| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | SMT Cleaning Equipment |

|---|---|

| Brand Name: | HSTECH |

| Model Number: | HS-600 |

| Certification: | CE,RoHS |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | 9000~12000usd/set |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Supply Ability: | 30 sets per month |

| Delivery Time: | 7~9 work days |

| Packaging Details: | Wooden case |

| Product name: | SMT Stencil Cleaning Machine |

| Other name: | Screen Printer Stencil Cleaner |

| Cleaning: | SUS304 Stainless steel |

| Stencil size: | Standard size 740*740*40mm, customized is available |

| Cleaning obejects: | Solder paste, red glue, flux, sosin,etc. |

| Cleaning solvent: | Alcohol |

| Drying function: | Yes |

| Machine dimension: | 980MM(L)*700MM(W)*1730MM(H) |

| Company Info. |

| Shenzhen Hansome Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Data sheet of Pneumatic stencil cleaner HS-600.pdf...

SMT Stencil Cleaning Machine with Counter and Emergency Stop Button

Machine introduction

This machine (Model:HS-600) we call it pneumatic SMT stencil cleaning machine, it's a automatic stencil cleaning equipment, with the cleaning and drying function combined. It's used in the SMT assembly process, designed for automatic cleaning solder paste steel mesh, red glue steel mesh, cooper mesh, resin screen,etc. It use the alcohol as the cleaning solvent, equiped with the 3 level filter system to achieve the solvent repeatly using, save the solvent consumption. This machine use the spray cleaning method for cleaning,powered by the air compressor, use the pump siphon the solvent and drive the spraying cleaning bars for double sides cleaning, the cleaning performance is very good.

Specification

| Model | HS-600 |

| Power supply | Compressor air |

| Application | stencil,metal mesh, steel mesh,cooper screen,gule screen |

| Stencil size | standard 29inch and below,740*740*40mm |

| Cleaning solvent | Alcohol |

| Cleaning liquid capacity | Max 45L,Min20L |

| Best cleaning fluid using volume | 40L |

| Liquid consumption | 120ml/pc |

| Cleaning method | Rotary double side pressure injection and high pressure air |

| Cleaning time | 2~4 Min Stencil and Copper Screen |

| Drying time | 2~5 Min |

| External air supply | 0.4Mpa~0.6Mpa |

| Consumer air quantity | 400~600L/Min |

| Air outlet size | φ125*25mm |

| Solder dross filter mode | 3 level filter(10um,5um,1um) |

| Weight | 305kg |

| Machine dimension | 980MM(L)*700MM(W)*1730MM(H) |

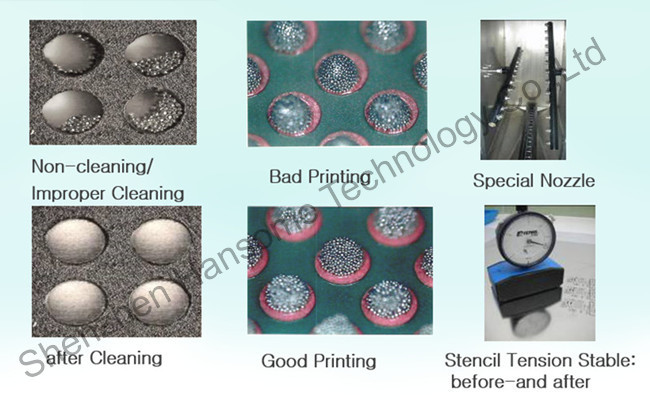

Cleaning performance

|