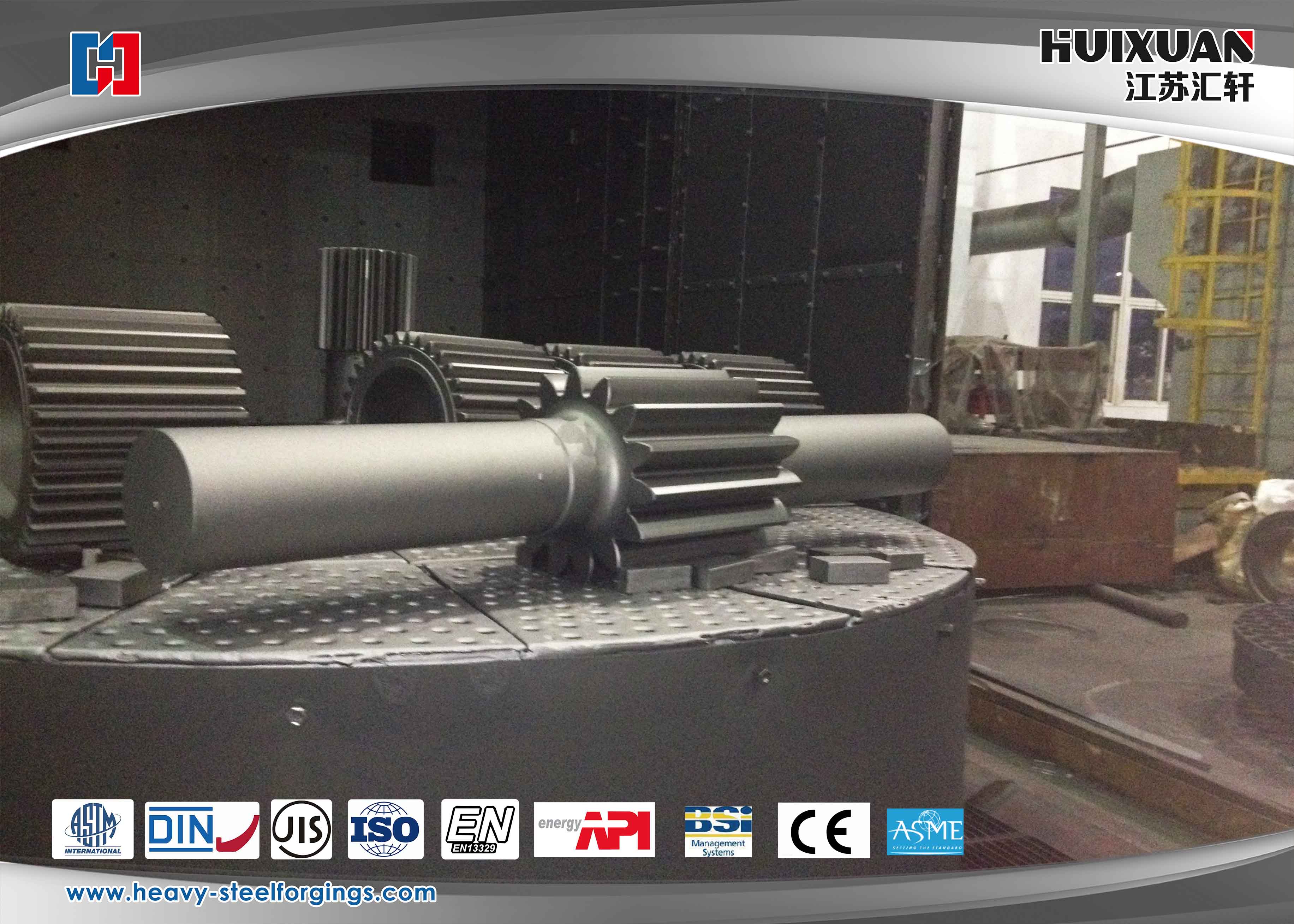

Alloy Steel Axle Shaft Forging ASME Standard Heavy Duty Gear Shaft

Products:

Alloy steel gear shaft,heavy duty gear shaft,axis,Q+T steel gear shaft,precision gear shaft

