| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Cable Tray Roll Forming Machine |

|---|---|

| Brand Name: | Sussman |

| Model Number: | SM-CT |

| Certification: | CE, SGS, ISO |

| Place of Origin: | Wuxi, China |

| MOQ: | 1 set |

| Price: | negotiable |

| Supply Ability: | 5 sets/month |

| Delivery Time: | 75 days after deposit |

| Packaging Details: | Film and steel |

| Material thickness: | 1.5-2.0mm |

| raw material: | Galvanized steel and black steel sheets |

| forming speed: | 10m/min |

| roller material: | GCr15 |

| Main motor power: | 18.5Kw |

| Hydraulic cutting power: | 11Kw |

| PLC: | Panasonic, Japan |

| Delivery time: | 75 days after receive deposit |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Cold Rolled Steel 11Kw Cable Tray Making Machine Servo Feeding 10 Meters / Min

Cable Tray Roll Forming Machine Roll Forming System:

Usage: In order to keep the product shape and precision, adopts

welded sheet structure, motor reducer drive, gear transmission,

roller surfaces polishing, hard plating , heat treatment and

galvanizational treatment.

Feature: Automatic cutting controlled by PLC. Ensure stability,

precision and cutting speed. It adopts the hydraulic drive and

automatic location to decide the dimension and cut the target

products.It contains one set of cutting tools, one hydraulic tank

and one cutter machine.

1. Equipment Structure and Technical Data

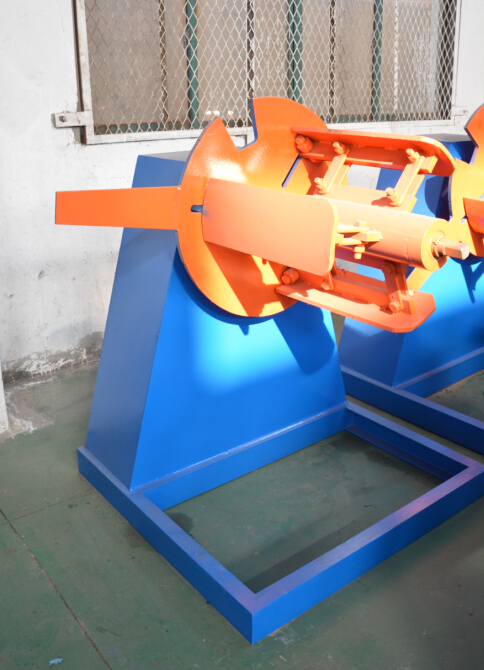

a. Decoiler

Capacity: 3 Tons manual

Max coil width: 1250mm

Diameter: 460-520 expansion

Expansion: passive

b. Levelling device

leveling raw material thickness: 1-2mm

Max leveling raw material width: 300mm

power: 3Kw

7 rolls levelling, 3 rolls up and 4 rolls down

diameter 80mm, chrome and HRC60 heat treatment to secure the smooth surface

C. Feeding device

Servo feeding can control the punching distance in precision, controlled by PLC, and the feeding tolerance can be +-0.05mm,the servo motor can control the speed, and can accept the input signal, and react quickly, and performance well, the touch screen can display the rotating speed, the length and the quality, it can be controlled by the manual and auto modes.

Servo feeding motor: about 2.9Kw Yaskawa

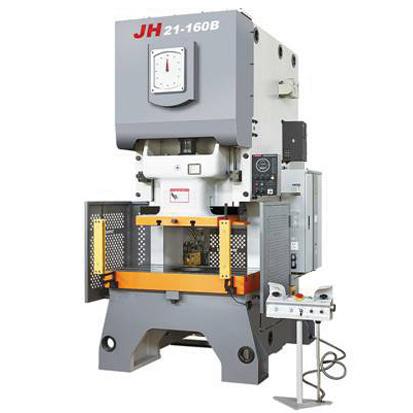

d. Press Machine

e. Main Roll Forming

f. Cutting

g. Out tables

2. Working Flow

Un-coiler ------ Levelling-----Feeding-----Punching --- Roll forming ----- PLC control --- Hydraulic Cutting---- Run Out Table

3. Machine list

| No. | Name | Quantity. |

| 1 | 3 tons manual de-coiler | 1 set |

| 3 | Roller Lever | 1 set |

| 4 | Servo feeding machine | 1 set |

| 5 | Punching Press machine 180 Ton | 1 set |

| 6 | Punching models | 2 sets |

| 7 | Roll forming machine | 1 set |

| 8 | PLC system with tough screen | 1 set |

| 9 | Post cutting device | 1 set |

| 10 | Collecting tables 3m | 2 sets |

| 11 | Toolbox | 1 set |

| 12 | Spare Parts | 1 set |

|