| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Pulp Tray Machine |

|---|---|

| Place of Origin: | CHINA |

| Brand Name: | HONGRUN |

| MOQ: | 1SET |

| Price: | negotiation |

| Packaging Details: | Standard Export Packaging |

| Delivery Time: | About 75 days |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 100SETS PER YEAR |

| Certification: | ISO9001, CE, SGS, BV, TUV |

| Model Number: | HRZ-6000M |

| Type: | full automatic rotary type |

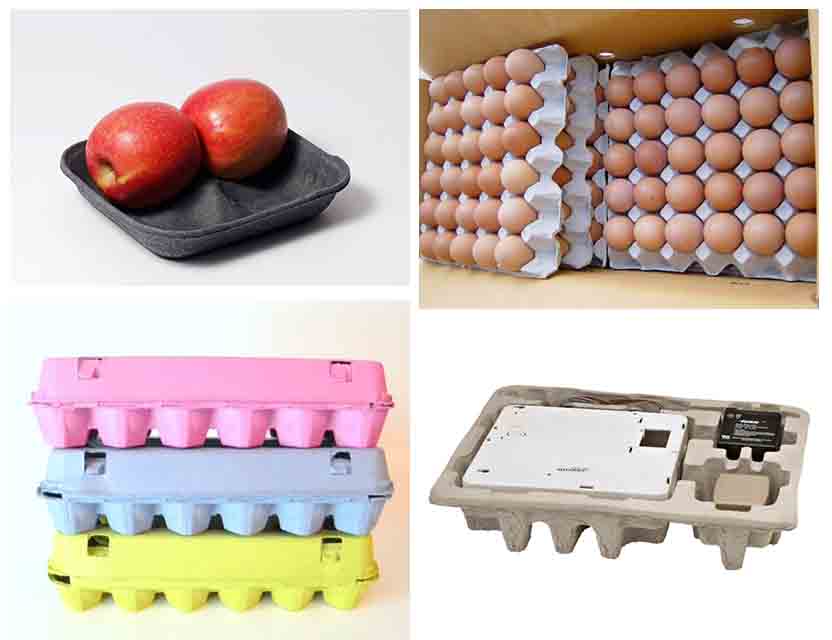

| Finished products: | egg tray /wine tray/yogurt tray /fruit tray/egg box ect. |

| After-sales service provided: | Engineers available to service machinery overseas |

| Color: | Customized Color |

| Warranty: | One Year |

| Condition: | New |

| Product type: | Egg Tray Machine |

| Dimension(l*w*h): | 30*4*4M |

| Capacity: | 6000pcs/hr |

| Raw material: | Recycled paper |

High Output Rotary Pulp Egg Tray Making Machine Egg Box Moulding Machine

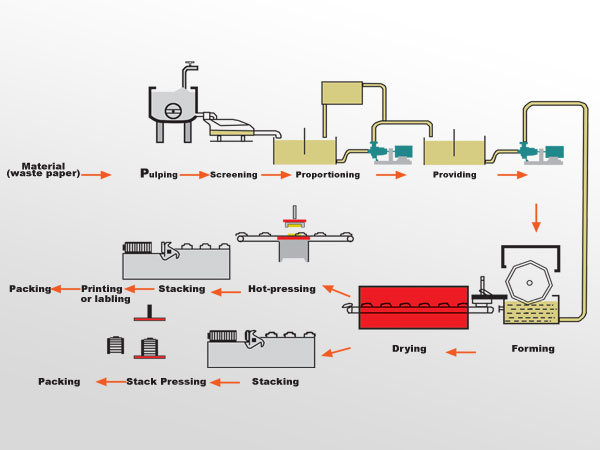

Machine introduction

1. This machine mainly produces the pulp molded products, such as egg tray ,egg box, fruit tray, coffee tray.

2, The material for the molded pulp products is waste paper, corrugated paper, waste newspaper, magazine.

3, The Molding machine part is 8 faces rotating drum, each surface has 3 moulds. So there are 24 moulds and others have 3 transfer moulds. The moulds material can use plastic or aluminous depend on buyer's request.

Main equipment

1. Pulp molding system: Hydraulic pulper, High-frequency vibration sieve frame, Pulp pump, Strengthening of self-priming pump, Agitator, Control cabinet of pulping system

2. Forming system: Rotary forming machine, Molds, Vacuum pump, Screw Air Compressor, Vacuum buffer tank, Air compressor storage tank, White Water pump, High-pressure water pump, Refiner machine, Power cabinet of forming system

3. Drying system: Conveyor, Blower, Induced fan, Burner, Bellows, etc

4. Packing system: Packing machine

Technical data

| Item | Information | Notes |

| Output Range | 6000pcs/h | 30 packed egg tray(60~80g) |

| Workshop recommendation | ≥600m2 | Length≥40m;Width≥15m;Height≥6m; (It could be adjusted according to the user's existing workshop) |

| Type of Material | Waste paper | Newspaper/Carton /Paper box/Books/ Corrugated paper/Kraft paper etc. |

| Material consumption | 360~480kg/h | 30 packed egg tray(60~80g) |

| Water consumption | 800-1050kg/h | 30 packed egg tray(60~80g) |

| Electricity consumption | 140-175kw/h | Full throttle operation |

Fuel consumption (approximately) | LPG 55~70 kg/h | 30 packed egg tray(60~80g) Choose one from these types of fuel |

| Natural gas 85~100 m3/h | ||

| Diesel 65~80kg/h | ||

| Operator Required | 5~8 person/shift | 24hours, 3shift |

| Container requirement for Transport | 5 of 40 HQ container + 1 of 20’GP container | Whole production line |

Operating Flow of egg tray machine

1.Preparation: Put the waste paper and water into hydraupulper,

when it forming pulp, put the pulp into first pulp pool, then the

pulp through refiner to the second pulp pool. Pulp Concentration:

water/waste paper 1000kg / 10kg

2.Open the air compressor, connect the reciprocating machine’s

power supply, then open the touch screen and into the operation

interface. In manual mode, press transferring molds enter,

transferring molds will be innermost of the reciprocating machine,

press the forming molds rise, forming molds and transferring molds

overlap.

3.Open pulp pump, when the pulp up to the overflow pulp slot

position, then open the vacuum pump, open the water valve of the

vacuum pump.

4.When the product good and stable, make the manual-automatic

switch of touch screen slide to automatic operation, the machine to

run automatically.

5.If need stop machine or the machine goes wrong, please

immediately close the Emergency Stop Switch or make the

manual-automatic switch slide to manual operation.

Feature of Egg Tray Making Production Line

| 1 | High automation, low labor cost |

| 2 | Low production cost |

| 3 | Energy saving(by 30%-50% compared with other manufacture) |

| 4 | Water saving(complete water treatment system equipped) |

| 5 | Efficient Multilayer dryer, saving space(by 33% compared with traditional dryer) |

| 6 | Stable final product quality(same weight, same dimention, strong and good look) |

Application

Delivery and packaging

|