| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Carbon Fiber Plate |

|---|---|

| Model Number: | TM_600mm_1000mm _2.5mm |

| Place of Origin: | China |

| MOQ: | 1-10pcs |

| Payment Terms: | T/T, PayPal,Western Union , L/C |

| Supply Ability: | 1500pcs month |

| Delivery Time: | 7 working days after receiving Order Payment |

| Packaging Details: | Normal Corrugated Carton Packing for International Shipment |

| Tool Supplies: | Cutting |

| Use: | Vehicles & Remote Control Toys |

| tolerance: | ±0.1mm |

| Technical: | Hot Rolled |

| Inspection: | Hydraulic testing, Eddy current |

| Diameter: | 600mm * 1000mm |

| Company Info. |

| SHANGHAI LIJIN IMP.&EXP. CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

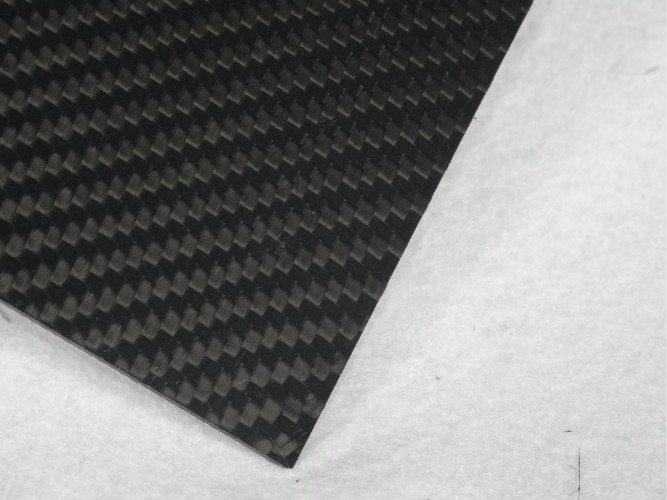

Twill Matte 2.5mm with Carbon Fiber Plate and corrosion resistance .

Introduction

This carbon fiber plate unidirectional plate is layered up so that all carbon fibers run in 0° direction

(parallel to the long direction) of the part. It is used to add stiffness to almost any material: fiberglass,

foam, balsa wood, etc. The plate can be used for a variety of applications such as aircraft and rocket

fuselages, surfboards, boat centerboards, guitar necks, etc.

One side of the laminate has been purposely roughened to facilitate

bonding to the surface. If bonding

on both sides is required, the smooth side should be roughened up with sandpaper.

Carbon filaments are often made from the oxidation and thermal pyrolysis of polyacrylonitrile material.

Polyacrylonitrile is a acrylonitrile-based polymer used in the creation of some synthetic materials.

Polyacrylonitrile molecules are made of long chains which are aligned by drawing continuous filaments.

When these chains are heated under the correct conditions they bond side to side forming ladder

polymers. Narrow graphene sheets are formed which merge together to make a single round filament.

This product is approximately 94-95% carbon. Instead of polyacrylonitrile, pitch or rayon can also be

used although this produces a lower-quality fiber. If the carbon is heat treated in the range of 1500-3000 degrees celcius, the fiber can become

a higher strength, higher molulus product.

The highest tensile strength (>800,000 psi) can be created by

heating the fiber between 1500 and 2000

degrees. The highest modulus of elasticity (77,000,000 psi) can be obtained by heating the fiber material

from 2500 degrees to 3000 degrees. This balance between strength and elasticity is what allows a carbon

fiber hood to be so strong but also so durable. Carbon fiber density is about 1740 kg/m3. The three kinds

of carbon fiber are standard modulus, intermediate modulus and high modulus. Tensile strength tends to

vary between 2000 MPa and 7000 MPa. Rayon used to be a more popular precursor for carbon fibers

and is still used on some applications like rockets. However, it is not much more common for PAN or even

pitch to be used. The fiber yarns can be processed in many ways.

Specification

Length mm | Weave | Finish | Material Type |

600*1000 | Twill | Matte | Full Carbon Fiber |

Display

|