| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Tool Inspection System |

|---|---|

| Brand Name: | UNIMETRO |

| Model Number: | RANGER 600 |

| Place of Origin: | China |

| MOQ: | 1 |

| Payment Terms: | T/T |

| Supply Ability: | 5 per month |

| Delivery Time: | 15 work days |

| Packaging Details: | Wood case |

| Price: | Discussible |

| Certification: | CE,ISO |

| Product Name: | 5M HD Camera Tool Inspect System for Flat End Milling Cutter |

| X axis travel: | 80mm |

| Y axis travel: | 60mm |

| Z axis travel: | 60mm |

| Max tool diameter: | 20mm |

| Max tool length: | 200mm |

| Working distance: | 90mm |

| Company Info. |

| Unimetro Precision Machinery Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

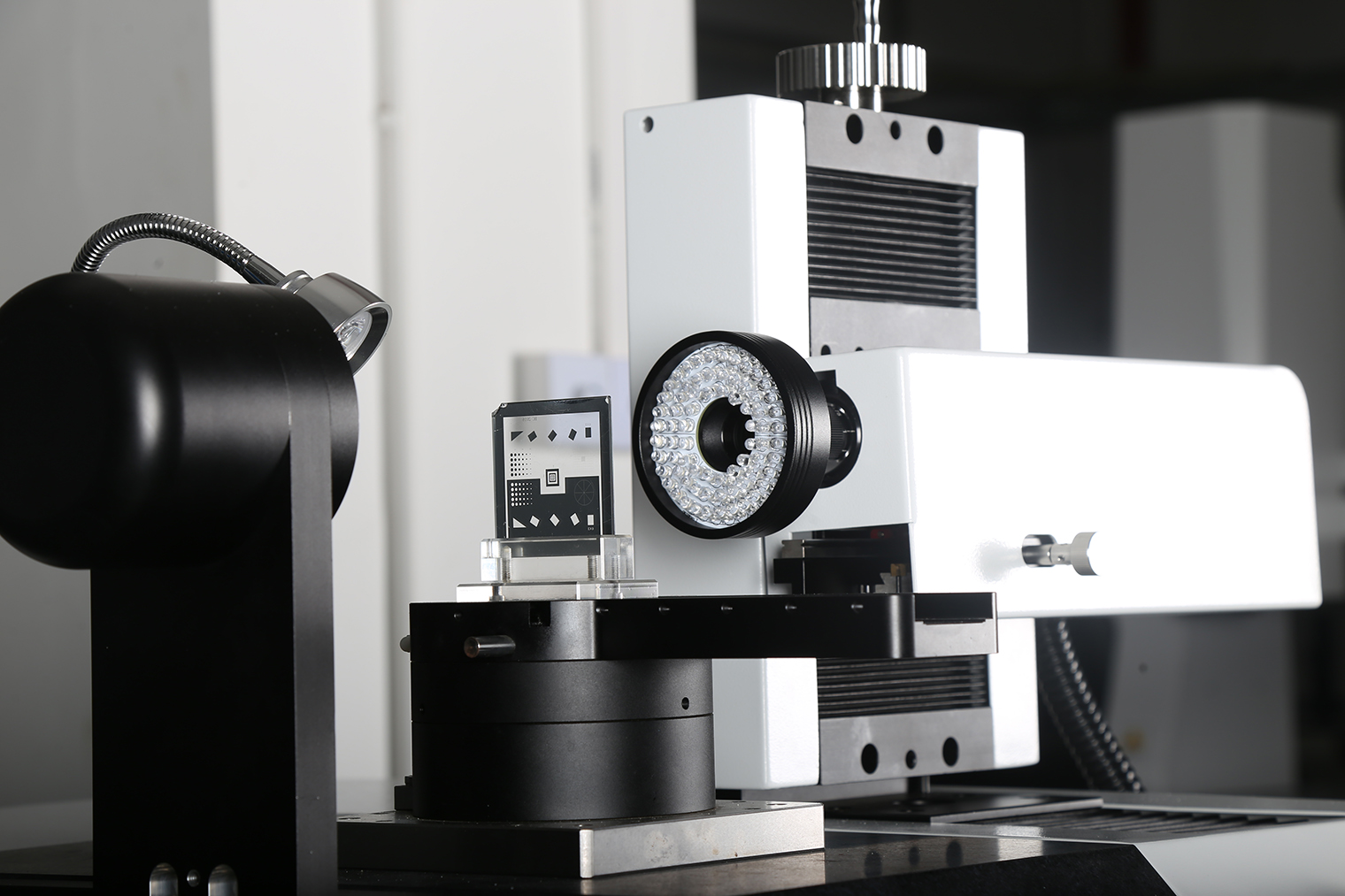

The UNIMETRO RANGER600 Tool Inspection System is the universal

measuring machine for drills, milling cutters and counters and

countersinks under a Flexible illuminating system. Thanks to the

compact design and great stability, the RANGER600 can be employed

in the metrology room, receiving inspection, or directly in

production.

Parameters

| Product name | Multi-Function Tool Inspection Machine For Different Shape Cutting Tools | |||||

| Model | Ranger 600 | |||||

| X axis travel | 80mm | |||||

| Y axis travel | 60mm | |||||

| Z axis measuring range | 60mm | |||||

| Max tool diameter | 20mm (optional 30mm) | |||||

| Max tool length | 200mm (optional 350mm) | |||||

| Working distance | 90mm | |||||

Lens | 0.7X-4.5X dented zoom lens | |||||

Camera | 5MP HD camera | |||||

Linear scale resolution | 0.1um | |||||

Magnification | 12.6X-79.2X/25.2X-158.4X(optional) | |||||

Field of vision | 27*20mm-43*33mm/13.5*10mm-2.3*1.6mm (Optional) | |||||

Accuracy | X ~ Y, (2.5 + L / 100)μm , L is the measured length | |||||

PC | Windows 10 OS, with 24" LCD monitor | |||||

Illumination system | 8 sections LED ring light, contour light and flexible auxiliary light, all software control and programmable. | |||||

Input format | DXF files | |||||

Output format | EXCEL, DXF | |||||

Features

1. Advanced Design

﹥Ergonomic design and solid construction.

﹥HD image capturing and display combination, also microscope

magnification level is optional.

﹥Stable and accurate V block for easy tools holding and alignment.

﹥Mechanical fixed measuring angles of 0 degrees and 90 degrees are

available on the rotary stage.

﹥High accuracy encoder is embedded in the rotary table, offers

precise angle location for users.

﹥Multiple section programmable LED ring light for surface

illumination, also including contour lighting and free angle

auxiliary light for standard features.

﹥SMARTOOL measuring software offers specific measuring function for

cutting tools.

﹥Automatic edge detection, fast angle measurement with reticle, CAD

element comparison functions are available.

2. Multiple Angles Measuring

For a more fast and precise tools angle location during the

measuring process, the rotary table of the RANGER600 offers 2

mechanical fixed angles, 0 degree and 90 degrees. At the 0 degree

position users are able to measure Tool End, Tool End - Center

shaft, Tool End - front angle, etc. And 90 degrees position is

available for Helix angle, Axial Front angle, First Rear angle,

Second Rear angle and Tilting Edge angle, etc.

Company Information

Our Client&Agent

| FAQ |

|---|

improved a lot on some breakable parts. You can rest assured of our product quality. |

|