| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Stud And Track Roll Forming Machine |

|---|---|

| Brand Name: | Sussman |

| Model Number: | SM-ST |

| Certification: | CE ISO 9001 |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | negotiable |

| Payment Terms: | L/C, T/T, |

| Supply Ability: | 5sets per month |

| Delivery Time: | 60days |

| Packaging Details: | standard packing with steel wire fixed and film coated |

| Material: | Galvanized steel or Customers' requirement |

| material thickness: | 0.3-1.2mm |

| Roller material: | GCr15 Steel with quenching |

| Drive: | Chain transmission |

| Forming speed: | 10-15m/min |

| Decoiler: | Manual/Hydraulic |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

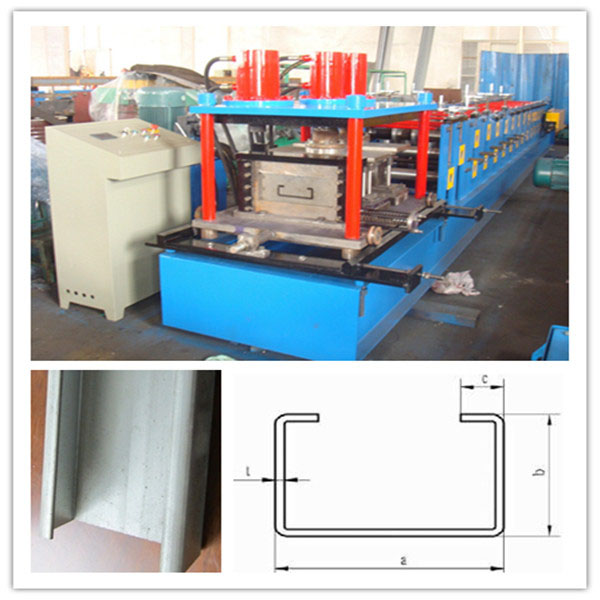

0.3-1.2mm Thickness Light Steel C U Purlins Stud And Track Roll Forming Machine Forming Speed 10-15m/min

Technical Parameter

| No. | Main parameter of roll forming machine | |

| 1 | Suitable to process | Galvanized steel or Customers' requirement |

| 2 | Width of the plate | As customer need |

| 3 | Thickness of the plate | 0.3-1.2mm |

| 4 | De-coiler | Manual one, can load 5 tons raw material |

| 5 | Rollers for forming | 12 rows |

| 6 | Diameter of the roller | Φ52mm |

| 7 | Rolling material | Steel 45# |

| 8 | Main motor power | 4kw |

| 9 | Productivity | 10-15m/min |

| 10 | Cutting method | Hydraulic mould cutting |

| 11 | Material of the cutting blade | Cr12 |

| 12 | Hydraulic cutting power | 3kw |

| 13 | Processing precision | Within 1.00mm |

| 14 | Control system | Delta PLC control |

| 15 | Side panel of machine | 14mm |

| 16 | Main structure of the machine | H steel |

| 17 | Weight | About 3.5T |

| 18 | Dimensions | 5.5*1.0*1.5m |

| 19 | Voltage | 380V 50Hz 3phases(changeable as needs) |

| 20 | Certificate | CE/ISO/SGS |

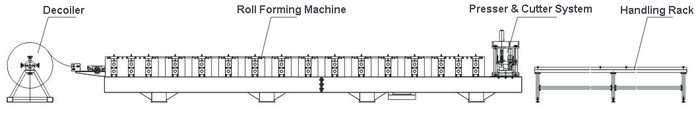

Machine Component

Working Flow of Roll Forming Machine

Decoiler --- Feeding & Leveling --- Roll Forming --- Cut-to-length

--- Run out table

Photo Gallery

Loading pictures

1. One 20 feet container for loading one set machine with

mechanical decoiler.

2. Main machine body and decoiler is load naked (tighten to

container with steel wire rope).

3. Spare parts and operating tools are loading in tooling box.

Our Exhibition

Our services

1.One-year warranty will be assured for all our machines. Moreover, We promise to provide permanent technical support and after-sales service with our customers.

2. We can design different kinds of profiles and fittings for machine, as per customer's requirements. You can send me the profile drawing and we will design the machine for you.

3. Every process will be checked by responsible QC which insures every product's quality.

4.Professional engineers are available to be sent to the customers' factory to install and debug the machines and train the staff how to operate and maintain the machines.

5. We warmly welcome you to visit our factory for more detailed information and inspecting our machines

|