Zhuhai Complord New Materials Co., Ltd. (Brand: Complord), located

in Gaolan Port National Petrochemical Industrial Park (Zhuhai,

Guangdong), has a total investment of 300 million RMB and an annual

production capacity of 22,000 tons of eco-friendly flame

retardants. More than 30% of the company's employees have a

bachelor's degree or above. The company collaborates with

institutes like the Chinese Academy of Sciences and Sun Yat-sen

University. Specializing in phosphorus-based, nitrogen-based, and

intumescent flame retardants (9 product series), its solutions are

applied in PP, PA, TPE substrates for appliances, automotive,

electronics, and cables. Certified with ISO9001, RoHS, and REACH

compliance, Complord holds multiple patents for high-performance

flame retardant technologies.

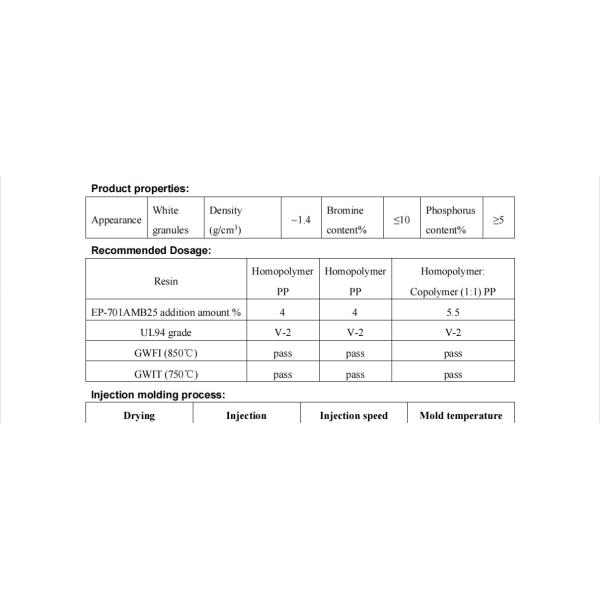

Product Introduction:

EP-701AMB25 is a new type of polyolefin low-halogen environmentally

friendly flame

retardant masterbatch with synergistic effects of nitrogen,

phosphorus and bromine. Compared

with traditional brominated flame retardants, EP-701AMB25 does not

contain Sb2O3, the addition

amount is small, and the flame retardant does not precipitate. When

4 % EP-701AMB25 flame

retardant masterbatch is added to the material, the product can

reach UL 94 V-2 (1.5mm ) level

and pass IEC 60695 glow wire GWIT 750℃ and GWFI 850℃ tests. In

addition, flame retardant

products have the characteristics of low density, low smoke

emission, and low mold corrosion,

and are mainly used to manufacture electrical sockets, electrical

frameworks, automotive

connectors and other products.

Advantage:

1. EP-701AMB25 is used in homopolymer PP, and adding 4% can reach

UL 94 V-2 flame

retardant level.

2. The addition of EP-701AMB25 masterbatch can solve the dust

problem in the powder flame

retardant production workshop, making the workshop tidier and

eliminating the risk of workers

inhaling powder.

3. EP-701AMB25 is used in PP, no antimony trioxide needs to be

added, and the flame retardant

does not precipitate.