| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | CNC Custom Parts |

|---|---|

| Brand Name: | Yexin |

| Model Number: | CNC72-4 |

| Certification: | ISO9001:2015 |

| Place of Origin: | Dongguan, China |

| MOQ: | 1 pcs |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 150000 pcs/month |

| Delivery Time: | 3-10 work days |

| Packaging Details: | Standard Export Carton, Wooden Case, etc. |

| Application: | Medical, Construction, Agriculture, Aerospace, Manufacturing, Automotive, etc. |

| Material: | Stainless Steel, Aluminum, Brass, Copper, Plastic, Wood, etc. |

| Processing: | CNC Turning, Milling, Drilling, Wire EDM, Rapid Prototyping etc. |

| OEM/ODM: | Yes, Acceptable |

| Surface Finish: | Polishing, Painting, Anodizing, etc. |

| Tolerance: | ±0.01mm, ±0.001mm, etc. |

| Delivery: | Air, Sea, Express, etc. |

| Drawing Format: | CAD, PDF, STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, etc. |

| Equipment: | CNC Machining Centers |

| Keyword: | CNC Custom Parts |

| Company Info. |

| Dongguan Yexin Intelligent Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

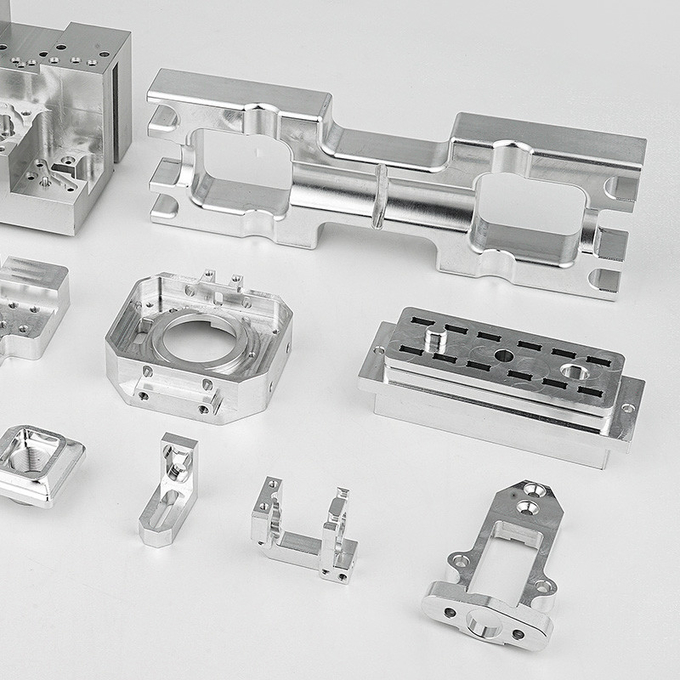

High Precision CNC Turning Parts Custom Stainless Steel CNC Machining Parts

CNC Milling Steel Parts

CNC machining is a subtractive manufacturing method employed to fabricate parts by cutting away

material from a workpiece or stock.

Precise instructions in the form of preprogrammed software and codes are input into the machine

to govern the movement of its tools and equipment.

CNC machining encompasses various machinery types, including turning mills, lathes, grinders,

and plasma-cutting machines.

Product Details

The cost of materials in CNC machining can fluctuate significantly due to the extensive array of

available options.

Each material carries its unique price tag, and the inherent physical properties of each material

play a substantial role in determining machining costs.

| Common Metal Materials for CNC Machining | |

| Metal Material | Properties |

| Aluminum | 2024: Good fatigue resistance and strength; excellent toughness at moderate to high strength levels; improved fracture toughness |

| 6061: Excellent machinability, low cost, and versatility | |

| 7075: High strength, hardness, low weight, and heat tolerance | |

| Stainless steel | Excellent machinability and outstanding uniformity; good workability and weldability, high ductility and formability |

| Steel Alloy | Mix of chromium, molybdenum, and manganese yields toughness, good torsional and fatigue strength |

| Brass | Versatile and highly attractive copper/zinc alloy with warm yellow color accommodates severe forming/drawing |

| Copper | High ductility and high electrical and thermal conductivity; develops attractive blue-green surface patina over time |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive, and medical industries |

| Steel Mild Low Carbon | High machinability and weldability, high stiffness; good mechanical properties, machinability, and weldability at low cost |

| Surface Finishes | ||

| Name | Applicable to | Machining marks |

| As machined | Metals, Plastics | Visible, light surface scratches |

| Smooth machining | ||

| Fine machining | Metals | Slightly visible |

| Polishing | Metals | Removed on primary surfaces |

| Bead blasting | Metals | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Metals | |

| Anodizing Type II | Aluminum | |

| Anodizing Type III | Aluminum | Visible under anodizing |

| Black oxide | Copper, Stainless steel, Alloy steel, Tool steel, Mild steel | Visible |

| Powder coating | Metals | Removed |

| Brushed + electropolishing | Stainless steel | Removed on Primary surfaces |

CNC Machining Applications

CNC machining is widely used throughout the aerospace, medical,

automotive industries for its ability

to rapidly manufacture precise parts in production-grade materials.

Typical CNC parts, include:

1. Housings and enclosures

2. Brackets

3. Fixtures for manufacturing

4. Gears and bearings

5. Internal mechanical components

6. Medical instrumentation

Company Profile

FAQ's

1. What is CNC Machining?

CNC machining is a subtractive manufacturing method employed to fabricate parts by cutting away

material from a workpiece or stock.

Precise instructions in the form of preprogrammed software and codes are input into the machine to

govern the movement of its tools and equipment.

CNC machining encompasses various machinery types, including turning mills, lathes, grinders,

and plasma-cutting machines.

2. Where Does CNC Machining Offer the Best Benefits?

CNC machining provides its most significant advantages when the following objectives are a priority:

1. Achieving greater precision in part manufacturing compared to

traditional methods.

2. Ensuring consistent and uniform dimensions in the produced

products.

3. Scaling up production to meet high volume demands.

4. Crafting intricate and complex designs efficiently.

5. Lowering overall manufacturing expenses.

3. How does our pricing compare to other suppliers?

When it comes to pricing, we offer a competitive advantage.

Typically, our prices for plastic injection mold tools and CNC machined/turned parts are 25-45% lower

than those of suppliers in North America and Europe.

In contrast to Chinese suppliers, we do not compete solely on price. Instead, we prioritize delivering

the utmost quality, rapid responsiveness, and professional results to our clients.

|