| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Plastic Injection Molding Machine |

|---|---|

| Brand Name: | MEPER |

| Model Number: | HM-300 |

| Certification: | CE/ISO9001:2008 |

| Place of Origin: | Ningbo,China |

| MOQ: | 1SET |

| Price: | Please Click Inquiry Button |

| Delivery Time: | 15-60working days |

| Packaging Details: | wooden pallet(standard) wooden case(option) |

| Suitable machine: | PE,PP,ABS |

| Injection weight: | 640g |

| tie-bar space: | 580*580mm |

| toggle stroke: | 550mm |

| Payment Terms: | T/T, L/C |

| Company Info. |

| VAINO INTERNATIONAL LIMITED |

| View Contact Details |

| Product List |

high speed power saving injection molding machine HM-300 for 4L Plastic pails

Enviromental protection-high energy saving

High performance energy saving result realized the reduction of cost

Not only save energy, but also realized the precise speed and pressure control

High efficiency, lower oil temperature ,make oil talk much smaller, extend the use of hydraulic oil and elements

HIGH ENERGY SAVINGS

Under normal operating conditions,compared with conventional hydraulic injection molding machines,energy saving of 20-80% can be achieved.

MOLDING STABILITY

Compared with conventional injection molding machines,repeatability is greatly improved due to ervo motor closed-loop control

QUICK RESPONSE

Featuring a dynamic servo motor with a response time of only 0.05sec

QUIET OPERATION

Machine runs much lower noise levels, particularly in low speed applications

RELIABLE HOLDING PRESSURE

Compared with traditional hydraulic machine,the holding pressure is more stable and does not have limitation

BETTER OIL TEMPERATRURE STABILITY

The servo system only delivers hydraulic oil as it is needed for the various functions,This prevents unnecessary generation of heat and substantially reduces oil cooling requirements.

Specification

| HM-300 | ||||

| INJECTION UNIT | UNIT | A | B | C |

| SCREW DIAMETER | mm | 55 | 60 | 65 |

| SCREW L/D RETIO | L/D | 22 | 20.2 | 18.6 |

| INJECTION VOLUME | cm3 | 677 | 805 | 945 |

| INJECTION WEIHGT | g | 616 | 733 | 860 |

| oz | 21.72 | 25.85 | 30.34 | |

| INJECTION RATE | cm3/ s | 266.8 | 317.5 | 372.6 |

| INJECTION PRESSURE | Mpa | 200 | 168 | 143 |

| CREW SPEED | rpm | 220 | ||

| CLAMPING UNIT | ||||

| CLAMPING FORCE | kN | 3000 | ||

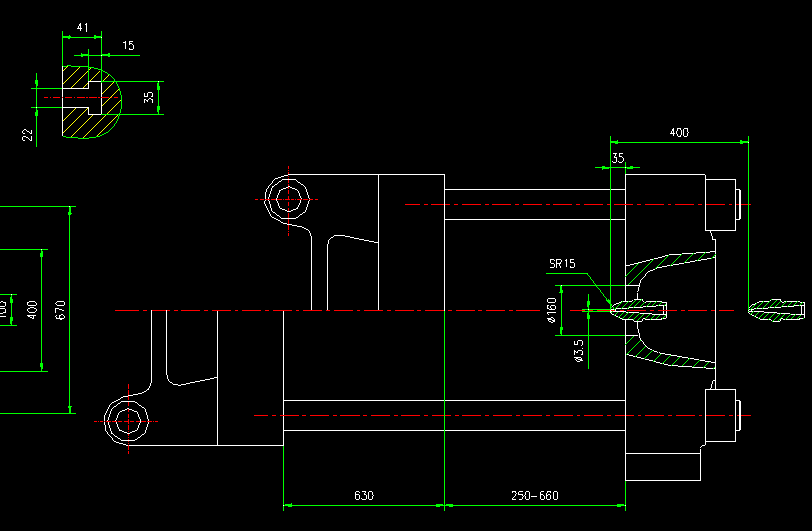

| MOLD OPEN STROKE | mm | 590 | ||

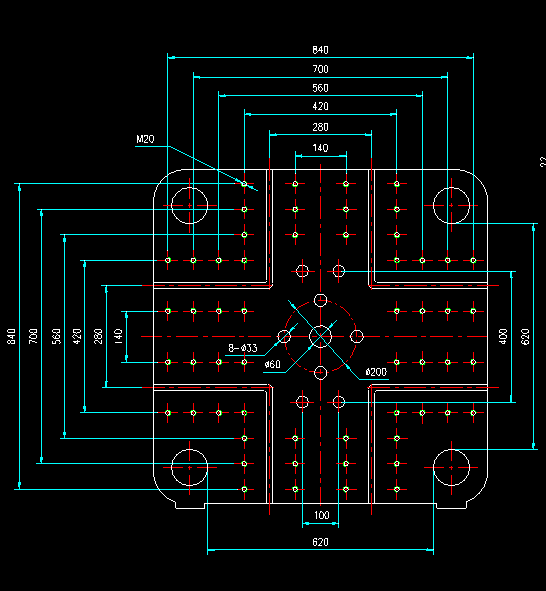

| SPACE BETWEEN TIE BARS | mm | 620×620 | ||

| MAX.MOLD HEIGHT | mm | 200~630 | ||

| EJECTOR STROKE | mm | 150 | ||

| EJECTOR FORCE | kN | 70 | ||

| OTHERS | ||||

| MAX.PUMP PRESSURE | Mpa | 16 | ||

| PUMP MOTOR POWER | kW | 30 | ||

| HEATER POWER | kW | 18.5 | ||

| MACHINE DIMENSIONS | mm | 6.1×1.7×2.4 | ||

| OIL TANK CAPACITY | L | 530 | ||

| MACHINE WEIGHT | t | 9.3 | ||

Advantage:

1. T Slot Platen;

2.Machine Weight more than most factory.

3.Machine base use rectangular Tube.

4.4pcs safe door are moveable,maintain the machine more easy;

5.Hydraulic tank is moveable,more easy to clean the tank,

6.heating band is made by cermics,use life is long

7.prepare more spare parts for customer

Platen drawing:

|