| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Salt Spray Corrosion Test Chamber |

|---|---|

| Place of Origin: | Guangdong, China (Mainland) |

| Brand Name: | HAIDA |

| Certification: | ISO 9001:2000; ISO 9001:2008; QS-9000; ISO 14001:2004; CE, , SMC, CMC, CPA, CE,CMA,IMC |

| Model Number: | HD-E808-90A |

| MOQ: | 1 Set |

| Price: | Negotiable |

| Packaging Details: | ach set protected with resin fiber and PP film, then put into Strong wooden case with operation man |

| Delivery Time: | 20 days after order confirmed |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,In cash, escrow |

| Supply Ability: | 300 Sets per Month Haida |

| Brine tank capacity: | 15L|25L |

| Equipment material: | P.V.C rigid plastic board |

| Lab volume: | 108L|270L |

| Temperature precision: | ±1℃ |

| Temperature range: | 35℃~55℃ |

| Temperature uniformity: | ≤±2℃ |

| Company Info. |

| Dongguan Haida Equipment Co.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

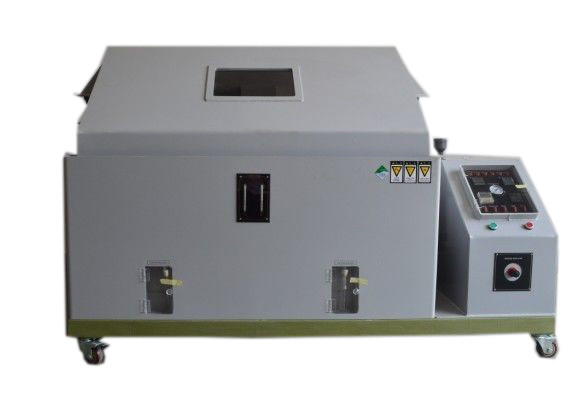

Plastic Board Salt Spray Corrosion Testing Chamber With Multiple

Safety Protection Device

1. Product introduction:

P.V.C Rigid Plastic Board Salt Spray Corrosion Testing Chamber is

is designed for surface treatment of corrosion-resistant capacity

test for various materials,including paint, electroplating, organic

and inorganic film, antirust oil,chemicaltreatment, and then

achieves a long period of resistance to corrosion products.

Ferrous and non-ferrous metals are attacked continuously by

humidity, acids, solutions, gases etc. It is therefore vitally

important to choose the correct surface protection. There are many

materials and qualities on the market and their properties must be

properly assessed. Materials intended to prevent corrosion must be

tested if failures are to be avoided. Furthermore the comparative

quality control during production is of increasing importance. The

best known processes employ spray vapour tests using various salt

solutions as well as condensation water climates.

P.V.C Rigid Plastic Board Salt Spray Corrosion Testing Chamber

3. Design standard:

CNS:3627,3385,4159,7669,8886;JIS:D0201,H8502,H8610,K5400,Z2371;

ISO: 3768,3769,3770;

ASTM:B117,B268.

Model | HD-E808-60A | HD-E808-90A | HD-E808-120A |

Inner box size: | 60×40×45 | 90×60×50 | 120×100×50 |

Outside box size: | 107×60×118 | 141×88×128 | 190×130×140 |

Equipment material: | Both internal and external material is using imported P.V.C rigid plastic board; the case cover is using transparent rigid plastic board P.V.C. | ||

Temperature range: | 35℃~55℃ | ||

Temperature fluctuations: | ≤±0.5℃ | ||

Temperature uniformity: | ≤±2℃ | ||

Temperature precision: | ±1℃ | ||

Test chamber temperature | NSS ACSS 35±1℃ CASS:50±1℃ | ||

Saturated air barrel temperature: | NSS ACSS 47±1℃ CASS 63±1℃ | ||

Brine temperature: | 35℃±1℃ | ||

Spray quantity: | 1.0~2.0 ml / 80cm2 / hr | ||

PH: | NSS ACSS6.5~7.2 CASS 3.0~3.2 | ||

Lab volume: | 108L | 270L | 600L |

Brine tank capacity: | 15L | 25L | 40L |

Power: | 1∮AC220V,10A | 1∮AC220V,15A | AC 1∮,220V,30A |

Multiple safety protection devices: | Water shortage/ over temperature / phase protection | ||

Standard accessories: | Test salt, measure bucket, tool etc 1 set | ||

Picture Show :

|