Products reference:

| Material | 4340,20CrMnMo,34CrNiMo7-6,18CrNiMo7-6 |

Forging Equipment | 4000T Open die hydropress |

| Applications | Gear box transmission components,close fit,transfer force between gear shaft |

Melting process | EF+LF+VD |

Production process | Forging+heat treatment+rough machining+(Q+T)+hobbing+gear grinding+finish machining |

Forging ratio | ≥3.5 |

Applicable standard | ASTM,ASME,DIN,JIS,ISO,BS,API,EN |

Executive standard | JB/GB/EN/DIN/JIS/ASME/ASTM/ISO |

Certification authority | ISO9001:2008,TÜV(BV),(LR),ABS,RINA,(GL),(KR),(DNV)(NK),PED. |

Delivery terms | Rough machining(N+T);Finish machining(Q+T),nitriding quenching |

Test equipmnets | Spectrograph,UT device,tensile and compact test machine,metalloscope,outside micrometer,bore dial indicator,trilinear coordinates measuring instructment Hardness test machine. |

Service | Our service included the forging, process, heat treatment, finish machining, package, local logistics, customers clearance and maritime transport. We took the customer’s requirements as the principal thing, and pay attention on the products quality. |

Custom properties

Material elements | C | Si | Mn | P | S | Cr | Ni | Mo | |

| 20CrMnMo | 0.17-0.23 | 0.17-0.37 | 0.90-1.20 | 0.035 | 0.035 | 1.10-1.40 | 0.30 | 0.20-0.30 | 0.17-0.23 |

| 34CrNiMo6 | 0.30-0.38 | ≤0.040 | 0.50-0.80 | ≤0.035 | ≤0.035 | 1.30-1.70 | 1.30-1.70 | 0.15-0.30 | |

| 18CrNiMo7-6 | 0.15-0.21 | 0.17-0.35 | 0.50-0.90 | ≤0.025 | ≤0.025 | 1.50-1.80 | 1.40-1.70 | 0.25-0.35 | |

| 4340 | 0.38-0.43 | 0.15-0.35 | 0.60-0.80 | ≤0.035 | ≤0.040 | 0.70-0.90 | 1.65-2.00 | 0.20-0.30 | - |

Mechanical properties | Dia.(mm) | TS/Rm(Mpa) | YS/Rp0.2(Mpa) | EL/A5(%) | RA/Z(%) | Type Of notch | Impact energy | HBW |

| 20CrMnMo | Ø15 | ≥1180 | ≥885 | ≥10 | ≥45 | V | ≥55 | ≤217HBS |

| 34CrNiMo6 | Ø15 | 750-900 | 450-600 | ≥13 | ≥55 | V | -40℃≥20 | ≤269HBS |

| 18CrNiMo7-6 | Ø15 | ≥980 | ≥785 | ≥9 | ≥40 | V | ≥47 | ≤269HBS |

| 4340 | Ø15 | ≥980 | ≥835 | ≥12 | ≥55 | V | ≥78 | ≤179HBS |

Process procedure:

Forging process flow quality control: Raw material steel ingot into warehouse(test the chemical content) → Cutting→ Heating(Furnace temperture test) → Heat treatment after forging(Furnace temperture test) Discharge the furnace(blank inspection)→ Machining→ Inspection(UT,MT,Visal diamention, hardness)→ QT→ Inspection(UT, mechanical properties, hardness, grain size)→ Finish machining→ Inspection (dimension)→ Packing and Marking(steel stamp, mark)→ Storage Shipment

Commerce clause

| Max weight | 30T |

| MOQ | 1PC |

| Delivery time | 30-50 days |

| Package | Poly wood case, wood pallet, steel frame support |

| Delivery terms | FOB;CIF;CFR;DDU; |

| Payment terms | T/T,LC |

| Transportation | ocean,air |

Keywords

Gear Shaft is the mechanical parts that can support rotation compoments,and rotate together to transfer movements,torque or bending moment,Alloy steel after heat treatment,nitriding quenching treatment to reach the gear strength,precision gear shaft after gear grinding to reach the accuracy requirements,trilinear coordinate measuring machine to check accuracy.

Advantage

|