| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Protein Ball Rolling Machine |

|---|---|

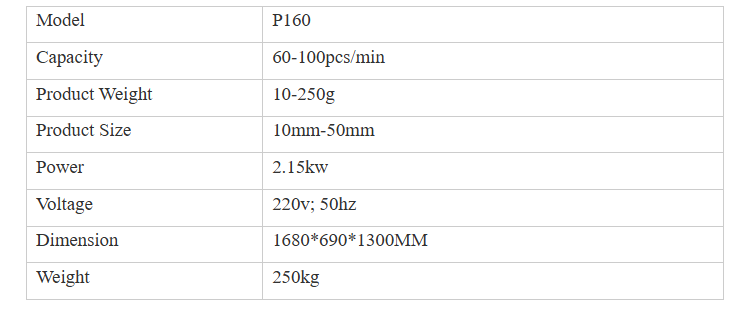

| Brand Name: | PAPA |

| Model Number: | P160 |

| Certification: | CE CERTIFICATE |

| Place of Origin: | CHINA |

| MOQ: | 1 Set |

| Price: | Negotiate |

| Payment Terms: | T/T |

| Supply Ability: | 80 sets |

| Delivery Time: | 25-30days |

| Packaging Details: | wooden case |

| Weight: | 250kg |

| Dimention: | 1680*690*1300MM |

| Power: | 1.75kW |

| Warranty Period: | 1 year |

| Material: | 304 tainless Steel |

| Voltage: | 220V |

| Capacity: | 60-90pcs/min |

| ball diameter: | 10-50mm |

| product weight: | 10-250g |

| Company Info. |

| Shanghai Papa Machine Technology Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Sticky date balls are a popular healthy snack made from dates, nuts, seeds, and natural sweeteners. To meet growing demand, manufacturers use automated sticky date ball production lines for high efficiency, consistency, and food safety compliance. This guide covers the key stages, machinery, and benefits of setting up a production line.

Machine working videos

Date Pitting & Soaking: Machines remove pits and soften dates for easier blending.

Nut Roasting (Optional): Enhances flavor before mixing.

Industrial Mixer: Combines dates, nuts, coconut, cocoa, or protein powder into a sticky dough.

Extrusion & Cutting: The dough is pressed and cut into uniform pieces.

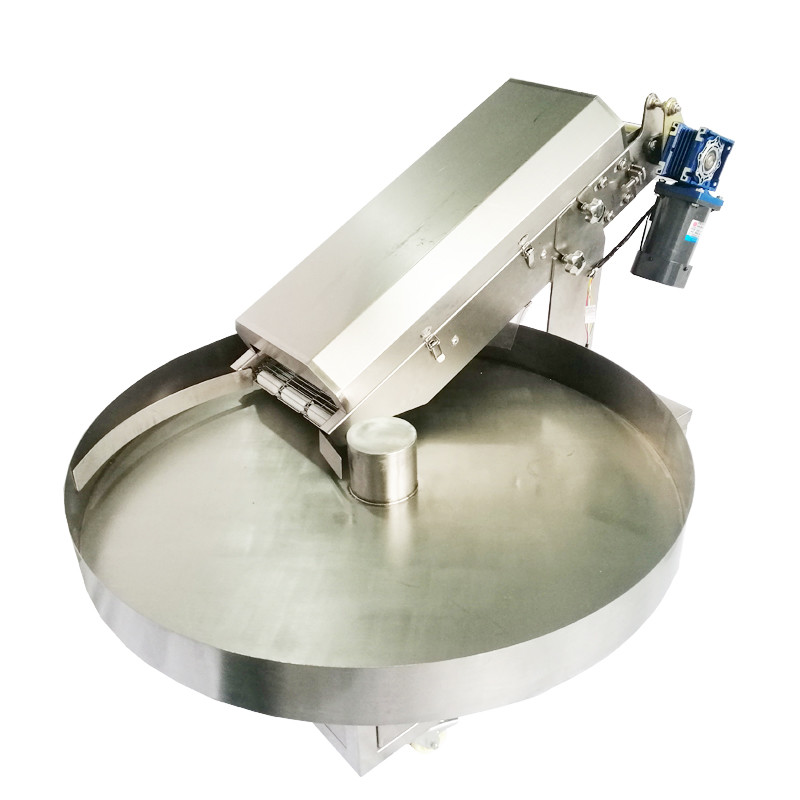

Ball Forming Machine: Shapes pieces into round balls (manual or automatic).

Alternative: Molding machines for bars or squares.

Coating Drum: Rolls balls in coconut, cocoa, or sesame seeds.

Chocolate Enrober: For premium chocolate-covered variants.

Cooling Tunnel: Stabilizes texture before packaging.

Dehumidifier (Humid Climates): Prevents excess moisture.

Flow Wrapper: Seals individual balls in eco-friendly packaging.

Metal Detector & Checkweigher: Ensures safety and weight accuracy.

✅ Higher Output – Produce 500–1,000 kg/hour with full automation.

✅ Consistent Quality – Uniform shape, size, and flavor in every batch.

✅ Food Safety Compliance – Meets HACCP, ISO 22000, and FDA standards.

✅ Customization – Easy to adjust recipes (vegan, keto, protein-enriched).

An optimized sticky date ball production line ensures efficiency, scalability, and premium product quality. Whether you're a startup or an established brand, automation helps meet market demand while keeping costs competitive.

|